Composite photocatalyst and preparation method thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problems of low catalytic efficiency, complex synthesis process, high energy consumption, etc., and achieve the effects of high catalytic efficiency, simple process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

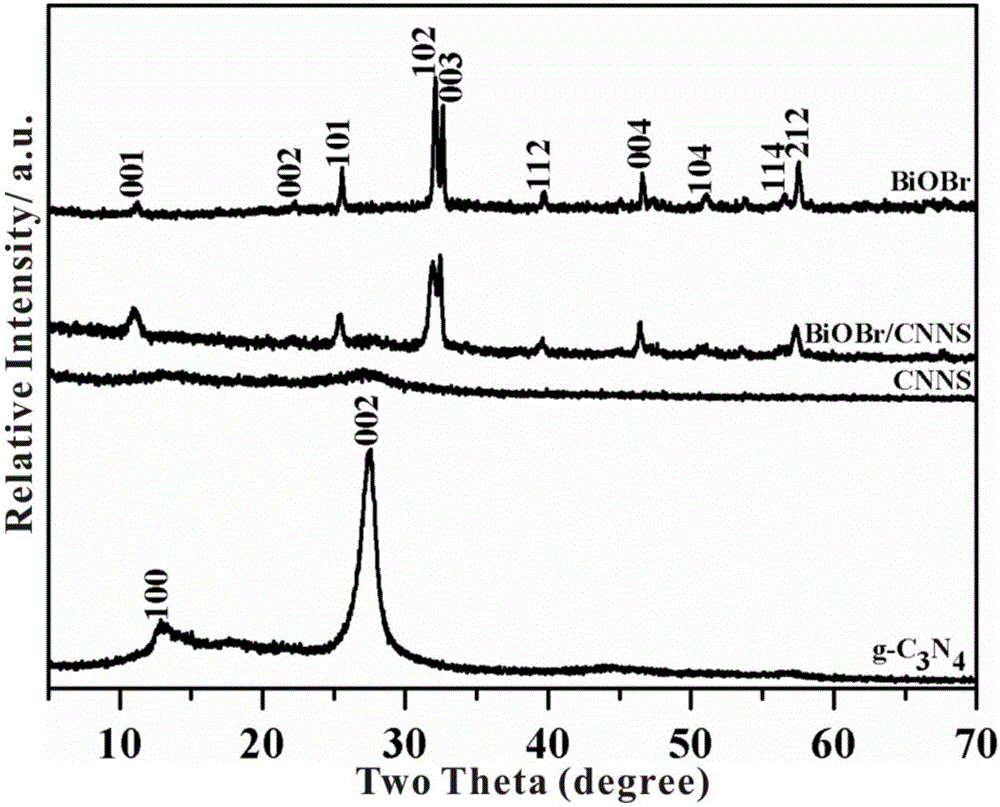

[0022] A kind of preparation method of composite photocatalyst provided by the embodiment of the present invention comprises the following steps:

[0023] S1. Calcining urea to obtain CNNS to be treated.

[0024] Furthermore, the calcination process of urea is to place the urea on a semi-closed carrier, and then place it in a furnace protected by an inert gas for calcination at a temperature of 550-555°C, and the calcination time is 3.8-4 hours. The heating rate of the calcination process is 2-2.2° C. / min. It should be noted that, according to the high temperature requirements of the experiment process, during the calcination process, the carrier is preferably a crucible with a crucible cover, and the furnace used for calcination can be a commonly used tube furnace.

[0025] S2. Carrying out first washing and first drying sequentially on the CNNS to be processed obtained in step S1 to obtain CNNS.

[0026] It should be noted that the first washing process is specifically to ...

Embodiment 1

[0033] This embodiment provides a kind of preparation method of composite photocatalyst, and its preparation process is as follows:

[0034] Weigh 7.5 grams of urea, put it in a crucible, and put a crucible lid on the crucible to make it in a semi-closed state. Then, place it in a tube furnace as a whole for calcination at 550 ° C. The calcination time is 4 During the calcination process, argon gas was introduced for gas protection, and the heating rate during the calcination process was 2° C. / min.

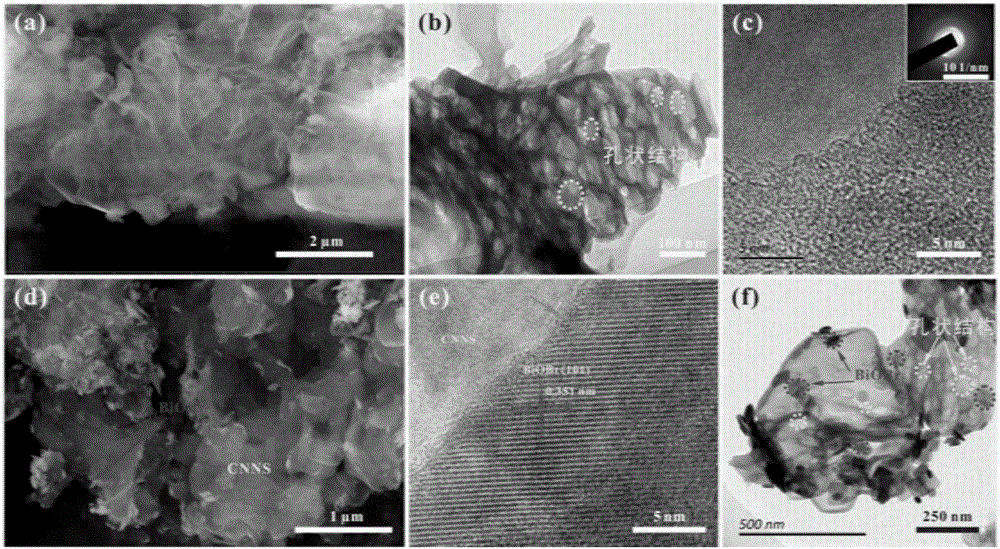

[0035] After calcination, the obtained samples were washed once with absolute ethanol and three times with deionized water, and the washed samples were vacuum-dried at 60°C in a vacuum oven to obtain CNNS with a porous structure.

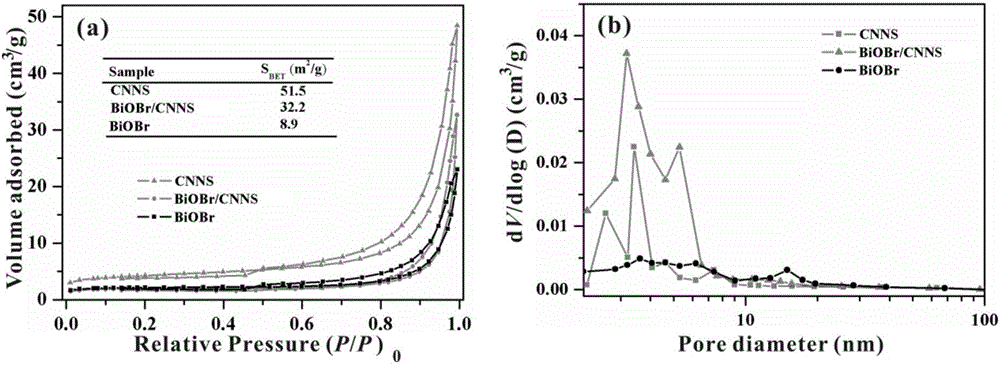

[0036] 0.32 g of Bi(NO 3 ) 3 ·5H 2 O and 0.08 g of KBr were dispersed in ethylene glycol to form a BiOBr precursor solution; 0.8 g of CNNS was dispersed in 80 mL of deionized water and sonicated for 30 minutes to form g-C 3 N 4 Nanosheet suspension...

Embodiment 2

[0040] This embodiment provides a kind of preparation method of composite photocatalyst, and its preparation process is as follows:

[0041] Weigh 7.5 grams of urea, put it in a crucible, and put a crucible lid on the crucible to make it in a semi-closed state. Then, place it in a tube furnace as a whole for calcination at 555 ° C. The calcination time is 3.8 During the calcination process, argon gas was introduced for gas protection, and the temperature rise rate during the calcination process was 2.2° C. / min.

[0042] After calcination, the obtained sample was washed once with absolute ethanol and three times with deionized water, and the washed sample was vacuum-dried at 62°C in a vacuum oven to obtain CNNS with a porous structure.

[0043] 0.32 g of Bi(NO 3 ) 3 ·5H 2 O and 0.08 g of KBr were dispersed in ethylene glycol to form a BiOBr precursor solution; 0.88 g of CNNS was dispersed in 80 mL of deionized water and sonicated for 30 minutes to form g-C 3 N 4 Nanosheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com