Recycling method for catalytic cracking waste catalyst

A catalytic cracking and waste catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high preparation cost and complex preparation process, and achieve simple method, low energy consumption, high activity and high performance. The effect of improved distribution of heavy oil cracking products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the present invention, the calcined kaolin microspheres refer to kaolin microspheres calcined at high temperature before in-situ crystallization when the catalytic cracking catalyst is prepared by the in-situ crystallization method, which is well known to those skilled in the art, for example, Its preparation method may include the following steps: mixing and beating kaolin, dispersant and water in sequence to obtain kaolin slurry; wherein, SiO 2The calculated weight of the dispersant is 2-4% by weight of the total weight of the kaolin on a dry basis, and the solid content of the kaolin slurry is 35-45% by weight; the kaolin slurry is spray-dried to obtain Kaolin microspheres: roasting the kaolin microspheres at 650-1000° C. for 0.5-20 hours to obtain roasted kaolin microspheres.

[0028] According to the present invention, the directing agent refers to a molecular sieve synthesis raw material with a certain amount of Y-type molecular sieve crystal nuclei, ...

Embodiment 1

[0044] This example illustrates the preparation of calcined kaolin microspheres.

[0045] Add 300g water glass in 15Kg chemical water (provided by Qilu Catalyst Company, SiO 2 262g / L, modulus 3.43, density 1260g / L) as dispersant, add 10Kg dry base kaolin (Suzhou kaolin company product, SiO 2 50.8%, Al 2 o 3 44.3%, K 2 O 0.59%, Fe 2 o 3 0.83%) beating and spray drying to obtain kaolin microspheres. Kaolin microspheres were calcined in a muffle furnace at 900° C. for 3 h to obtain calcined kaolin microspheres.

Embodiment 2

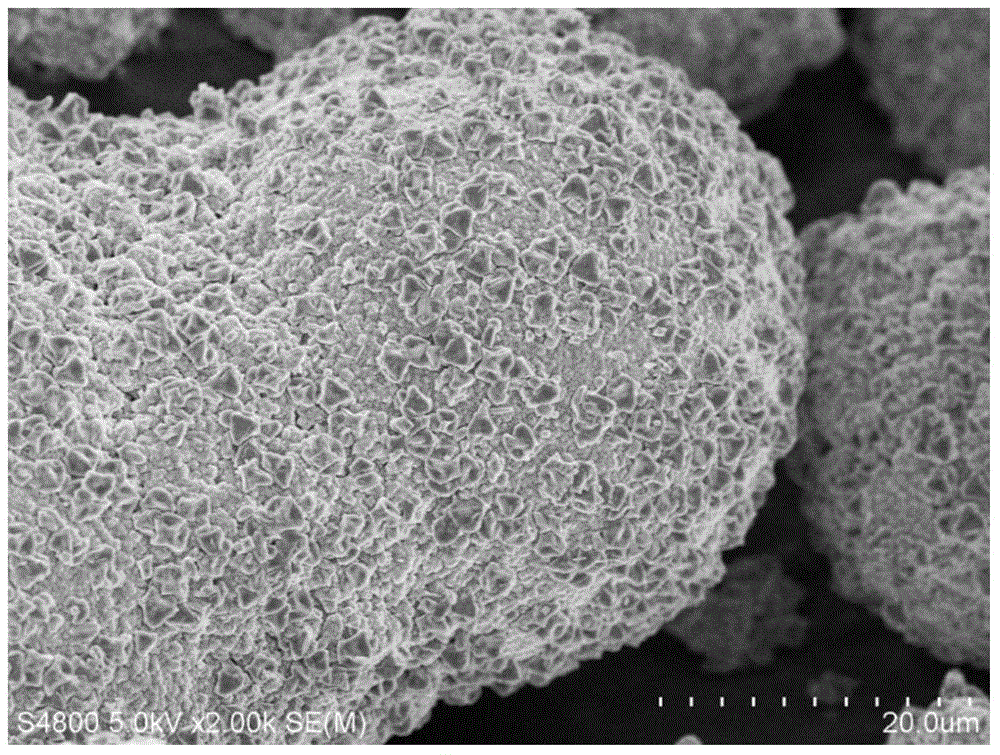

[0047] This example illustrates the preparation of the crystallized microspheres provided by the present invention.

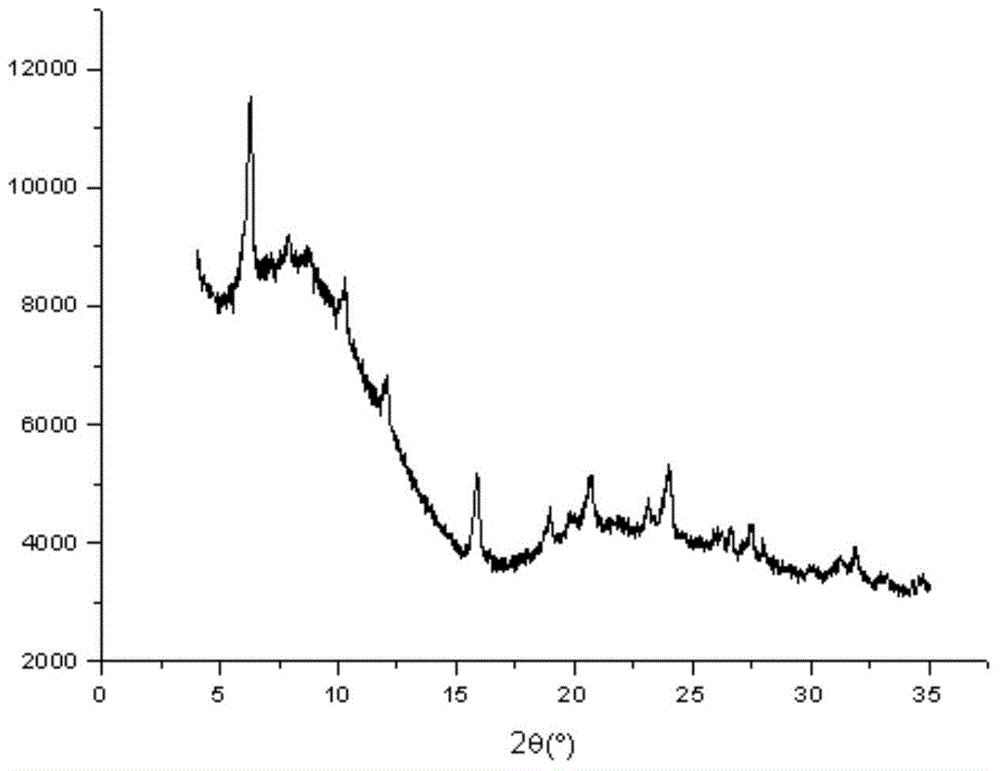

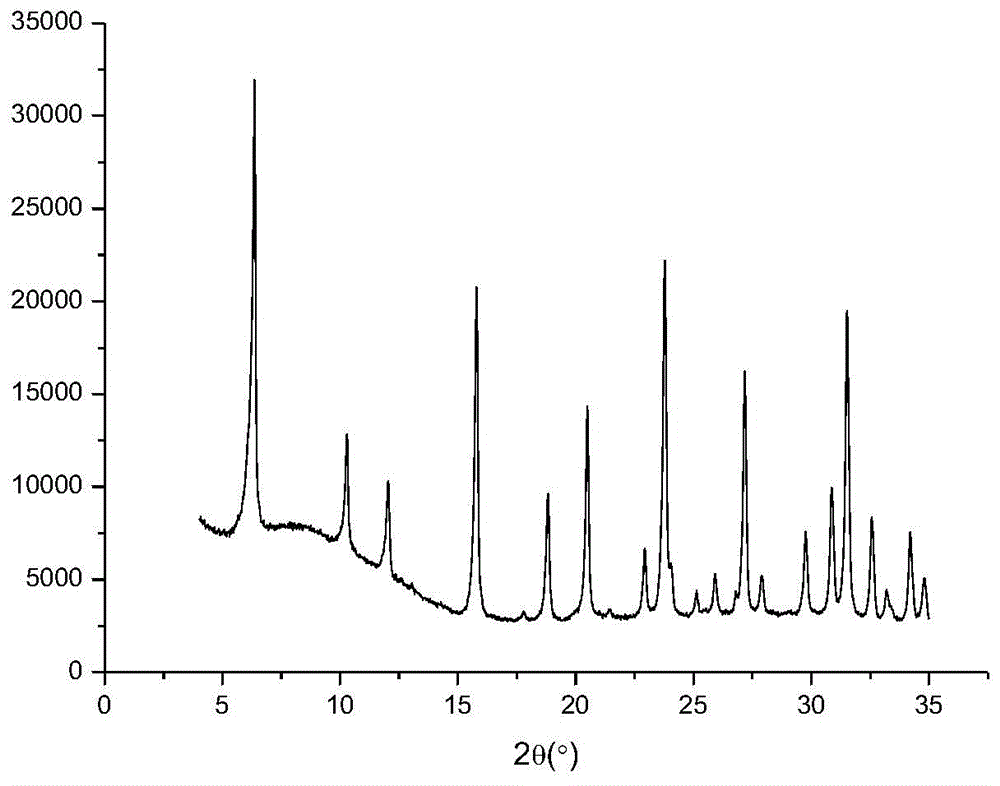

[0048] With 75g calcined kaolin microspheres and 75g catalytic cracking waste catalyst (provided by the catalytic workshop of Yanshan Petrochemical Company, denoted as YH-3: SiO 2 37.4%, Al 2 o 3 52.8%, RE 2 o 3 3.2%, Fe 0.84%, Ni1.19%, V 0.39%) and 371g water glass (Qilu Catalyst Company provides, SiO 2 262g / L, modulus 3.43, density 1260g / L), 214g directing agent and 90g water were mixed evenly in the synthesis kettle, and the temperature was raised to 98°C while stirring, and the dynamic crystallization was maintained for 26h. Then the crystallized product was unloaded, filtered, washed, and dried overnight in an oven at 120°C to obtain the crystallized microsphere provided by the present invention, denoted as KEY-B2, with a crystallinity of 33.7% and a skeleton silicon-aluminum ratio of 5.4. The XRD spectrum of catalytic cracking waste catalyst YH-3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com