Chromium-base negative electrode active material for secondary lithium battery

A negative electrode active material and secondary lithium battery technology, applied in secondary batteries, battery electrodes, lithium storage batteries, etc., can solve the problems of cycle and low charge and discharge efficiency, and achieve high charge and discharge efficiency, good cycle, high Conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the negative electrode active material 1 of the chromium oxide of Li doping is prepared using liquid phase method

[0035] A certain amount of CrCl 3 Prepare a 1M aqueous solution with lithium nitrate according to the stoichiometric ratio shown in Table 1, heat it in a water bath to 50°C, add ammonia water dropwise to the above aqueous solution under vigorous stirring, and control the pH value at about 9.0. The obtained precipitate was separated by filtration five times with deionized water, and then dried at 100° C. for 12 hours. The dried precursor was pre-fired in an air atmosphere at 300 °C in a muffle furnace for 5 hours. Take out the ball mill and press into tablets. Then calcined at 500° C. for 6 hours and cooled to room temperature to obtain a series of final products of the negative electrode active material 1 for secondary lithium battery of the present invention, the average particle diameter of which is 50 nm.

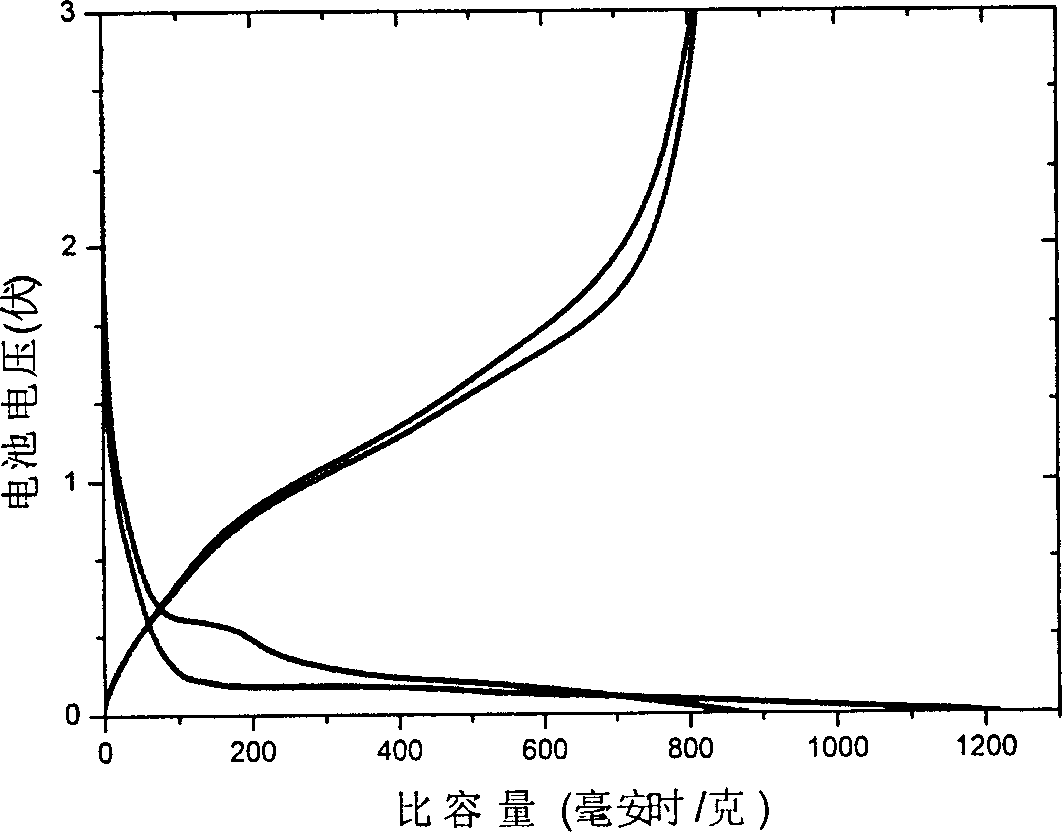

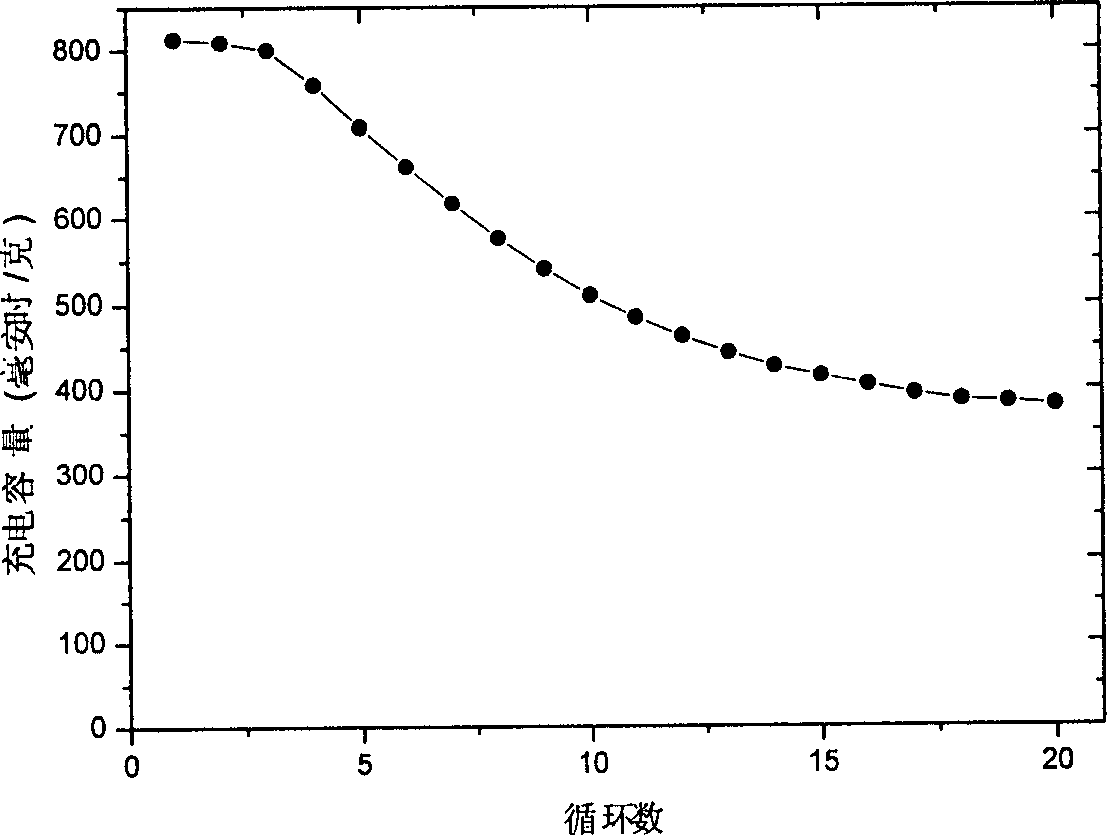

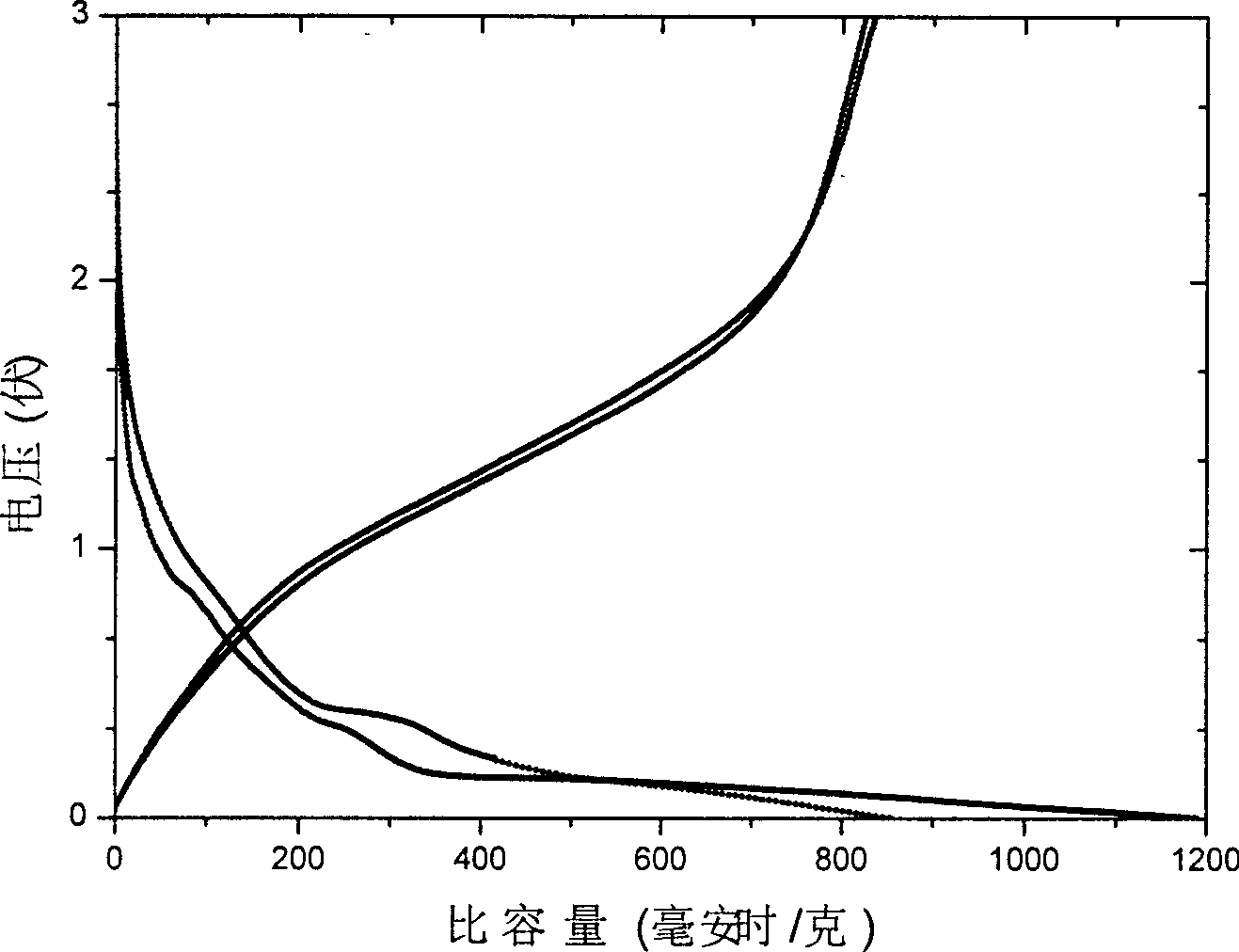

[0036] In order to study the ...

Embodiment 2

[0043] Example 2, Preparation of Li-doped chromium oxide / carbon core-shell structure composite material 2 by pyrolysis method

[0044](1) the product 1 prepared in Example 1 is mixed with carbon black (average particle diameter is 40 nanometers) as conductive additive in a weight ratio of 10:1, mechanical ball milling (rotating speed is 500 rev / min, 6 hours), Obtain internal composite particles; (2) mechanically grind the internal composite particles and sucrose at a weight ratio of 1:1 (rotating speed is 150 rpm, 1 hour), to obtain a uniformly dispersed mixture; (3) mix the mixture at high Pyrolysis under pure nitrogen, the steps of pyrolysis are: first use 4 hours to raise the temperature from room temperature to 400°C, then use 10 hours to raise the temperature from 400°C to 700°C, then keep the temperature at 700°C for 12 hours, and finally use 2 hours to cool down to At room temperature, the internal composite particles coated with the pyrolytic carbon layer were obtained...

Embodiment 3

[0046] Embodiment 3, the negative electrode active material 3 of the Ag-doped chromium oxide prepared by liquid phase method

[0047] According to the stoichiometric ratio shown in Table 1, a certain amount of CrCl 3 The negative active material 3 of Ag-doped chromium oxide was prepared by liquid phase method with silver nitrate, except that the dried precursor was calcined at 800°C for 12 hours, and the other parameters were the same as in Example 1, and a series of the present invention were obtained. The final product of the inventive negative electrode active material 3 for secondary lithium batteries has an average particle size of 200 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com