Recycling method of mother liquor for SAPO-34 molecular sieve synthesis

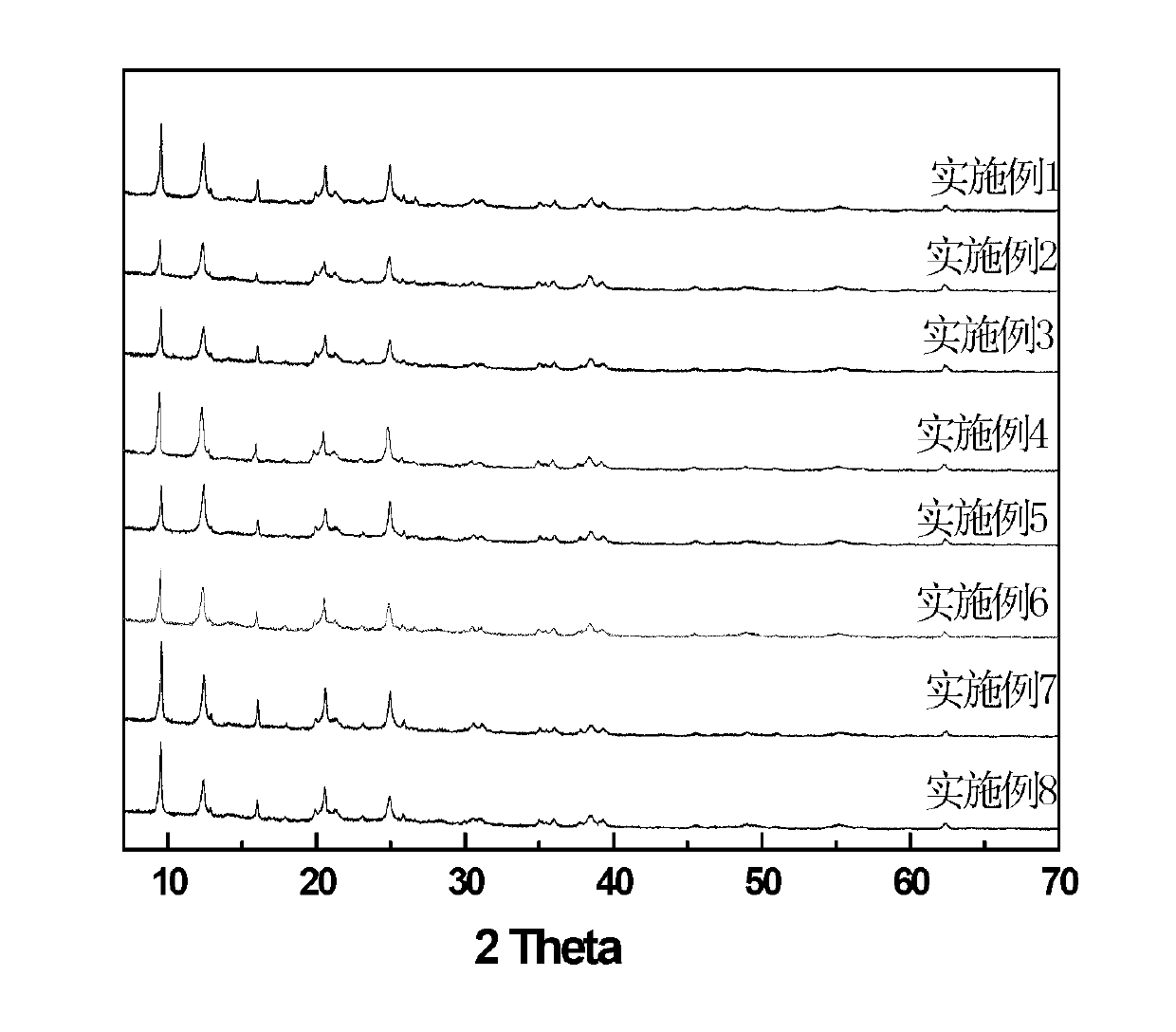

A SAPO-34, a technology for synthesizing mother liquor, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems such as the influence of catalyst performance, and achieve the effect of reducing production cost and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 1.07kg of pseudo-boehmite, 0.41kg of phosphoric acid, 0.22kg of roasted kaolin, 11.9kg of water in proportion to the 12kg mother liquor obtained by crystallization and separation after hydrothermal synthesis of SAPO-34. After stirring for 2 hours, add 4.5 kg of kaolin, 3.2kg of silica sol, 0.5kg of graphite powder and 1.3kg of water were mixed and then sheared and sprayed to form solid microspheres. Add 33.75g of solid microspheres, 33g of triethylamine and 35.35g of water into a stainless steel reaction kettle, place the kettle in a homogeneous reactor at 200°C for crystallization for 24 hours, cool, centrifuge, and dry to obtain catalyst microspheres.

Embodiment 2

[0035] The preparation process of this example is the same as that of Example 1, except that the spray-formed microspheres are calcined at 300° C. for 2 hours and then subjected to hydrothermal crystallization treatment.

Embodiment 3

[0037]The preparation process of this example is the same as that of Example 1, and the difference is that 1.07kg of alumina, 0.61kg of phosphoric acid, 0.4kg of silicon oxide, and 13.5kg of water are sequentially added to 13kg of mother liquor, and after stirring for 10 hours, 5.7kg of kaolin is added , 2.6kg of silica sol, 0.2kg of starch, after mixing and shearing spray molding, the spray-molded microspheres were roasted at 400°C for 6h to obtain solid microspheres. 30g of solid microspheres, 68g of diethylamine and 60g of water were added to a stainless steel reaction kettle, and the kettle was placed in a homogeneous reactor at 200°C for 48 hours of stirring and crystallization, and spherical catalyst particles were obtained after separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com