Denitration catalyst with SBA-15/TiO2 serving as carrier and preparing method thereof

A denitrification catalyst and carrier technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex flue gas components, low mass transfer efficiency, small specific surface area, etc., and achieve a wide activation temperature window , good mass transfer performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

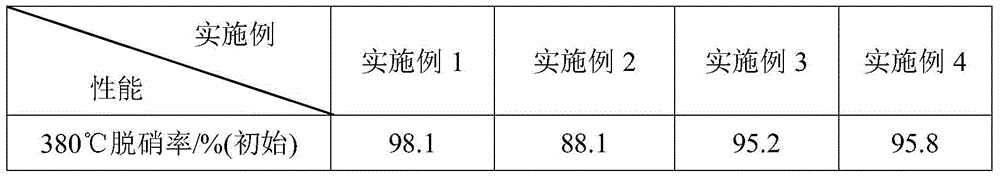

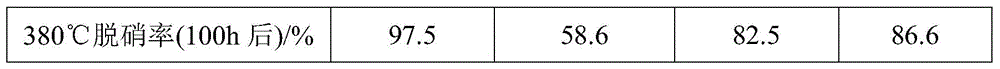

Examples

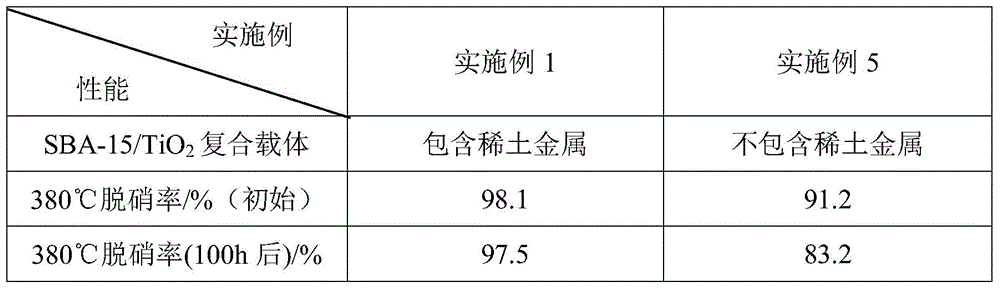

Embodiment 1

[0021] Using multi-block copolymer P123 as a template, ethyl orthosilicate as a silicon source, lanthanum nitrate as a precursor of La, and adjusting the pH value with hydrochloric acid, the SBA-15 molecular sieve with a framework containing rare earth metal element La was prepared by hydrothermal synthesis , based on the mass calculation of SBA-15 molecular sieve, the mass percent content of the rare earth metal element La is 5wt%; wherein, the specific steps of the hydrothermal synthesis method are: dissolving the triblock copolymer P123 in the hydrochloric acid solution, and then, sequentially Add lanthanum nitrate solution and ethyl orthosilicate, stir for 1 hour, transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal kettle, crystallize at 100°C for 20 hours, filter after cooling, wash with water and ethanol, and heat at 80°C Drying for 2 hours, and roasting at 450°C for 3 hours, the SBA-15 molecular sieve whose framework contains rare earth metals was...

Embodiment 2

[0026] Design a comparative test, the basic steps are the same as in Example 1, the difference is that the carrier used is the SBA-15 carrier containing the rare earth metal element La, rather than SBA-15 / TiO 2 Composite carrier, the specific steps are: use multi-block copolymer P123 as template agent, ethyl orthosilicate as silicon source, lanthanum nitrate as La precursor, adjust pH value with hydrochloric acid, and prepare skeleton containing rare earth metal by hydrothermal synthesis The SBA-15 molecular sieve of the element La, based on the mass calculation of the SBA-15 molecular sieve, the mass percentage content of the rare earth metal element La is 5wt%; wherein, the specific steps of the hydrothermal synthesis method are: dissolving the triblock copolymer P123 in hydrochloric acid solution, then add lanthanum nitrate solution and ethyl orthosilicate in sequence, and after stirring for 1 hour, transfer the mixture to a polytetrafluoroethylene-lined hydrothermal kettle,...

Embodiment 3

[0031] Design comparative experiments, the basic steps are basically the same as in Example 1, the difference is that the mechanical method is used to prepare SBA-15 / TiO 2 carrier, the specific steps are:

[0032] Using multi-block copolymer P123 as a template, ethyl orthosilicate as a silicon source, lanthanum nitrate as a precursor of La, and adjusting the pH value with hydrochloric acid, the SBA-15 molecular sieve with a framework containing rare earth metal element La was prepared by hydrothermal synthesis , based on the mass calculation of SBA-15 molecular sieve, the mass percent content of the rare earth metal element La is 5wt%; wherein, the specific steps of the hydrothermal synthesis method are: dissolving the triblock copolymer P123 in the hydrochloric acid solution, and then, sequentially Add lanthanum nitrate solution and ethyl orthosilicate, stir for 1 hour, transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal kettle, crystallize at 100°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com