Ultrafine chip high-pressure tantalum powder production process

An ultra-fine flake type, medium and high pressure technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of not using hydrogenation and dehydrogenation processes, unfavorable production quality and production efficiency, easy introduction of impurities, etc., to shorten production. The effect of time, low production cost and process safety

Active Publication Date: 2018-05-29

江门富祥电子材料有限公司

View PDF11 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Chinese patent CN 104858436A relates to a method for preparing tantalum powder for high-reliability and high-capacity electrolytic capacitors, which specifically includes the following steps: raw material tantalum powder preparation, tablet production, pickling and impurity removal, and subsequent treatment of the flaky raw powder. Using hydrogenation and dehydrogenation processes

The raw material of this patent is tantalum powder that has been pretreated by sodium r

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

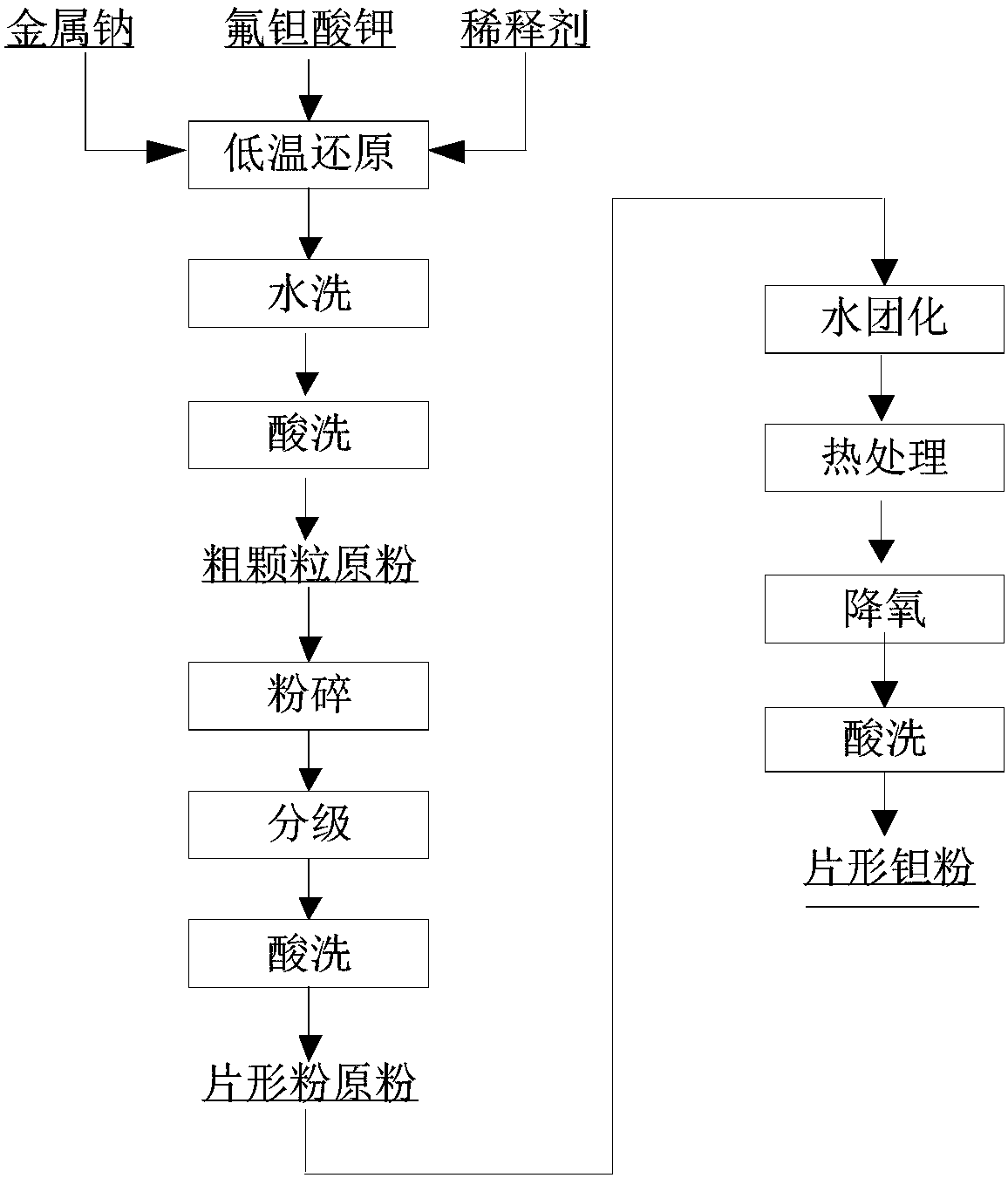

The invention provides an ultrafine chip high-pressure tantalum powder production process. The ultrafine chip high-pressure tantalum powder production process comprises the steps of controlling a sodium reduction process to prepare coarse-granule raw powder in a specific shape, mechanically pulverizing and grading the raw powder, screening out required chip powder, and performing acid pickling, thermal treatment and deoxygenation on the obtained chip powder to obtain finished chip powder. Compared with other disclosed chip tantalum production processes, the ultrafine chip high-pressure tantalum powder production process saves hydrogenation and stirred ball milling chip production processes, thereby being short in technical process, high in recovery rate, low in production cost and safe andenvironmentally friendly in technique.

Description

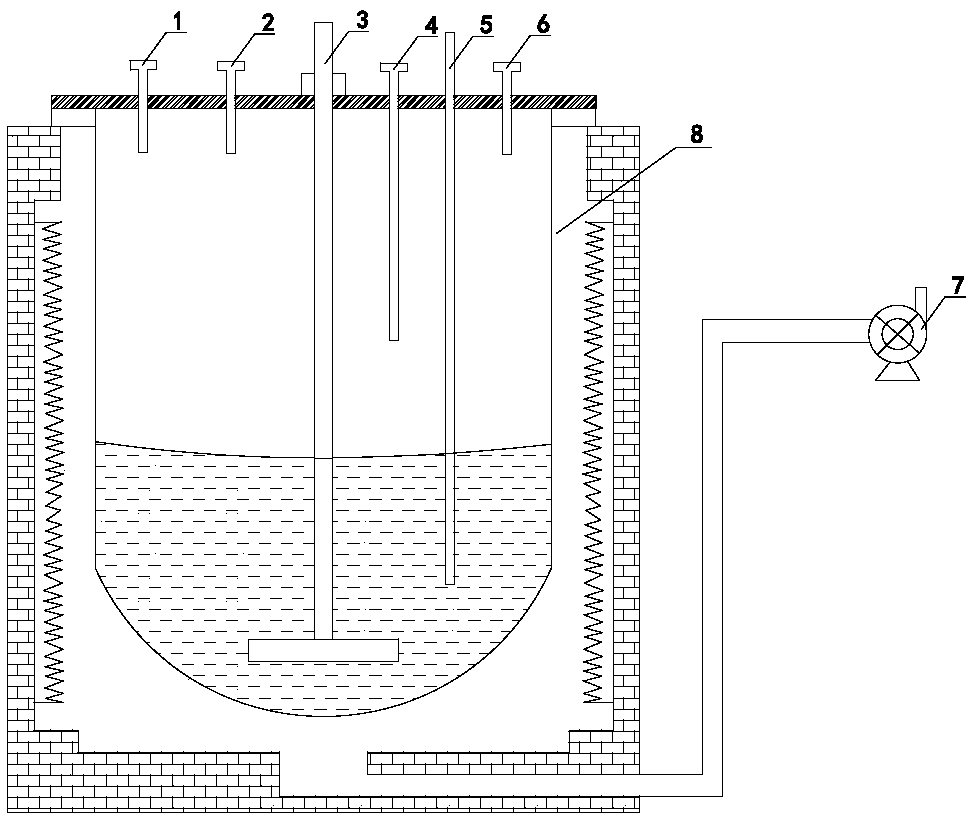

technical field [0001] The invention relates to a new production process of tantalum powder for capacitors, in particular to a new production process of chip tantalum powder for capacitors. Background technique [0002] Tantalum (Ta) powder is used to manufacture high reliability tantalum electrolytic capacitors. These capacitor elements are used in various fields such as: automation, electronic communication and computers. The latest requirements in these areas: The fundamental properties of tantalum powders must be improved to make it possible to use these components in extreme environments. It is well known that the chemical composition and physical morphology of tantalum powder will have a great influence on the performance of the completed tantalum capacitor, including, for example: withstand voltage, DC leakage current, reliability and equivalent series resistance (ESR). [0003] Currently, most tantalum powders are produced by chemical reduction of potassium fluorot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22F9/24B22F9/04B22F1/00

CPCB22F9/04B22F9/24B22F2009/041B22F2998/10B22F1/068B22F1/142B22F1/145

Inventor 王帆朱德忠廖志刚郑浩宇

Owner 江门富祥电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com