Method for preparing in-situ crystallization type catalytic cracking catalyst

An in-situ crystallization and catalytic cracking technology, used in catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., can solve the problems of low ammonium salt usage and pollution, improve reaction performance and alleviate ammonia nitrogen pollution problems, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

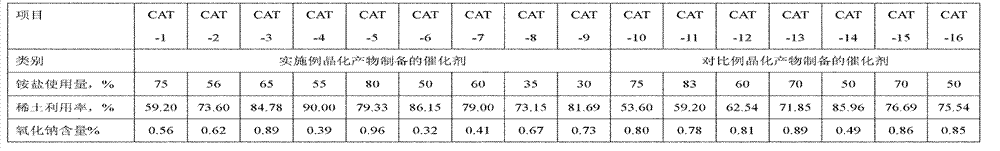

[0053] (1) Preparation of crystallized products

[0054] Examples 1 to 9 and Comparative Examples 1 to 6 are preparations of in-situ crystallization products.

Embodiment 1

[0056] With 3000g of kaolin, based on the mass of kaolin, add 10% of water glass, 6% of pseudoboehmite, 1% of auxiliary agent polydimethyldiallylammonium chloride, and add deionized water to prepare a solid content of 33%. The mixed slurry obtains the kaolin spray microspheres of 3028g. A part of the microspheres was calcined at 700° C. for 1.5 hours to obtain partial earth microspheres PT-1.

[0057] Mix 100g of PT-1 partial earth microspheres with 1321ml of water glass, 470ml of 14wt% sodium hydroxide solution, and 138ml of directing agent. After stirring for 30 minutes, the mixed solution is put into a stainless steel reaction kettle and heated to 106°C for 12 hours of static crystallization. After the crystallization is completed, the white powder in the solution is removed by settling and washing, and then the filter cake is filtered, washed, and dried to obtain an in-situ crystallization product. As determined by X-ray diffraction, it contains 51% NaY zeolite, and the s...

Embodiment 2

[0059] With 3000g of kaolin, based on the mass of kaolin, add 6% of water glass, 4% of pseudoboehmite, 2% of auxiliary agent polydimethyldiallyl ammonium chloride, and add deionized water to prepare a solid content of 37%. The mixed slurry obtains the kaolin spray microspheres of 3110g. A part of the microspheres was calcined at 970° C. for 1.5 hours to obtain high soil microspheres GT-2, and the other part was calcined at 800° C. for 2 hours to obtain partial earth microspheres PT-2.

[0060] Take Gaotu microsphere GT-260g and 40g partial earth microsphere PT-2, mix it with 950ml water glass, 316ml14wt% sodium hydroxide solution, and 134ml guiding agent, stir for 30 minutes, and then put the mixture into a stainless steel reaction kettle , the temperature was raised to 96°C for static crystallization at a constant temperature for 26 hours. After the crystallization is completed, the white powder in the solution is removed by settling and washing, and then the filter cake is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com