Nickel doped cobaltosic oxide nanometer flower-shaped composite material, preparation method and application thereof

A technology of tricobalt tetroxide and composite materials, which is applied in cobalt oxide/cobalt hydroxide, electrochemical generators, electrical components, etc., can solve problems such as not being able to meet high energy density, and achieve low raw material costs, high product stability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 0.0314 g of Ni(NO 3 ) 2 ﹒ 6H 2 O was dissolved in 50 ml ethanol to form solution A, and 3.480 g of cobalt nitrate hexahydrate Co(NO 3 ) 2 ﹒ 6H 2 O was dissolved in a mixed solution of 25 ml ethanol and 25 ml water to form a solution B, and the solutions A and B were ultrasonically treated for 30 min;

[0026] (2) Mix solution A and solution B, stir, and add 4.320 g urea CO(NH 2 ) 2 , and keep stirring for 30 min;

[0027] (3) Put the mixed solution obtained above in a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 120 °C for a reaction time of 5 hours;

[0028] (4) After the reaction, the precipitate was washed with ethanol and distilled water in turn, and dried at 90°C for 12 hours;

[0029] (5) The powder sample obtained above was placed in a muffle furnace and calcined at 350° C. for 2 hours to obtain a nickel-doped cobalt trioxide nanoflower composite material with good crystallinity.

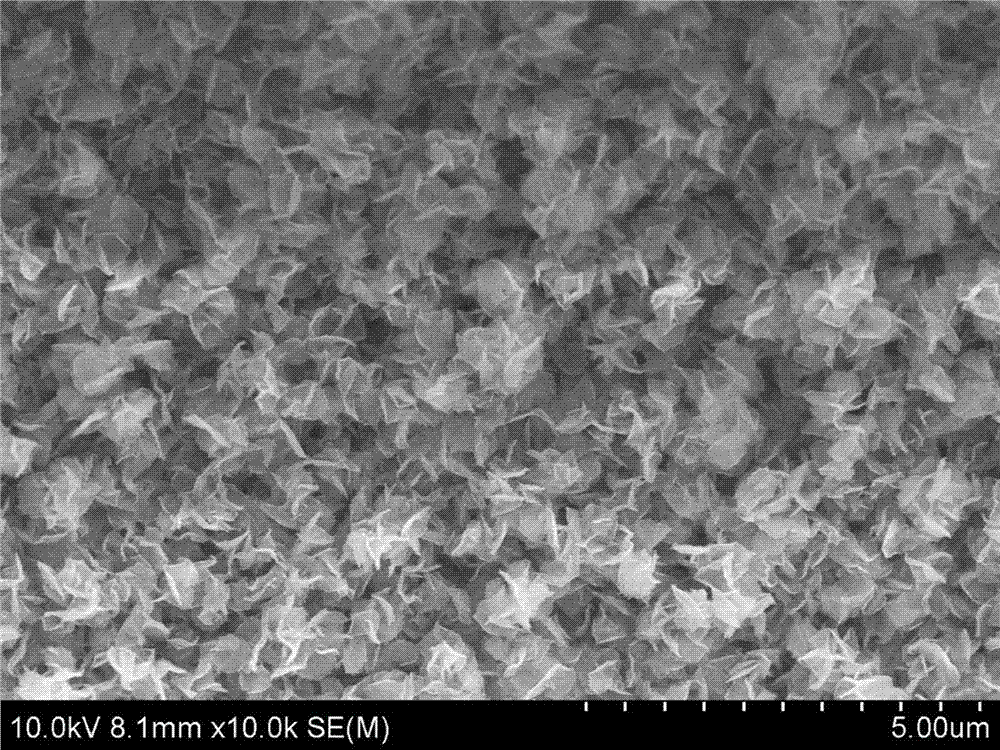

[0030] figure 1 Scanning electron...

Embodiment 2

[0032] (1) Weigh 0.066 g of Ni(NO 3 ) 2 ﹒ 6H 2 O was dissolved in 50 ml ethanol to form solution A, and 4.5956 g of cobalt chloride hexahydrate CoCl was weighed 2 ﹒ 6H 2 O was dissolved in a mixed solution of 25 ml ethanol and 25 ml water to form a solution B, and the solutions A and B were ultrasonically treated for 30 min;

[0033] (2) Mix solution A and solution B, stir, and add 3.423 g urea CO(NH 2 ) 2 , and keep stirring for 30 min;

[0034] (3) The mixed solution obtained above was placed in a polytetrafluoroethylene reactor, and hydrothermal reaction was carried out at 100 ° C, and the reaction time was 8 hours;

[0035] (4) After the reaction, the precipitate was washed with ethanol and distilled water in turn, and dried at 90°C for 12 hours;

[0036] (5) The powder sample obtained above was placed in a muffle furnace and calcined at 350° C. for 2 hours to obtain a nickel-doped cobalt trioxide nanoflower composite material with good crystallinity.

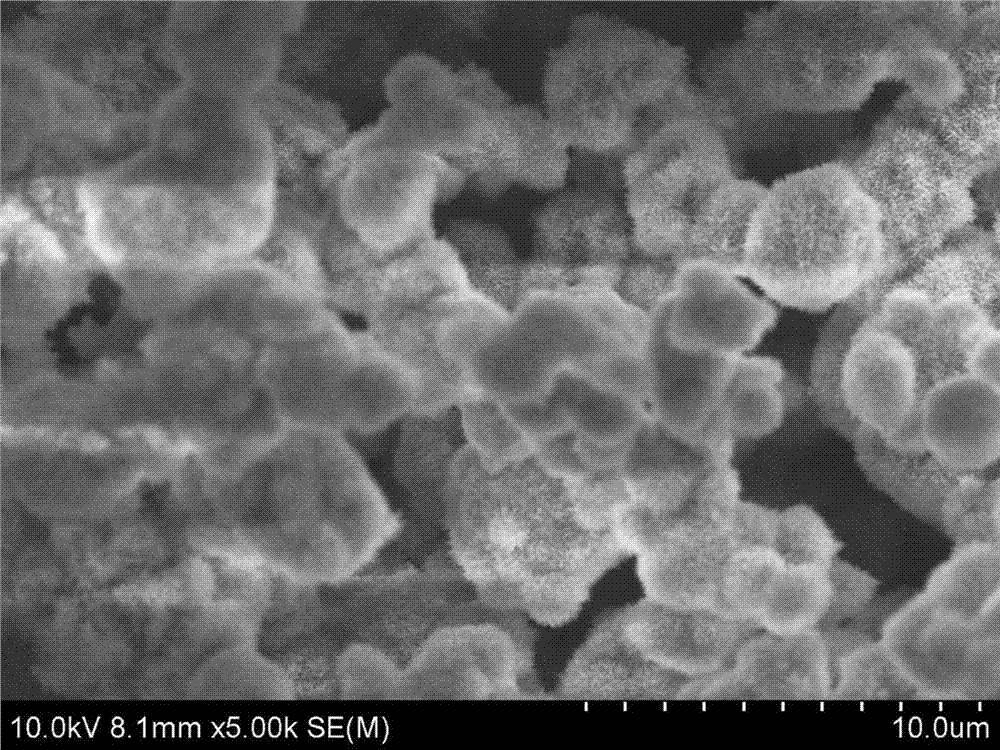

[0037] ...

Embodiment 3

[0039] (1) Weigh 0.0520 gNi(NO 3 ) 2 . 6H 2 O was dissolved in 50 ml ethanol to form solution A, and 1.9244 g of cobalt acetate tetrahydrate Co(CH 3 COO) 2 ﹒ 4H 2 O was dissolved in a mixed solution of 25 ml ethanol and 25 ml water to form a solution B, and the solutions A and B were ultrasonically treated for 30 min;

[0040] (2) Mix solution A and solution B, stir, and add 4.625 g urea CO(NH 2 ) 2 , and keep stirring for 30 min;

[0041] (3) Put the mixed solution obtained above in a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 180 °C for a reaction time of 3 hours;

[0042] (4) After the reaction, the precipitate was washed with ethanol and distilled water in turn, and dried at 90°C for 12 hours;

[0043] (5) The powder sample obtained above was placed in a muffle furnace and calcined at 350° C. for 2 hours to obtain a nickel-doped cobalt trioxide nanoflower composite material with good crystallinity.

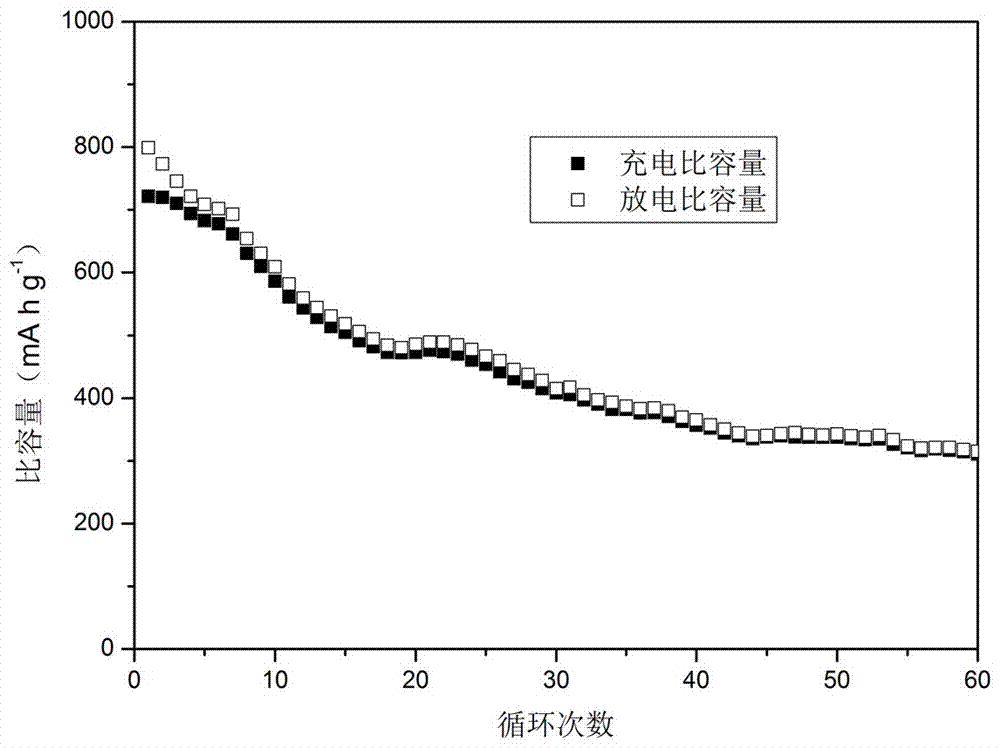

[0044] image 3 It is the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com