Hydrotalcite-like compound/eggshell membrane composite film and preparation method thereof

A technology of composite film and eggshell membrane, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., to achieve cost saving, good removal of hexavalent chromium, and environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A. Soak fresh eggshells in HCl solution with a concentration of 2M. After the calcium carbonate in the eggshells is dissolved, separate the eggshell membranes and wash them for later use;

[0038] B. Weigh 1.71gMg(NO 3 ) 2 ·6H 2 O, 1.25gAl(NO 3 ) 3 9H 2 O and 5.6g urea, dissolved in deionized water to configure a metal ion concentration of 0.1mol / L, Mg 2+ with Al 3+ The molar ratio is 2, urea and NO 3 - A 100mL mixed solution with a molar ratio of 4;

[0039] C. Put the eggshell membrane prepared in step A into the solution in step B, react at 90°C for 72 hours, take out the membrane, rinse it with deionized water, and dry it at room temperature to obtain CO 3 2- A composite film of hydrotalcite-like / eggshell membrane, wherein the chemical formula of the hydrotalcite-like part is Mg 0.67 Al 0.33 (OH) 2 (CO 3 ) 0.165 0.7H 2 O.

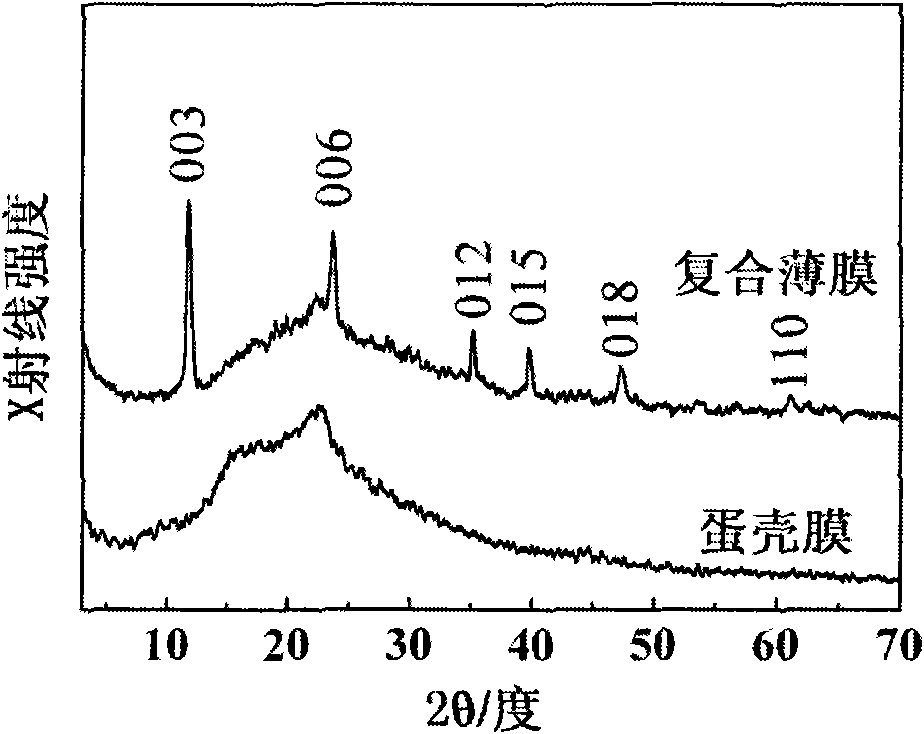

[0040] figure 1 is the CO obtained in step C 3 2- XRD diffraction patterns of hydrotalcite-like / eggshell membrane composite ...

Embodiment 2

[0043] A. Soak fresh eggshells in HCl solution with a concentration of 1M. After the calcium carbonate in the eggshells is dissolved, separate the eggshell membranes and wash them for later use;

[0044] B. Weigh 2.56gMg(NO 3 ) 2 ·6H 2 O, 1.87gAl(NO 3 ) 3 9H 2 O and 6.9g urea, dissolved in deionized water to configure a metal ion concentration of 0.15mol / L, Mg 2+ with Al 3+ The molar ratio is 2, urea and NO 3 - A 100mL mixed solution with a molar ratio of 4;

[0045] C. Place the eggshell membrane prepared in step A into the solution in step B, react at 80°C for 48 hours, take out the membrane, rinse it with deionized water, and dry it at room temperature to obtain CO 3 2- A composite film of hydrotalcite-like / eggshell membrane, wherein the chemical formula of the hydrotalcite-like part is Mg 0.65 Al 0.35 (OH) 2 (CO 3 ) 0.175 0.63H 2 O.

Embodiment 3

[0047] A. Soak fresh eggshells in HCl solution with a concentration of 3M. After the calcium carbonate in the eggshells is dissolved, separate the eggshell membranes and wash them for later use;

[0048] B. Weigh 7.12gMgCl respectively 2 , 3.33gAlCl 3 and 54.05g urea, configured so that the metal ion concentration is 1mol / L, Mg 2+ with Al 3+ The molar ratio is 3, urea and Cl - A 100mL mixed solution with a molar ratio of 4;

[0049] C. Put the eggshell membrane prepared in step A into the solution in step B, react at 90°C for 24 hours, take out the film, rinse it with deionized water, and dry it at room temperature to obtain CO 3 2- A composite film of hydrotalcite-like / eggshell membrane, wherein the chemical formula of the hydrotalcite-like part is Mg 0.75 Al 0.25 (OH) 2 (CO 3 ) 0.125 0.75H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com