Chitosan-hydroxylapatite in-situ loaded icariin composite microspheres

A technology of hydroxyapatite and icariin, which is applied in the field of biomedical materials, can solve the problems of unprepared microspheres and the like, and achieve the effects of promoting wound healing, convenient operation and promoting bone formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

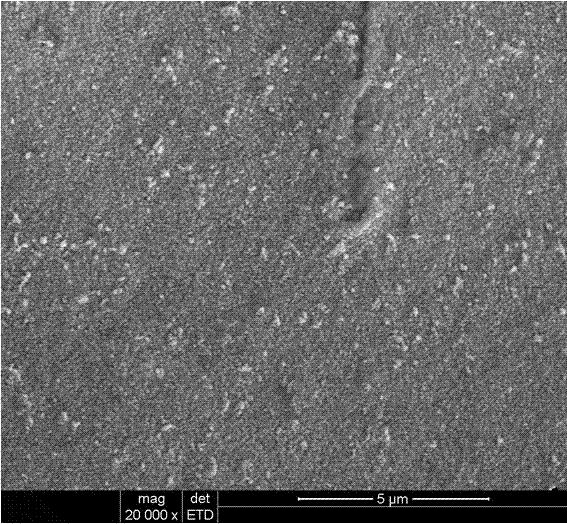

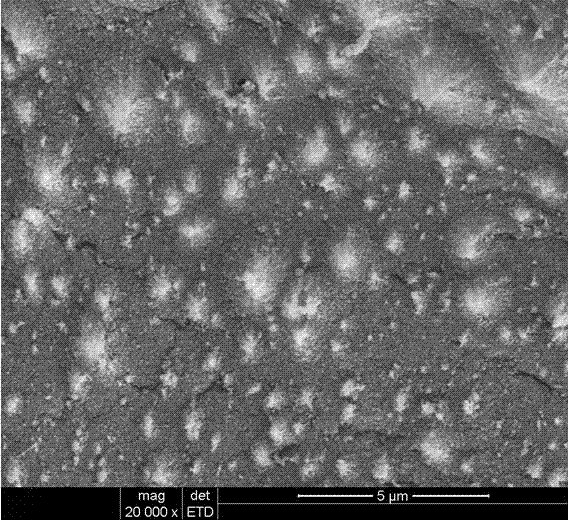

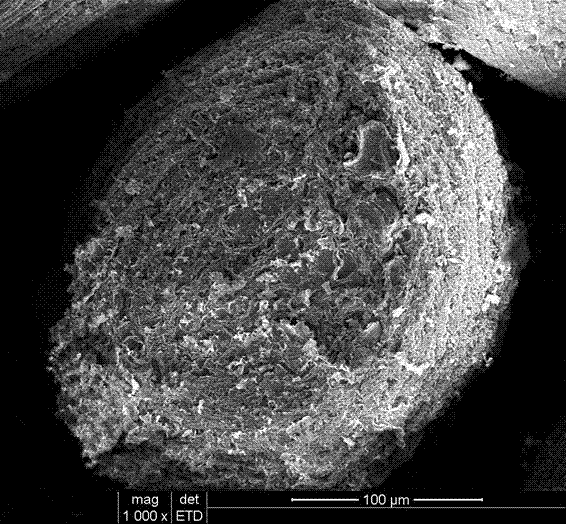

Image

Examples

Embodiment 1

[0034]1) Prepare 1.5mol / L soluble calcium salt solution and 1.8mol / L soluble phosphate solution; the contents of chitosan and icariin are respectively 2% and 0.01% by mass percentage;

[0035] 2) dissolving the chitosan in the ratio in 1% acetic acid solution, and dissolving the icariin in the ratio in absolute ethanol;

[0036] 3) According to n(Ca 2+ ):n(PO 4 3- )=1.67:1 ratio, a certain amount of soluble calcium salt solution and soluble phosphate solution were added to the above-mentioned mixed solution respectively, continuously stirred for 2 h, and the mass ratio of theoretically forming HAP was 1%;

[0037] 4) Slowly add the icariin alcohol solution to the above solution, stir to make it fully mixed;

[0038] 5) Put the above mixed solution through a microcapsule forming device, drop it into a 3% NaOH aqueous solution to form it, put it together with the gel bath in a 37°C water bath for 8 hours, carry out in-situ crystallization, and then repeatedly soak it with dei...

Embodiment 2

[0040] 1) Prepare 2mol / L soluble calcium salt solution and 1.2mol / L soluble phosphate solution; the contents of chitosan and icariin are respectively 1% and 0.03% by mass percentage;

[0041] 2) dissolving the chitosan in the ratio in 1% acetic acid solution, and dissolving the icariin in the ratio in absolute ethanol;

[0042] 3) According to n(Ca 2+ ):n(PO 4 3- )=1.67:1 A certain amount of soluble calcium salt solution and soluble phosphate solution were added to the above mixture respectively, and stirred continuously for 3 h, the theoretical mass ratio of forming HAP was 0.5%.

[0043] 4) Slowly add the icariin alcohol solution to the above solution, stir to make it fully mixed;

[0044] 5) Pass the above mixed solution through a microcapsule forming device, drop it into a 3% NaOH aqueous solution to form it, and place it together with the gel bath in a 37°C water bath for 10 hours for in-situ crystallization, and then repeatedly soak it with deionized water until Neut...

Embodiment 3

[0046] 1) Prepare 3mol / L soluble calcium salt solution and 0.6mol / L soluble phosphate solution; the contents of chitosan and icariin are respectively 2% and 0.05% by mass percentage;

[0047] 2) dissolving the chitosan in the ratio in 1% acetic acid solution, and dissolving the icariin in the ratio in absolute ethanol;

[0048] 3) According to n(Ca 2+ ):n(PO 4 3- )=1.67:1 ratio, a certain amount of soluble calcium salt solution and soluble phosphate solution were added to the above-mentioned mixed solution respectively, continuously stirred for 4 h, and the mass ratio of theoretically forming HAP was 0.8%;

[0049] 4) Slowly add the icariin alcohol solution to the above solution, stir to make it fully mixed;

[0050] 5) Put the above mixed solution through a microcapsule forming device, drop it into a 4% NaOH aqueous solution to form it, and place it together with the gel bath in a 37°C water bath for 8 hours for in-situ crystallization, and then repeatedly soak it with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com