Process improvement method of vulcanized hydrogenation refining catalyst

A technology for hydrorefining and process improvement, applied in the field of catalysis, can solve the problems of flammability, long process route for catalyst preparation, long vulcanization time, etc., to inhibit the generation of Mo-O-Al bonds, avoid the decrease of active surface area, and reduce the activity of the catalyst. The effect of high metal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the vulcanized hydrofining catalyst of the present invention is to impregnate the macroporous alumina powder with an impregnating solution containing active metals, and after the in-situ crystallization reaction in a closed container, add a binder and knead, after forming and drying, in an inert gas Roasting under the protection of sulfide type hydrorefining catalyst.

[0033] In the preparation process of the sulfide-type hydrofining catalyst of the present invention, the impregnation method is a conventional method in the field, and the required metal salt, vulcanizing agent, organic complexing agent and dispersant are mixed, stirred and dissolved, and prepared into a clarified product with a suitable pH value. solution, and then impregnated by means of saturated impregnation or excess impregnation.

[0034] The specific preparation method of sulfurized hydrorefining catalyst of the present invention is as follows:

[0035] 1. Configuration ...

Embodiment 1

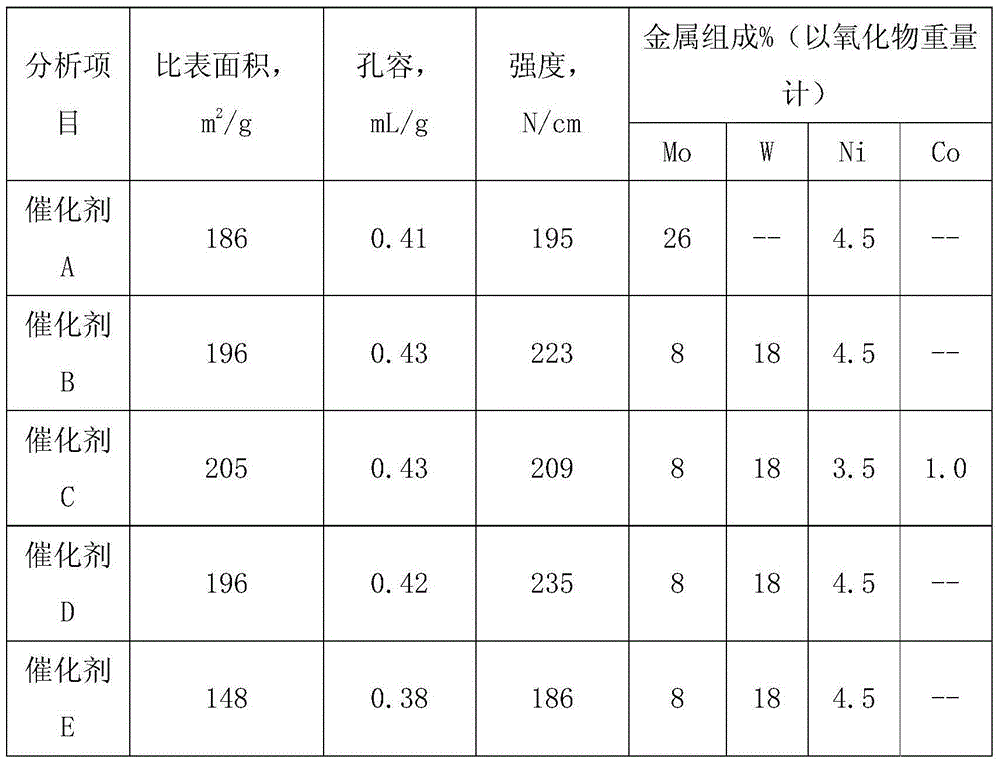

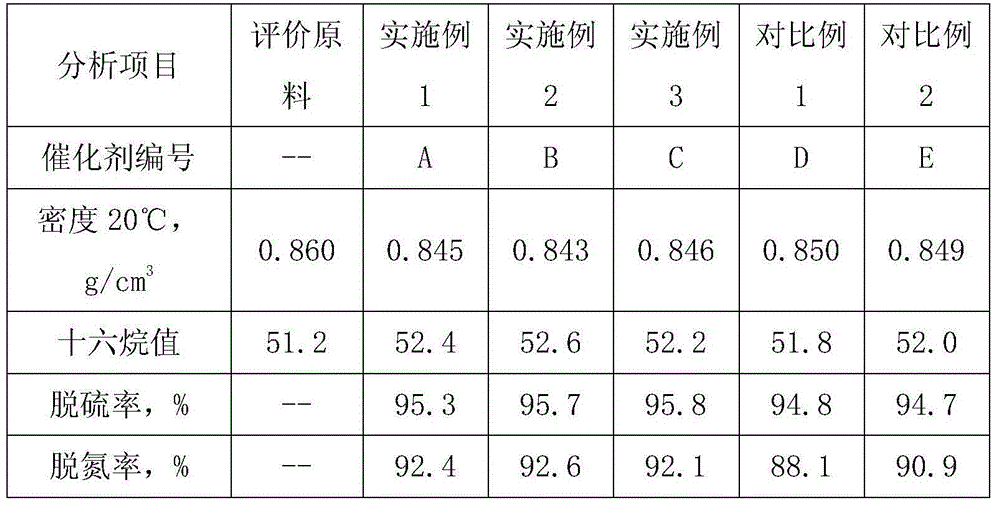

[0038] The preparation of embodiment 1 sulfurized catalyst A

[0039] Dissolve nickel nitrate, ammonium molybdate and aminotriacetic acid in water to obtain a transparent solution, add polyethylene glycol-400 and thioacetamide in turn, mix and stir to dissolve to form a clear solution, the concentration of polyethylene glycol-400 in the solution The concentration of nickel and molybdenum (calculated as oxide) is 4.5 and 26.0g / 100ml respectively.

[0040] Take 100ml of the mixed solution and spray and soak 100g of macroporous alumina powder (macroporous pseudo-boehmite produced by Shandong Aluminum Company, 68% by weight on a dry basis), in-situ crystallization reaction at 75°C in a closed reaction kettle After 5h, dry in air to loose powder; then add 20g aluminum sol (solid content is 30% by weight), knead in kneader for 30min, then extrude into 1.5mm clover strips on extruder, 130 ℃ air Dry in medium for 8 hours, and finally bake at 480°C for 3 hours under the protection of ...

Embodiment 2

[0041] The preparation of embodiment 2 sulfurized catalyst B

[0042] Dissolve nickel nitrate, ammonium molybdate, ammonium tungstate and amino trimethylene phosphonic acid in water to obtain a transparent solution, add fatty acid polyoxyethylene ester and ammonium thiosulfate in sequence, mix and stir to dissolve to form a clear solution, and the fatty acid polyoxyethylene in the solution The concentration of oxyethylene ester was 2.8g / 100ml, and the concentrations of nickel, molybdenum and tungsten (calculated as oxides) were 4.5, 8 and 18.0g / 100ml, respectively.

[0043] Take 100ml of the mixed solution and spray and soak 100g of macroporous alumina powder (macroporous pseudo-boehmite produced by Shandong Aluminum Company, 68% by weight on a dry basis), in-situ crystallization reaction at 50°C in a closed reaction kettle After 6h, dry in air to loose powder; then add 10g aluminum sol and 10g silica sol (solid content is 30% by weight), knead in kneader for 30min, then extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com