ZSM-5/rectorite composite catalytic material and preparation method thereof

A technology of ZSM-5 and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as different process conditions, achieve reduced preparation costs, good hydrothermal stability, and improved The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add water and binder (silica sol) to the commercially available rectorite to extrude into strips, dry the strips and crush them into rectorite particles with a particle size of 80-110 μm, roast at 1000°C for 1 hour, and set aside.

[0044] Water glass (containing SiO 2 26wt%, Na 2 O 8wt%) 16g, TPABr 1.6g, distilled water 114g, concentration is the sulfuric acid aqueous solution 5g of 3M, and the rectorite particle 6g after the above-mentioned roasting process mixes, and stirs about 1h (this moment, reactant gel pH value is about 8 ). Each component in the gel is calculated as (Na 2 O+K 2 O) / SiO 2 =0.3, TPABr / SiO 2 =0.09,H 2 O / SiO 2 =100.

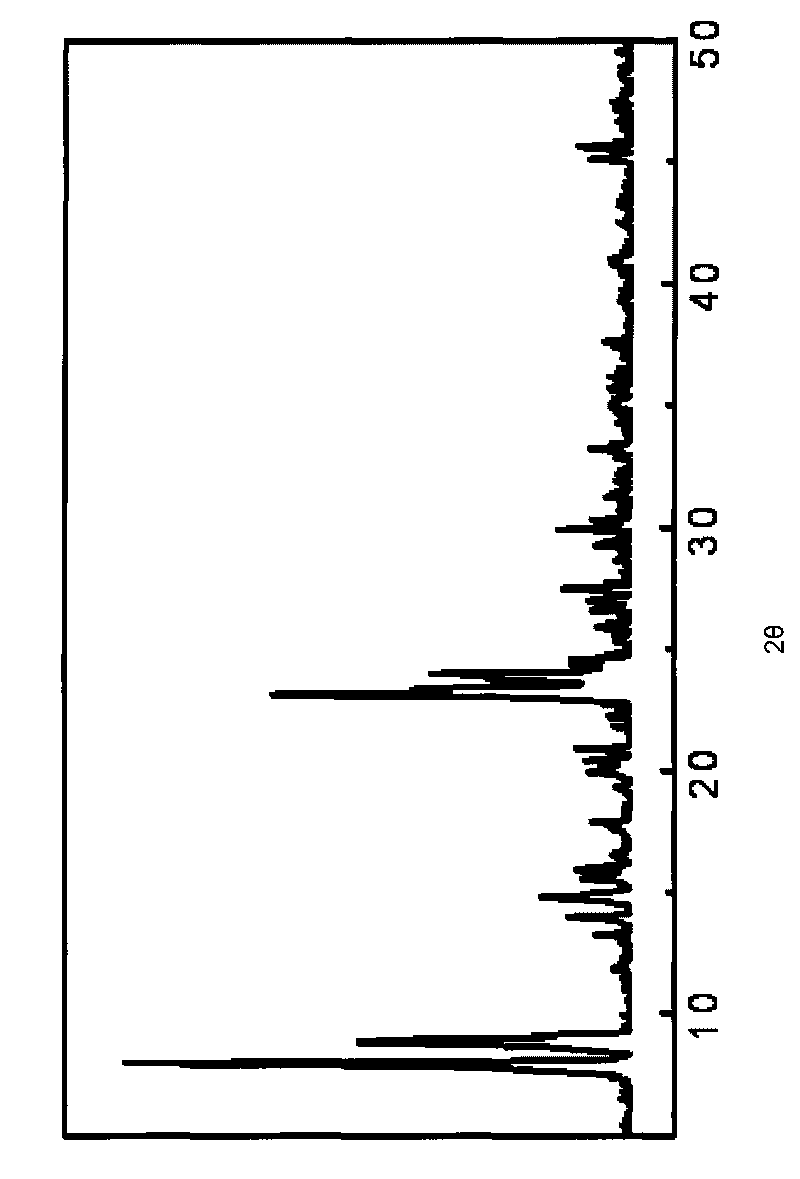

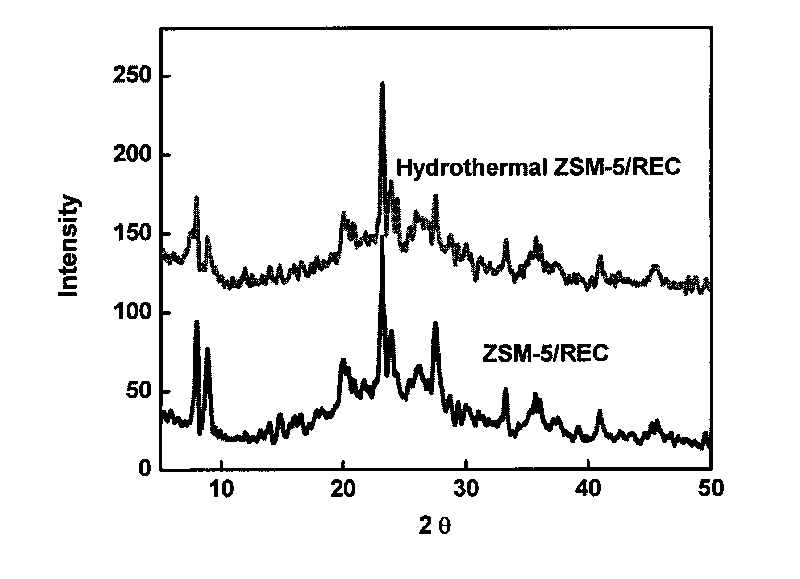

[0045] The mixed gel was poured into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 170°C for static crystallization for 72 hours. After the crystallization is completed, cool and filter to remove the mother liquor, wash, dry, and roast at 550° C. to remove the template agent to obtain...

Embodiment 2

[0047] Add water and binder (silica sol) to the commercially available rectorite to extrude into strips, dry the strips and crush them into rectorite particles with a particle size of 50-100 μm, roast at 1050°C for 1 hour, and set aside.

[0048] Water glass (containing SiO 2 26wt%, Na 2 O 8wt%) 20g, TPABr 1.6g, distilled water 112g, concentration is that the sulfuric acid aqueous solution 3g of 3M and the rectorite particle 6g after roasting process mix, and stir about 1h (at this moment, reactant gel pH value is about 9), Each component in the gel is calculated as (Na 2 O+K 2 O) / SiO 2 =0.3, TPABr / SiO 2 =0.07,H 2 O / SiO 2 =80.

[0049] The mixed gel was poured into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 170°C for static crystallization for 48 hours. After the crystallization is completed, cool and filter to remove the mother liquor, wash, dry, and roast at 550° C. to remove the template agent to obtain a crystallized prod...

Embodiment 3

[0051] Add water and binder (water glass) to the commercially available rectorite to extrude into strips, dry the strips and crush them into rectorite particles with a particle size of 80-130 μm, roast at 1100°C for 1 hour, and set aside.

[0052] Water glass (containing SiO 2 26wt%, Na 2 O 8wt%) 8g, TPABr 0.55g, distilled water 69g, concentration is that the rectorite particle 6g after the sulfuric acid aqueous solution 3g of 3M and roasting process mixes, and stirs 1h (at this moment, reactant gel pH value is about 10), coagulation Each component in the glue is calculated as (Na 2 O+K 2 O) / SiO 2 =0.3, TPABr / SiO 2 =0.06,H 2 O / SiO 2 =120.

[0053] The mixed gel was poured into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 155°C for static crystallization for 72 hours. After the crystallization is completed, cool and filter to remove the mother liquor, wash, dry, and roast at 550° C. to remove the template agent to obtain a crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com