Molecular sieve film and preparation method thereof

A molecular sieve and film coating technology, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, surface pretreatment, etc., can solve the problems of not easy to scale up continuous production, heavy coating process, expensive microwave equipment, etc. Achieve the effect of being conducive to recycling, high film formation repeatability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Low-concentration coating solution primary coating film prepares AlPO on glass sheet 4 -5 molecular sieve membrane

[0031] (1) Rinse the support body with deionized water and ultrasonically remove the dirt on the surface, and dry at 28°C;

[0032] (2) Prepare Al separately 2 o 3 5% aluminum sol and H 3 PO 4 A phosphoric acid-based coating solution with a mass content of 3wt% is used for coating;

[0033](3) The first step of film coating: first immerse the glass piece in aluminum sol to coat the film, soak for 6 minutes, take out the support at a speed of 5mm / s, and dry at room temperature (28°C) for 1 hour;

[0034] (4) The second step of coating: immerse the coated aluminum sol and dried glass sheet in the phosphoric acid coating solution to coat the film, dip for 6 minutes, take out the support at a speed of 5 mm / s, Dry for 1h;

[0035] Place the dried original film on the upper part of the gas phase reactor, add a mixture of triethylamine and w...

Embodiment 2

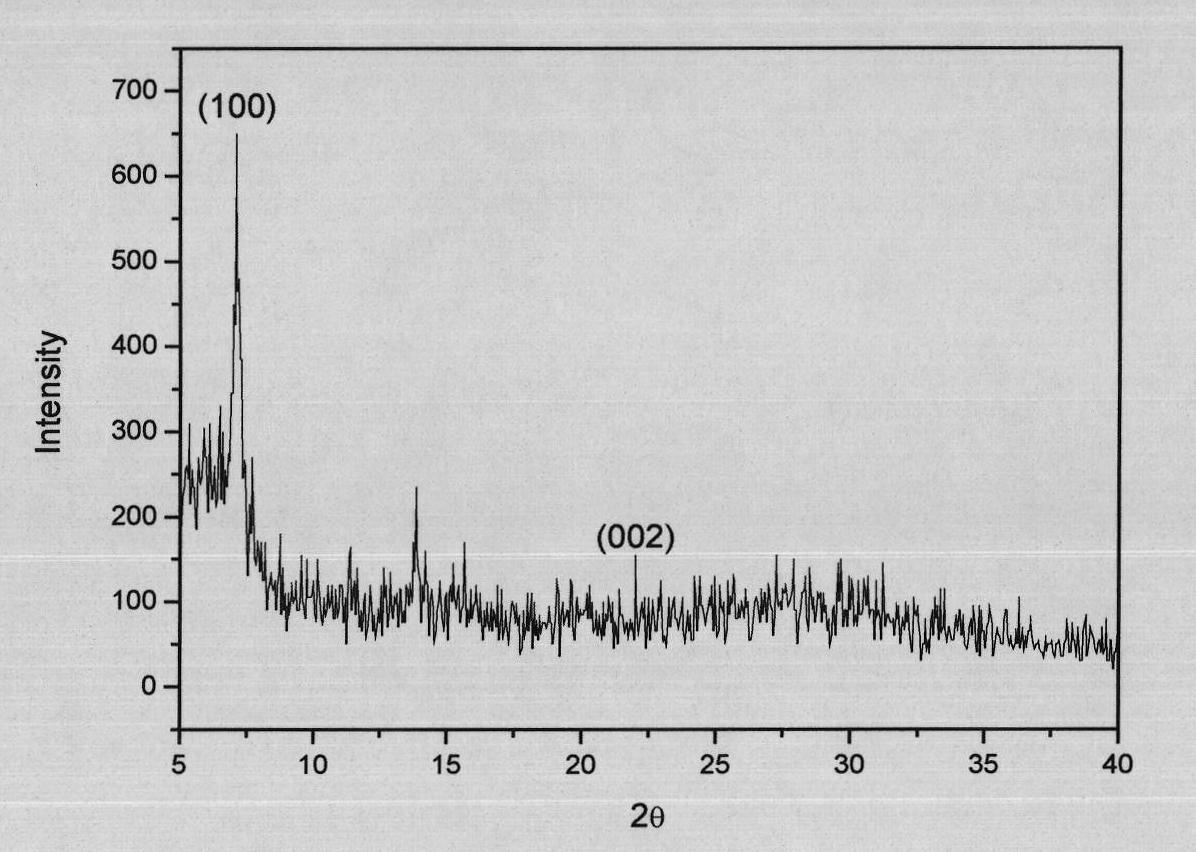

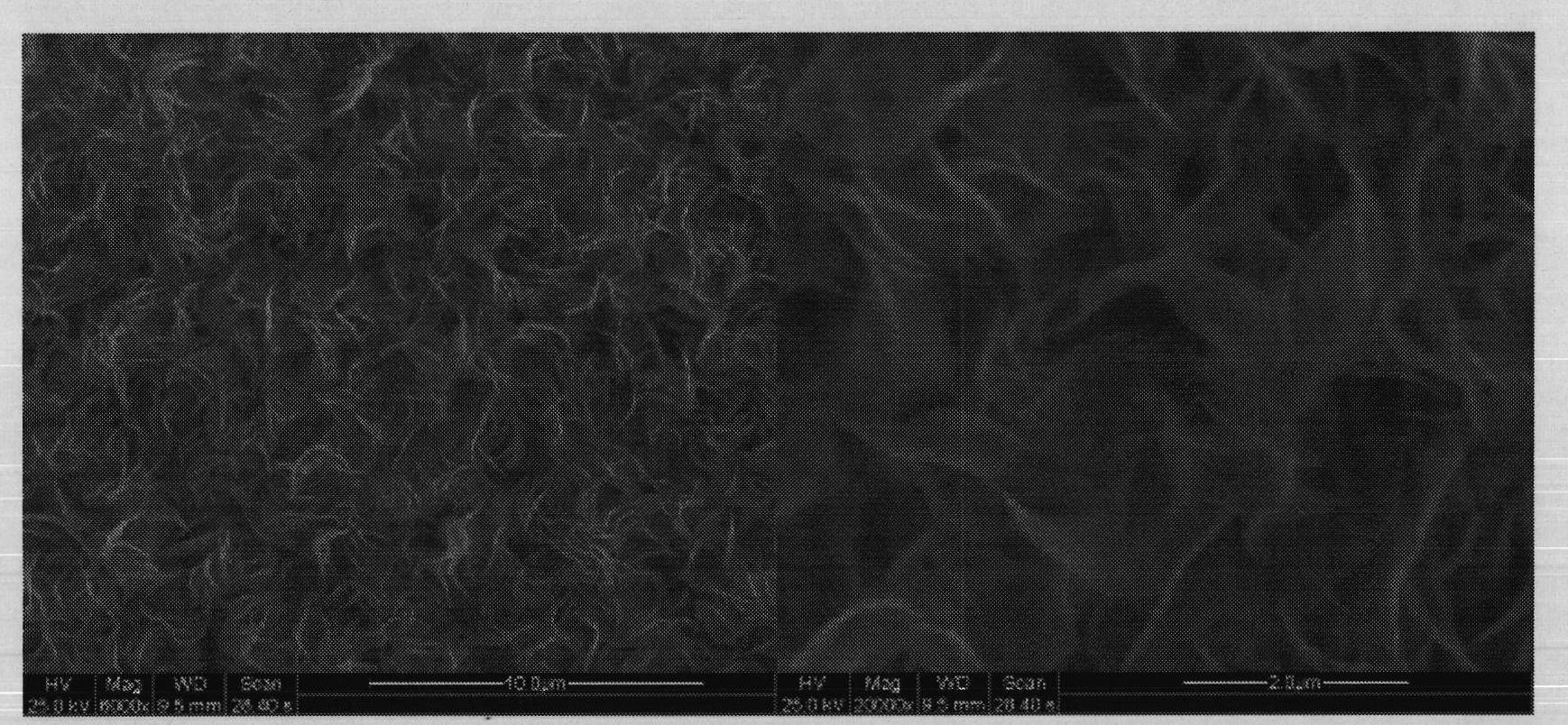

[0035] Place the dried original film on the upper part of the gas phase reactor, add a mixture of triethylamine and water with a molar ratio of 1:10 at the bottom of the reactor, the total volume of the mixture accounts for 1 / 3 of the reactor, and react at 180°C After 48 hours, the sample was rinsed with deionized water and dried at 100°C for 24 hours to obtain AlPO 4 -5 molecular sieve membrane. XRD characterization results such as figure 1 As shown, the characteristic peak representing the (100) plane is at about 7.3°, which is the most obvious characteristic peak in the entire spectrum, while the characteristic peak of the (002) plane at about 21° is very small, almost negligible, indicating that It is found that the crystal arrangement is mainly based on the (100) plane, and at the same time from the electron microscope characterization of the film ( figure 2 It can be seen that the surface of the glass sheet is covered with a layer of oriented petal-like crystals, whic...

Embodiment 3

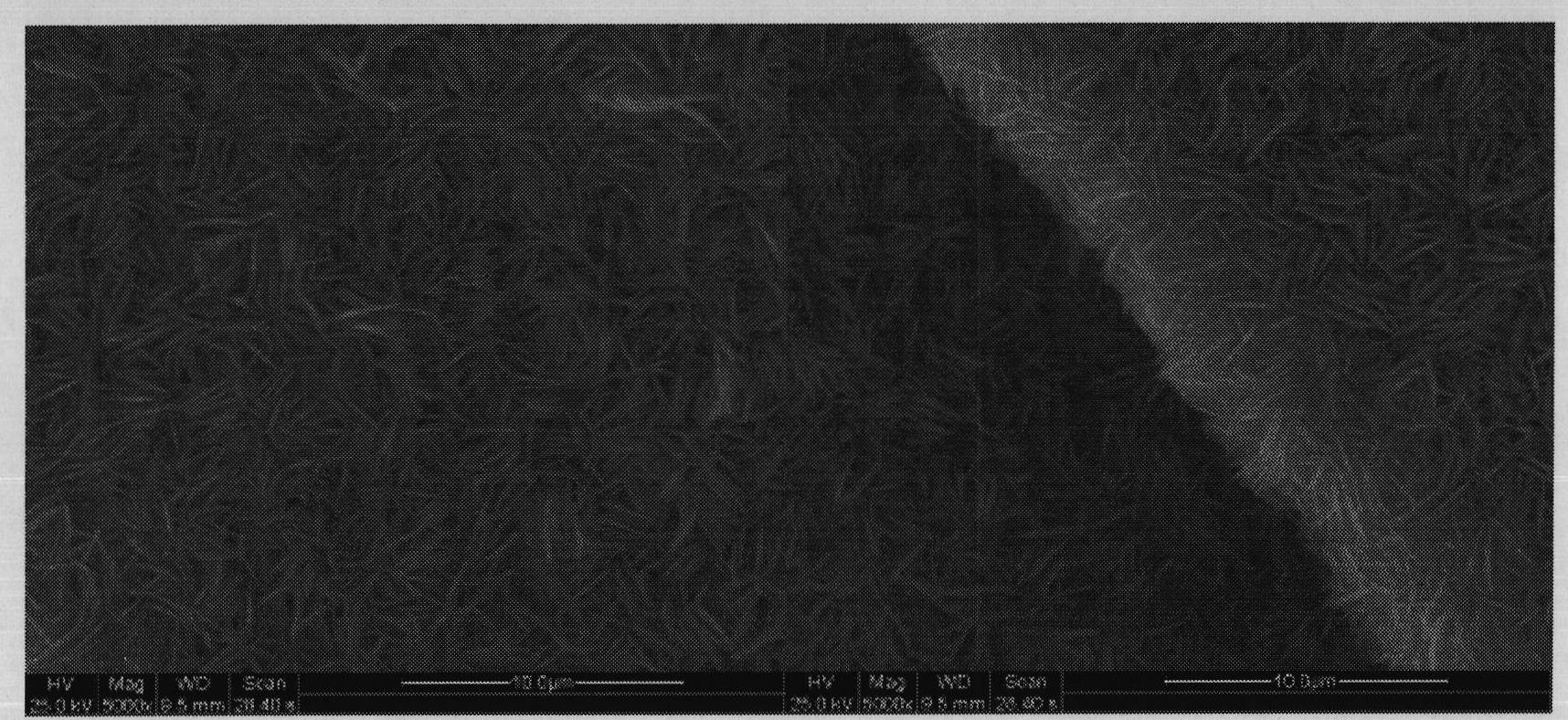

[0041] Example 3: Preparation of AlPO on a stainless steel sheet by one-time coating of high-concentration coating solution 4 -5 molecular sieve membrane

[0042] (1) Rinse the support body with deionized water and ultrasonically remove the dirt on the surface, and dry at 25°C;

[0043] (2) Prepare Al separately 2 o 3 The mass content is 20% aluminum sol and H 3 PO 4 A phosphoric acid-based coating solution with a mass content of 11% is used as the coating solution;

[0044] (3) The first step of film coating: first immerse the glass piece in the aluminum sol to coat the film, soak for 3 minutes, take out the support at a speed of 5mm / s, and dry at room temperature (25°C) for 2 hours;

[0045] (4) The second step of coating: immerse the coated aluminum sol and dried glass sheet in the phosphoric acid-based coating solution to coat the film, dip for 3 minutes, take out the support at a speed of 5 mm / s, and store it at room temperature (25°C) Dry for 2 hours;

[0046] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com