Method for preparing kaolin in-situ crystallization ZSM-5 molecular sieve

A technology of ZSM-5 and kaolin, which is applied in the field of synthesis and preparation of ZSM-5 molecular sieves, can solve problems such as low crystallinity and difficulty in reaching the level of industrial application, and achieve good stability, super strong vanadium-capturing passive nickel performance, Strong anti-metal pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

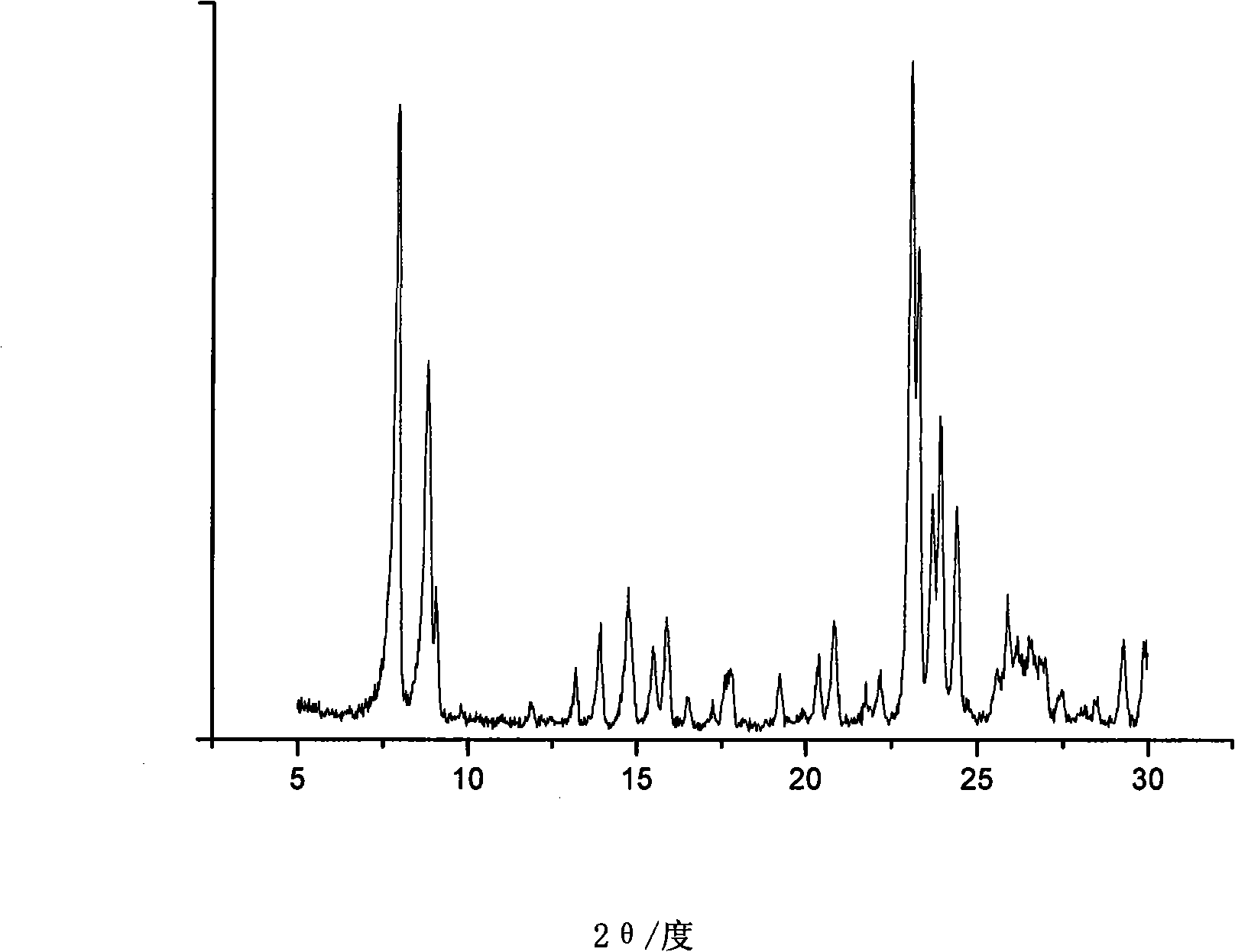

Image

Examples

Embodiment 1

[0043] Take 100 grams of kaolin, add 12 grams of sodium silicate and 86 grams of silica sol, mix well, grind, then put it into a muffle furnace, and roast at 1000 ° C for 3 hours to obtain roasted kaolin powder.

[0044] Add 108 grams of deionized water in the three-necked flask, then add 0.8 grams of NaOH and 13.31 grams of TPABr successively under stirring, and then add 60 grams of the above-mentioned roasted kaolin micropowder and 6.84 grams of pseudo-boehmite after stirring for 10 minutes, and stir for 10 minutes Then add 8.19 grams of NaCl successively, and the silicon-aluminum ratio is (SiO 2 / Al 2 o 3 ) is 3.80 grams of ZSM-5 molecular sieve of 40 as crystal seed. Stir for 10 minutes, then use sulfuric acid solution to adjust the pH value of the mixed slurry to 10, then raise the temperature of the reaction mixture to 30°C and stir for 2 hours, then transfer the mixture to a high-pressure crystallization kettle for crystallization at 150°C for 24 hours. After the rea...

Embodiment 2

[0046] Take 100 grams of kaolin, add 15 grams of sodium carbonate and 30 grams of silica gel powder, mix well, extrude into pellets, put them into a muffle furnace, and roast at 1100°C for 3 hours to obtain roasted kaolin pellets.

[0047] Add 72 grams of deionized water in the container, then add 0.96 grams of NaOH and 10.38 grams of TBAOH successively under stirring, and then add 53.33 grams of the above-mentioned roasted kaolin pellets and 16.15 grams of water glass after stirring for 10 minutes. Add 12.64 grams of NaCl, the ratio of silicon to aluminum is (SiO 2 / Al 2 o 3 ) is 8.27 grams of 40 ZSM-5 molecular sieves as seed crystals. Stir for 10 minutes, then use sulfuric acid solution to adjust the pH value of the mixed slurry to 10.5, then raise the temperature of the reaction mixture to 40°C and stir for 4 hours, then transfer the mixture to a high-pressure crystallization kettle for crystallization at 160°C for 30 hours. After the reaction, the product is filtered, ...

Embodiment 3

[0049] Take 1,000 grams of kaolin, add 2,000 grams of water, 500 grams of water glass, and 100 grams of silica sol. Grind with a ball mill for 60 minutes, and then use a small spray drying spray to form a sample of 960 grams. The sample is analyzed for particle size, and the content of 40-149um is 92%. The diameter is 63um. Kaolin microspheres were calcined in a muffle furnace at 1200° C. for 3 h to obtain calcined kaolin microspheres.

[0050] Add 64.8 grams of deionized water in the container, then add 1.12 grams of NaOH and 5.85 grams of n-butylamine successively under stirring, and then add 32.98 grams of the above-mentioned roasted kaolin microspheres and 20.77 grams of water glass after stirring for 10 minutes, and stir for 10 minutes Afterwards, 14.74 grams of NaCl and 1.48 grams of ZSM-5 molecular sieves with a silicon-aluminum ratio of (SiO2 / Al2O3) of 40 were added successively as seed crystals. Stir for 10 minutes, then use sulfuric acid solution to adjust the pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com