Method of producing a sodium iron(II)-hexacyanoferrate(II) material

A technology of hexacyanoferrate, iron acid, applied in chemical instruments and methods, ferricyanide, iron compounds, etc., to achieve the effect of minimizing energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

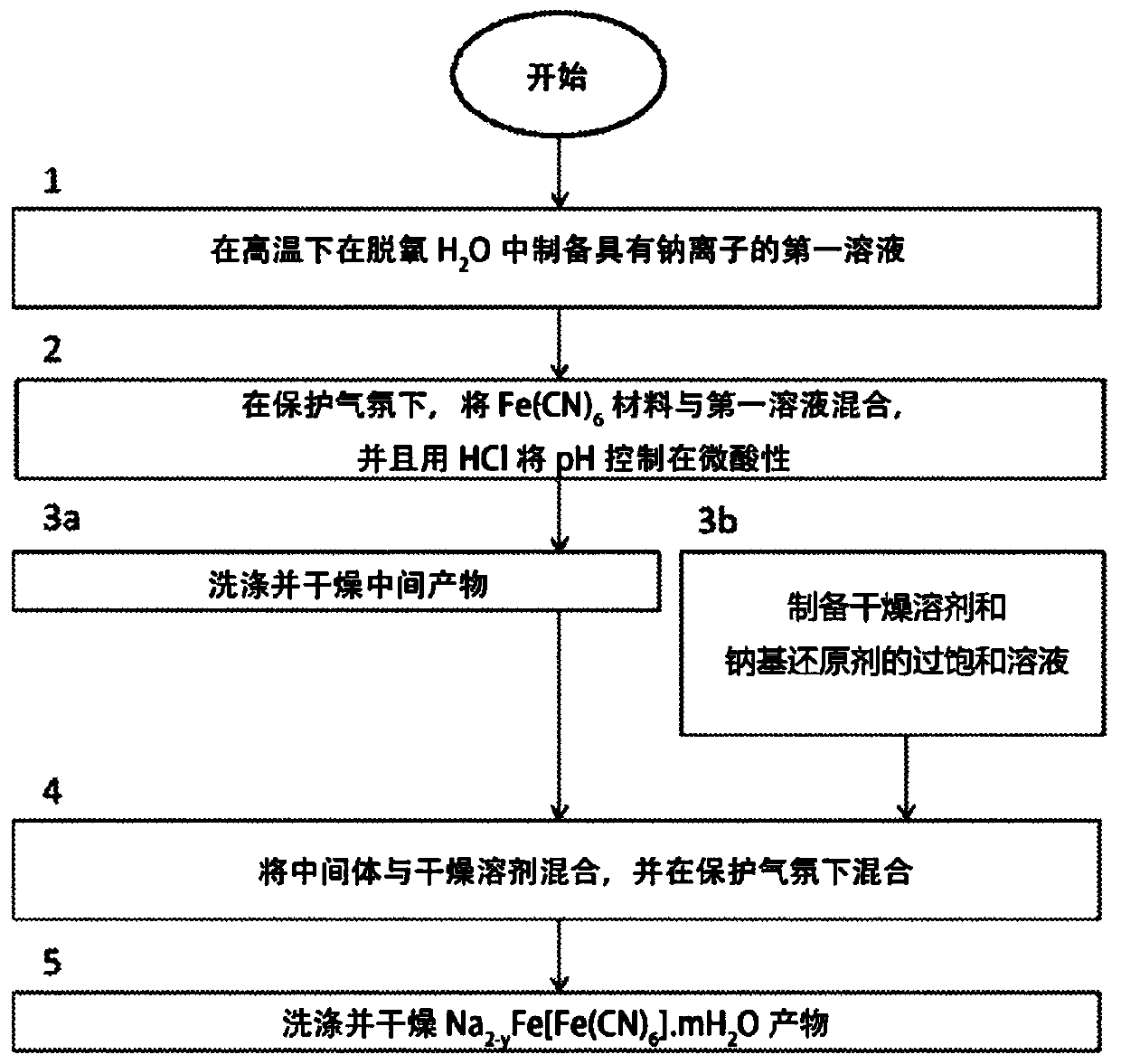

[0041] Production of ferric (II) sodium (Na) hexacyanoferrate (II) according to the present invention 2-y Fe[Fe(CN) 6 ].mH 2 O where y is less than x and preferably less than 0.2) method comprising two stages: (A) Na 4 Fe(CN) 6 The acid decomposes and dries into powder material, and (B) the sodium content of enriched powder material, Na 2-x Fe[Fe(CN) 6 ].mH 2 O, where x<0.4. The method according to the invention for producing a positive electrode for a sodium battery comprises a further stage (C) of forming an electrode comprising a sodium-enriched powder material.

[0042] The first stage (A) of the method according to the invention comprises Na 4 Fe(CN) 6 .10H 2 Acid decomposition of O, which is known in the art. However, it is a significant aspect that the chemical reactions taking place during the method according to the invention are carried out below 100°C and at or near ambient pressure. The reaction starts with Na 4 Fe(CN) 6 .10H 2 Acid decomposition of O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com