Asymmetric electrochemical capacitor and preparation method of asymmetric electrochemical capacitor

An electrochemical and asymmetric technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limiting asymmetric electrochemical capacitors, polluting the environment, and time consumption, and achieves easy promotion and high power Good density and circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

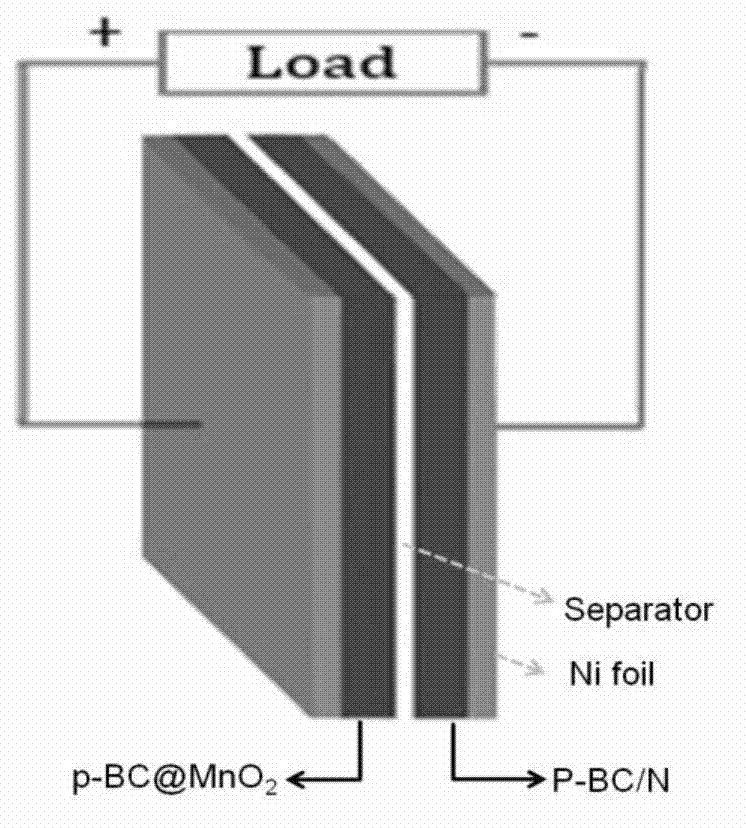

[0036] The present invention further discloses a method for preparing the above-mentioned asymmetric electrochemical capacitor, which includes the following steps:

[0037] Step a) Preparation of positive electrode material: put the pyrolyzed bacterial cellulose in KMnO 4 and K 2 SO 4 Shake and react in the mixed solution for a period of time to obtain the positive electrode material p-BCMnO 2 . In this step MnO 4 - Generation of MnO by oxidation of carbon on the surface of pyrolyzed bacterial cellulose 2 , and finally the surface-coated nano-MnO 2 Particulate Carbon Composite Cathode Material p-BCMnO 2 , in order to make the surface of the pyrolyzed bacterial cellulose covered with nanometer MnO as much as possible 2 Microparticle coating, the shaking reaction time is preferably 0.5h-2.5h, the temperature is preferably 20°C-60°C, and the rotation speed is preferably 50rpm-300rpm. Due to the three-dimensional porous network structure and high conductivity of the pyrol...

Embodiment

[0047] 1. Preparation of cathode material:

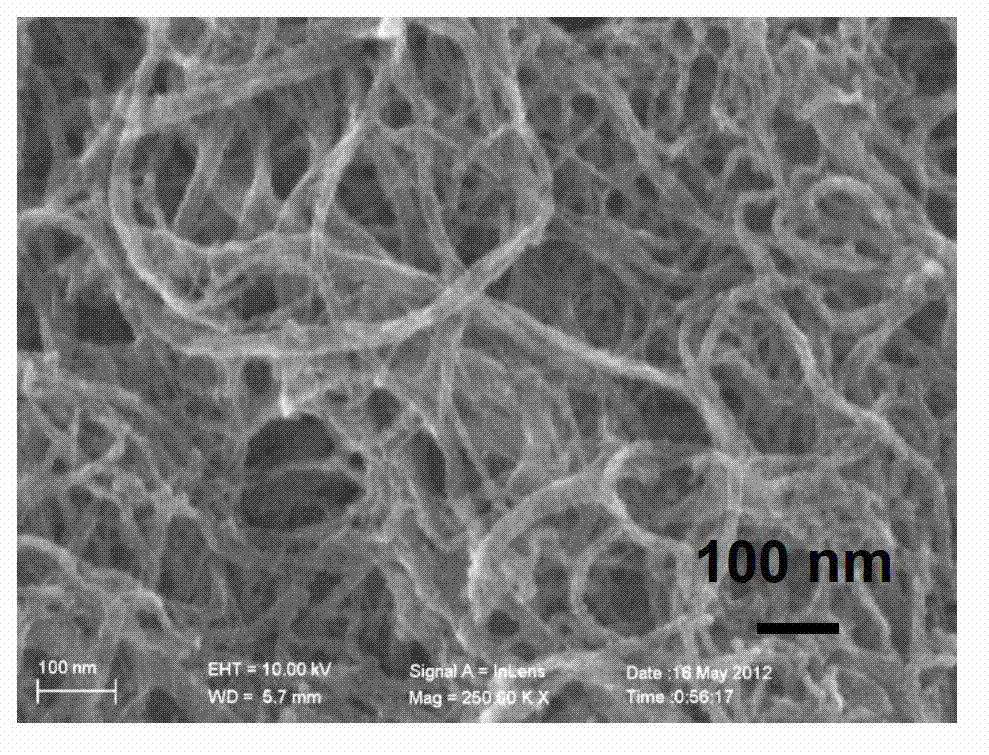

[0048] Bacterial cellulose (BC) was frozen with liquid nitrogen for 1 hour, then freeze-dried in a freeze dryer at a pressure of 0.04 mbar for 4 days, and then pyrolyzed at 1000 °C for 2 hours under nitrogen protection to obtain pyrolyzed bacterial cellulose ( p-BC).

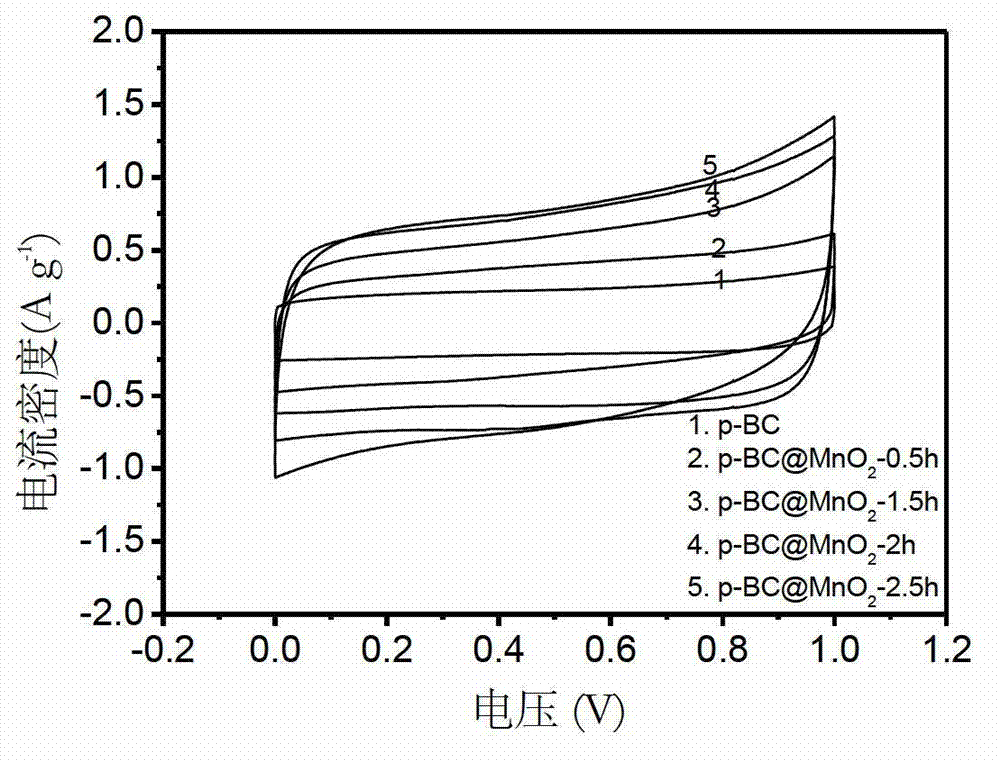

[0049] Weigh four pieces of 2-3mg p-BC materials and soak them in four pieces of 30mL KMnO 4 and K 2 SO 4 The beaker of the mixed solution, in which KMnO 4 The concentration is 0.1mol / L, K 2 SO 4 The concentration of the solution is 0.1mol / L, react in a shaking table at 100rpm at 30°C for 0.5h, 1.5h, 2h, and 2.5h respectively, after the reaction, wash with deionized water until the washing liquid is colorless, and obtain the positive electrode material p -BCMnO 2 . In order to distinguish the cathode materials prepared under different reaction times, p-BCMnO is used in the following description 2 -xh represents the positive electrode material, where x represe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com