Patents

Literature

148results about How to "Intensity is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant covering yarn fabric and application thereof

InactiveCN102181993AAchieving Flame RetardancyRealize high-strength functionsWoven fabricsYarnPolyesterYarn

The invention discloses a flame-retardant covering yarn fabric and application thereof. The product is made from covering yarns, wherein the covering yarns are subjected to the processing of flame-retardant after finishing; the core yarns of the covering yarns are polyester, nylon, spandex, vinylon, polyethylene or composite yarns thereof; and the cladding material of the covering yarns are cotton fibers, viscose fibers or composite fiber materials thereof. The flame-retardant covering yarn fabric can be applied to the manufacturing of protective clothing, military clothing or military coverlets. The flame-retardant covering yarn fabric provided by the invention can keep higher physical mechanical strength and has a flame-retardant effect.

Owner:JIANGSU TANGWEAR IND

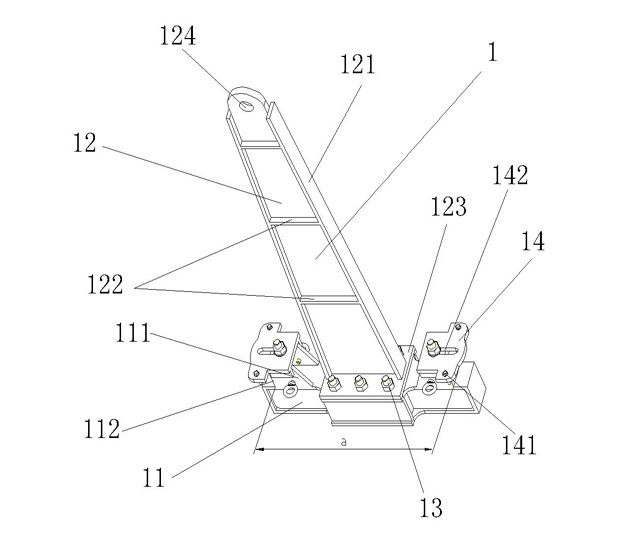

Special hanger with guide cover wheel hub and turning and hanging method

InactiveCN101966965ASmall form factorSimple structureWind energy generationLoad-engaging elementsEngineeringMechanical engineering

Owner:JIANGSU WENDE NEW ENERGY

Wood protective agent

InactiveCN1727142AAnti-leakageExcellent flame retardant functionWood impregnation detailsWater softeningAlcohol

Owner:BEIJING SHUANGCHENGMU TECH

Ultrawhite ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and preparation process thereof

ActiveCN101962819AIntensity is not affectedModulus is not affectedArtificial filament heat treatmentWet spinning methodsFiberPolymer science

The invention relates to ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and a manufacturing method thereof, in particular to ultrawhite ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and a preparation process thereof, which are applicable in fields of various protective textiles with an ultrawhite color requirement. In the invention, ultrahigh-molecular weight polyethylene is used as a raw material and is mixed with white oil to form a mixture, a diphenylethyl dibenzimidazole compound is added into the mixture as an additive to form spinning solution, and the ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers are obtained by a spinning process, wherein the amount of the additive is 0.01 to 0.05 percent based on the weight of the ultrahigh-molecular weight polyethylene. The preparation process comprises the following steps: preparing the spinning solution; performing gel spinning; balancing semi-finished product gel spinning; extracting; displacing; drying; and hot high drafting. The fibers are ultrawhite and brighter and can meet requirement for differentiation; meanwhile, the biological indexes such as strength and modulus of the finished fibers are not affected, the manufacturing method is simple, and the production cost is low.

Owner:长青藤高性能纤维材料有限公司

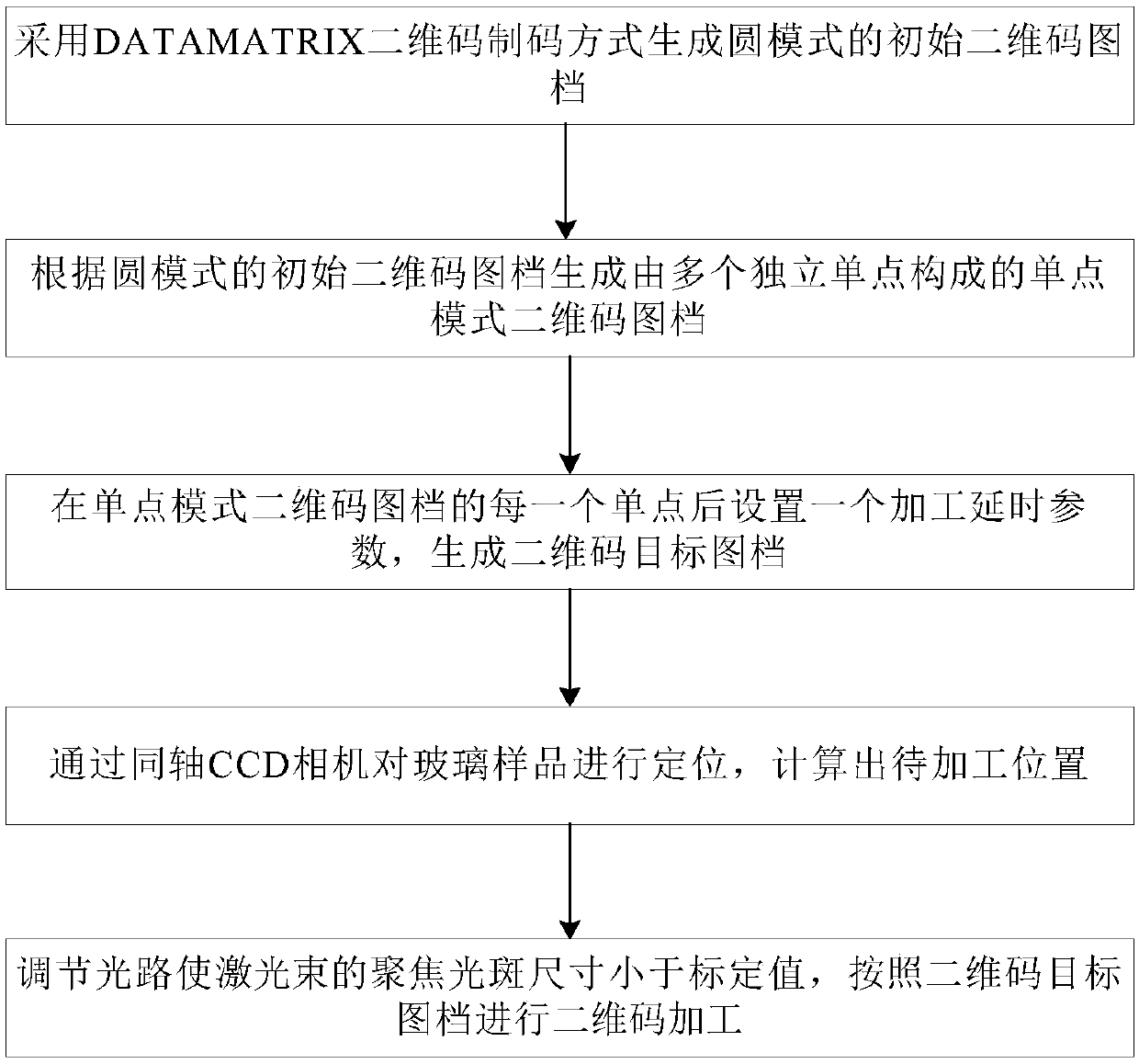

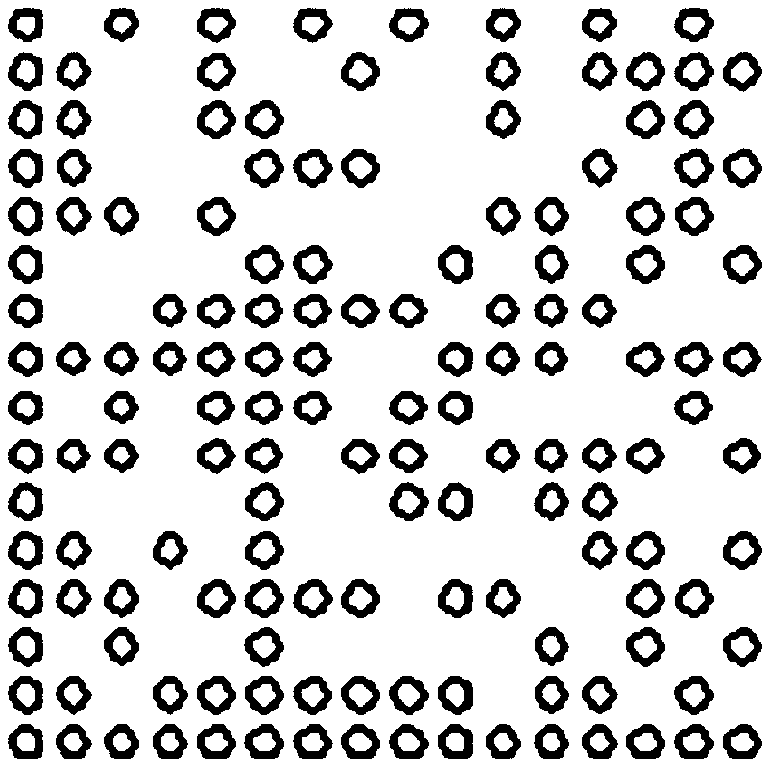

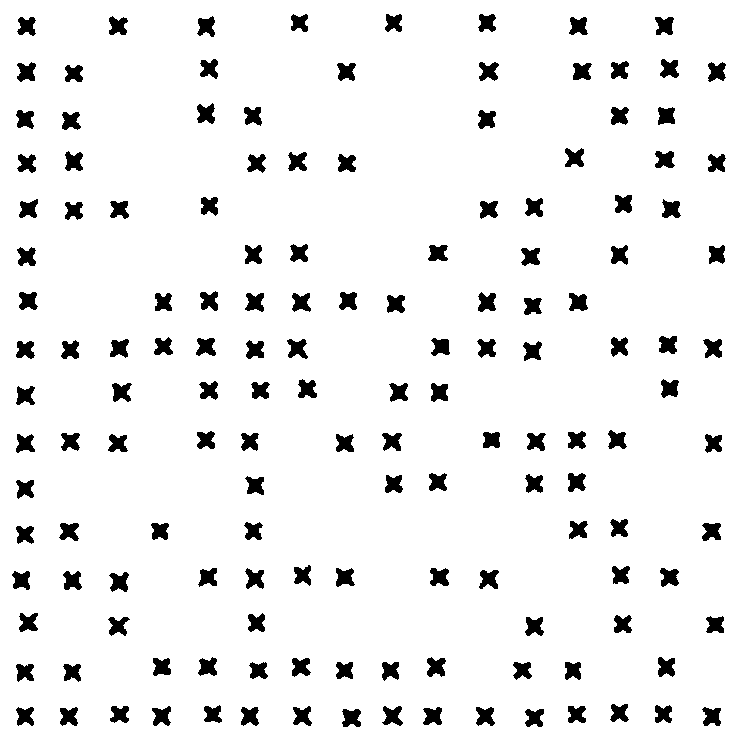

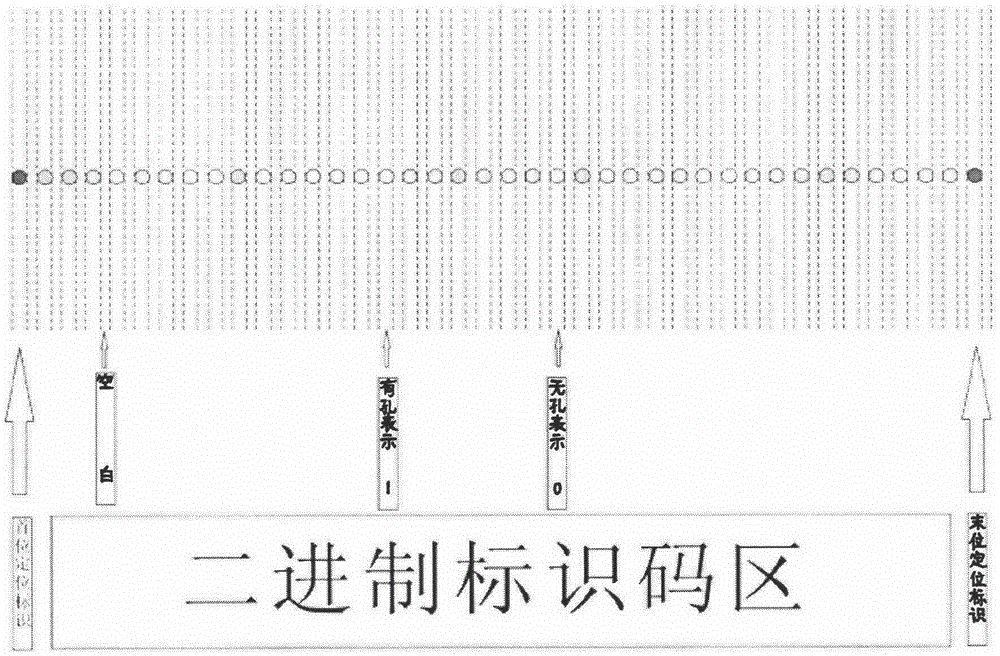

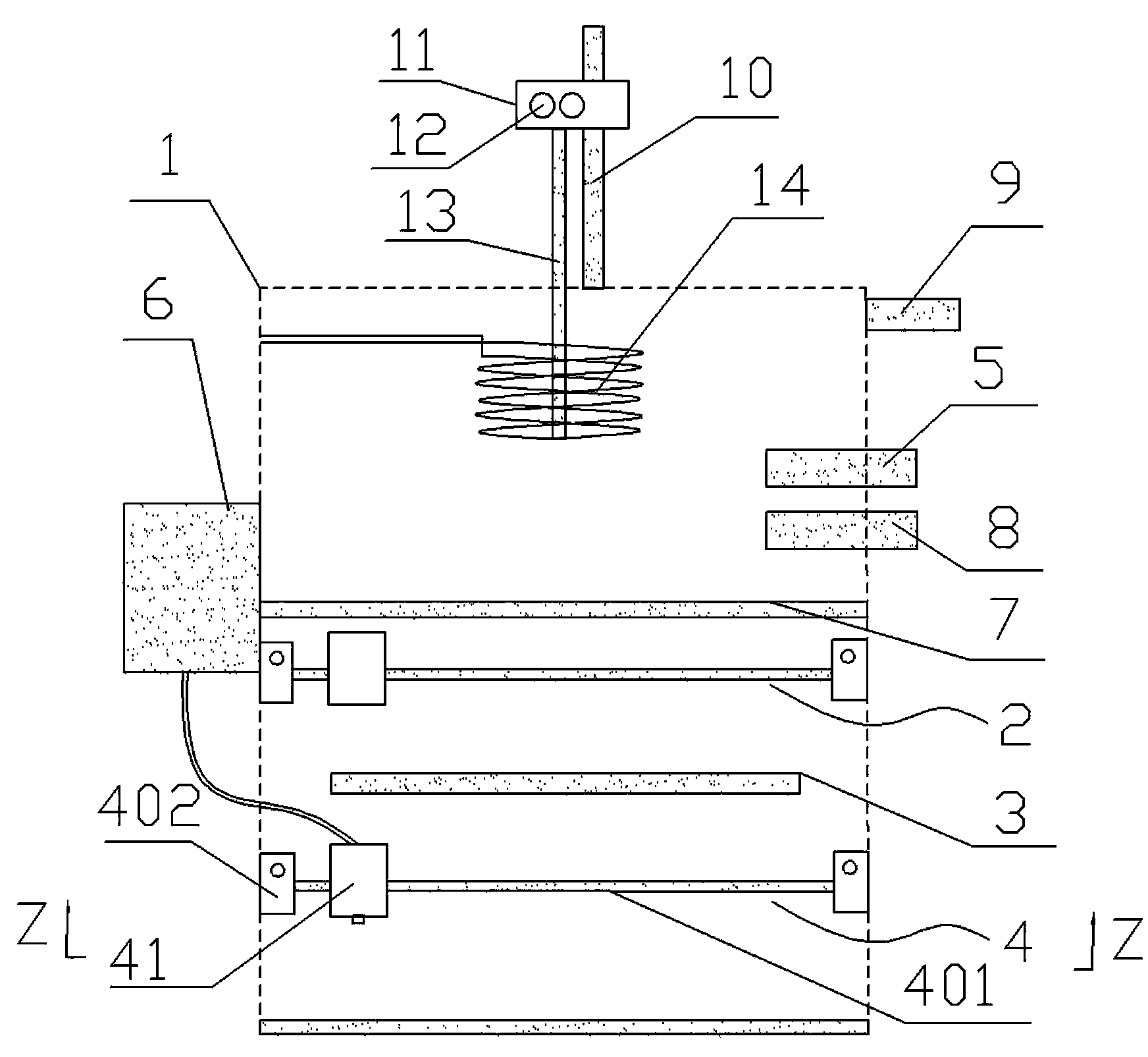

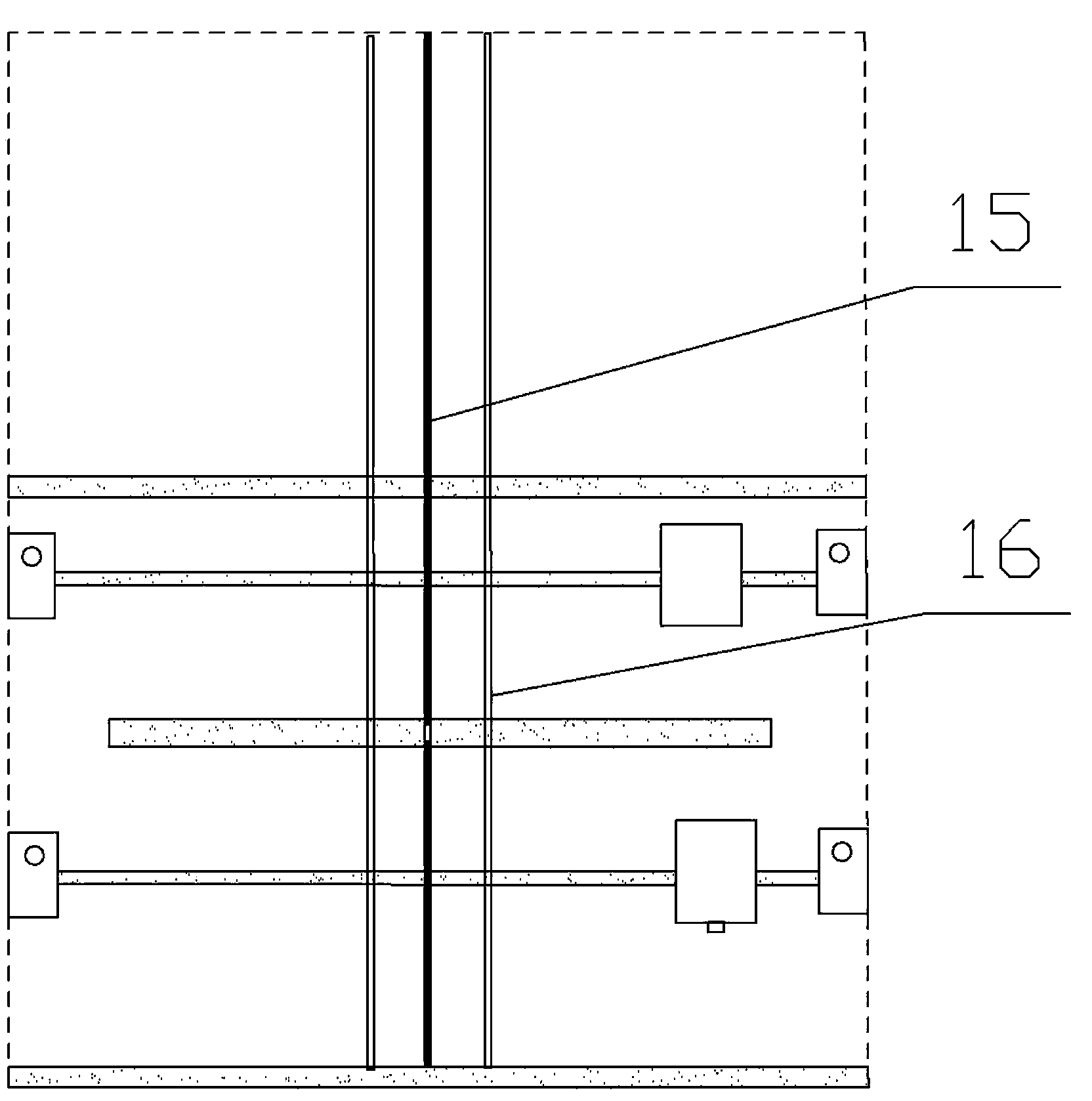

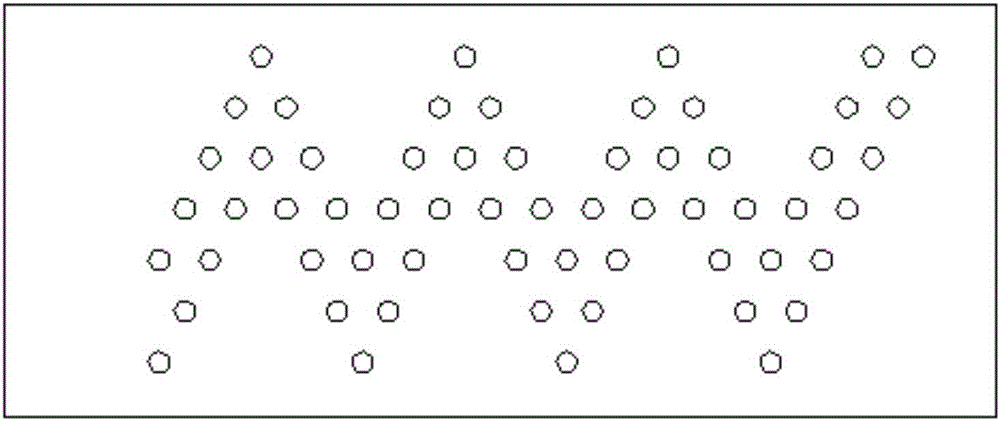

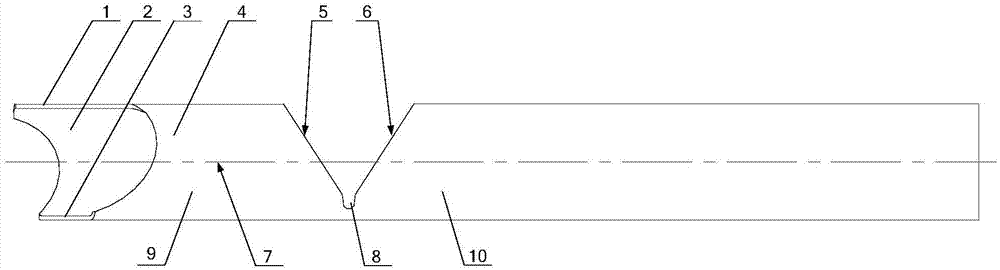

Method for engraving miniature two-dimensional code in glass laser

ActiveCN110626086ASufficient reaction timeAvoid smearingAblative recordingPicosecond laserLaser engraving

The invention relates to the technical field of laser engraving, in particular to a method for engraving a miniature two-dimensional code in glass laser. The method for engraving the miniature two-dimensional code in the glass laser comprises the following steps that a DATAMATRIX two-dimensional code encoding method is used for generating an initial two-dimensional code drawing file of a circle pattern; and a single-point mode two-dimensional code drawing file composed of a plurality of independent single points is generated according to the initial two-dimensional code drawing file of the circle pattern; processing delay parameters are arranged behind the each single point of the single-point mode two-dimensional code drawing file, and a target two-dimensional code drawing file is generated; a glass sample is located through a coaxial CCD camera, and the position to be processed is calculated; and an optical path is adjusted to enable the focused spot size of a laser beam to be smaller than a calibration value, a focus point of the laser beam is moved to the position to be processed inside the glass sample, and the two-dimensional code processing is carried out according to the target two-dimensional code drawing file. The tailing phenomenon caused by a galvanometer when the action time of a picosecond laser is extremely short is effectively prevented, and two-dimensional small-size engraving is enabled to be possible.

Owner:WUHAN HGLASER ENG CO LTD

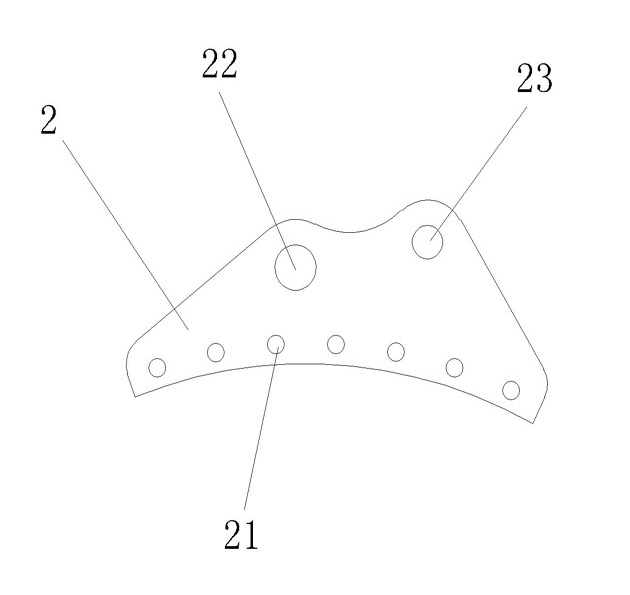

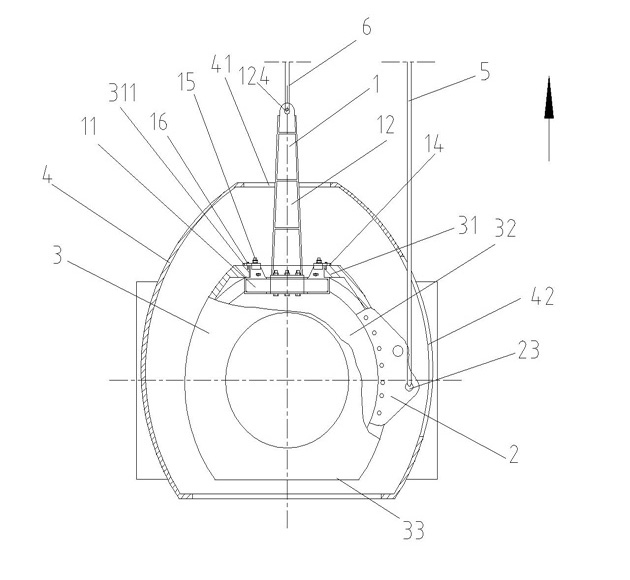

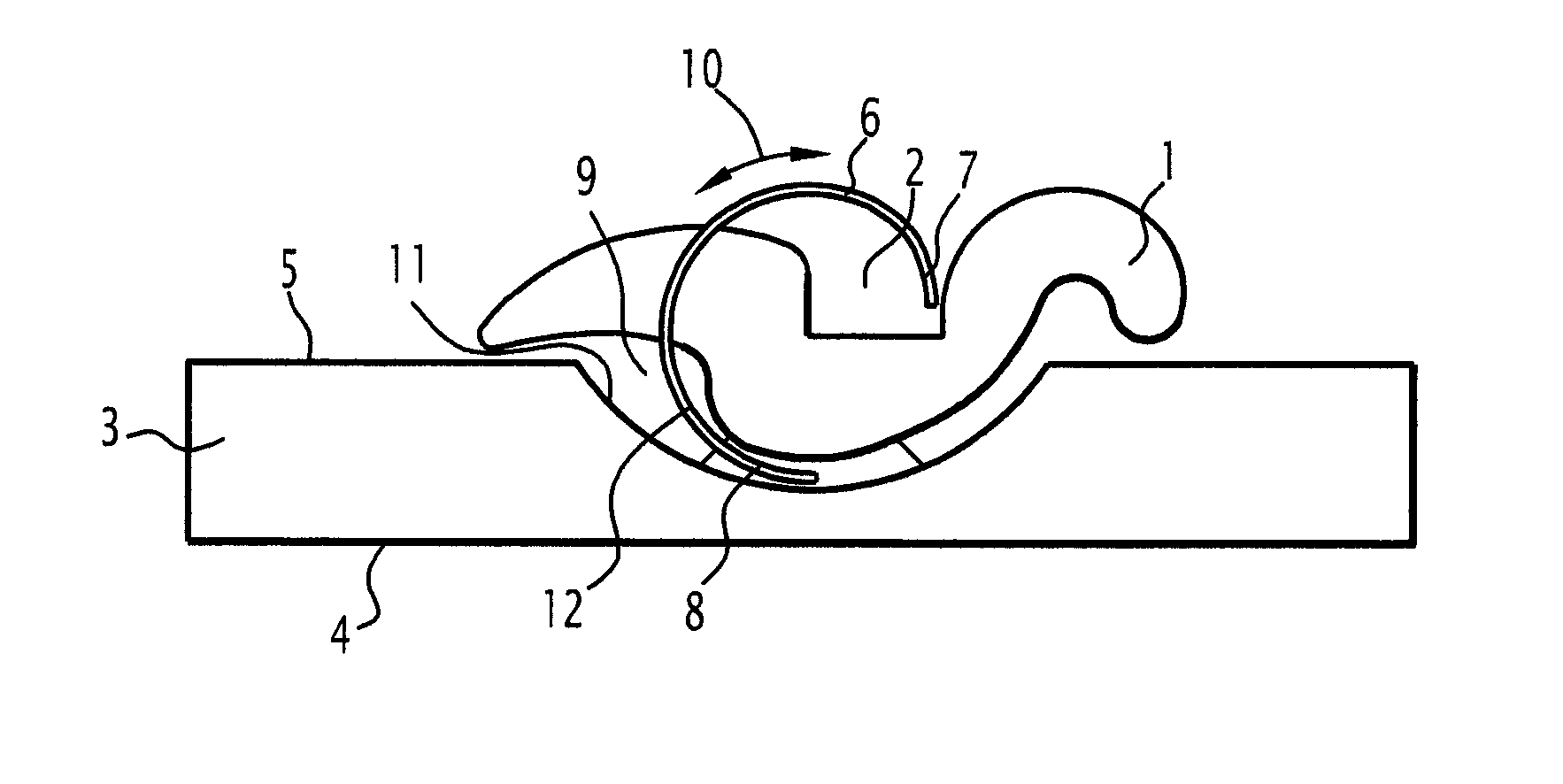

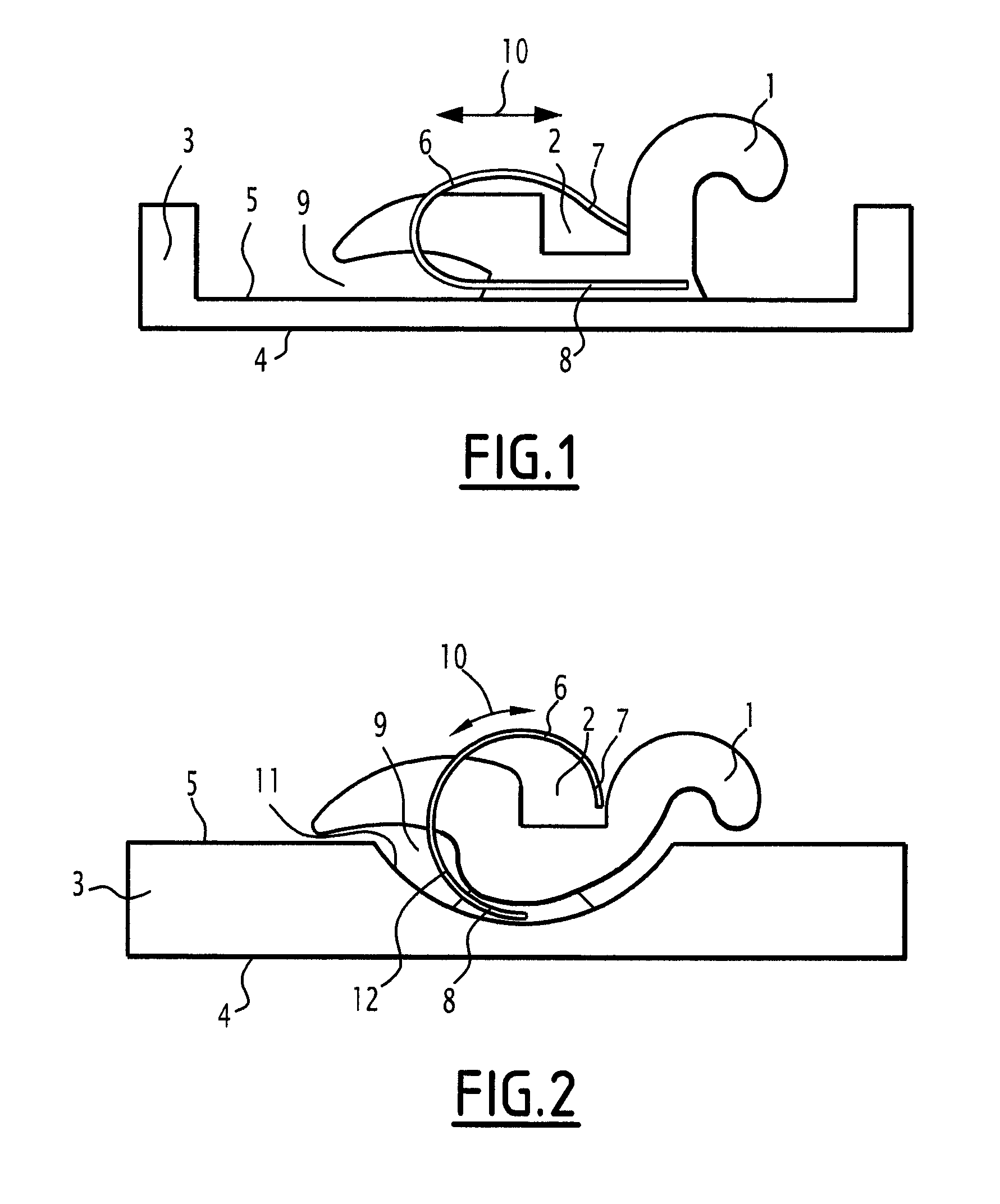

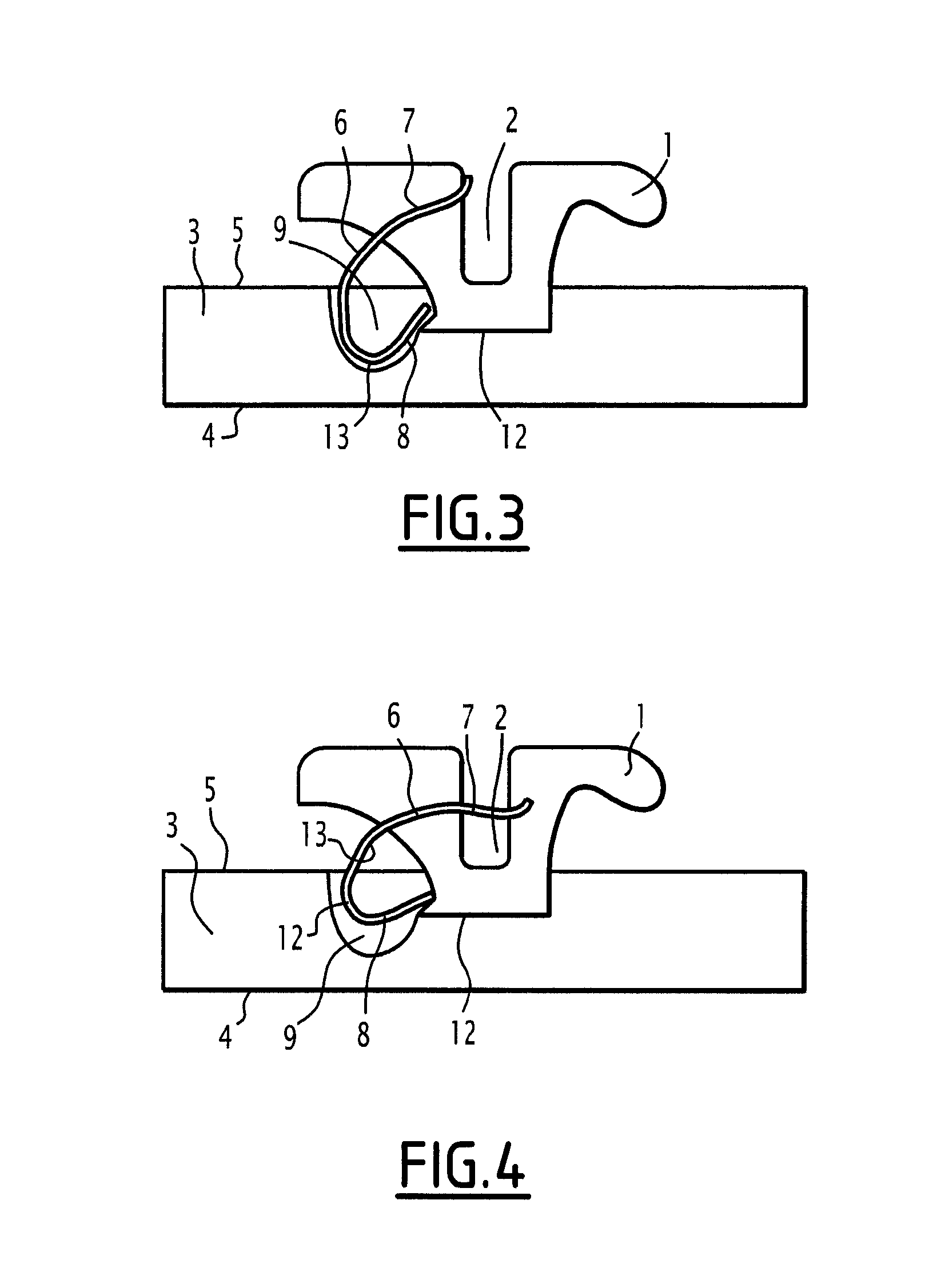

Assembly formed by a bracket, a clip and a base for an orthodontic apparatus, and orthodontic apparatus comprising same

An orthodontic assembly includes a self-ligating attachment having a groove for receiving an orthodontic arch. An elastic clip can be reversibly moved between an open position and a closed position sealing the groove. A base including an external surface and an occlusal surface, said external surface of the base supporting the attachment and said occlusal surface of the base being intended to rest on one of the patient's teeth. The aforementioned clip can be moved in an at least partially rotational manner between the open position and the closed position. Moreover, the area of the above-mentioned base that supports the attachment comprises a depression at least partially in the form of a cup and the clip is inserted into the depression when in the closed position.

Owner:CUZIN JEAN FRANCOIS

Forming method of composite material of ultra-large size special honeycomb structure

ActiveCN101422964ALocal enhancementMeet the requirements of bonding strengthLarge sizeHoneycomb structure

The invention belongs to the technical field of composite material manufacturing and shaping and relates to a shaping method of an oversize composite material part with special honeycomb cellular structure. The method includes the following steps of: (1) prefabricating a honeycomb cell component according to the size of a composite material shaping part; (2) cementing a coating on the upper surface and the lower surface of each honeycomb cell component and reserving a coating overlapping part and a honeycomb overlapping part respectively at two sides of each honeycomb cell component; (3) cementing a nylon gauze on the upper surface and the lower surface of the split joint seam in each honeycomb cell component; (4) encapsulating the honeycomb cell component after adhesion in a vacuum bag to be pressurized and solidified; and (5) continuing connection on the encapsulated vacuum bag to extend the size so as to encapsulate and pressurize the honeycomb cell component after adhesion in the vacuum bag. The invention separately prepares the honeycomb cell components, uses an oversize vacuum bag to block up the integral shaping of pressurization, satisfies the overall rigidity and flexibility, has no unrecoverable fold or crack in the cementing seam in bending and achieves the cementation and solidification requirements in normal temperature.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

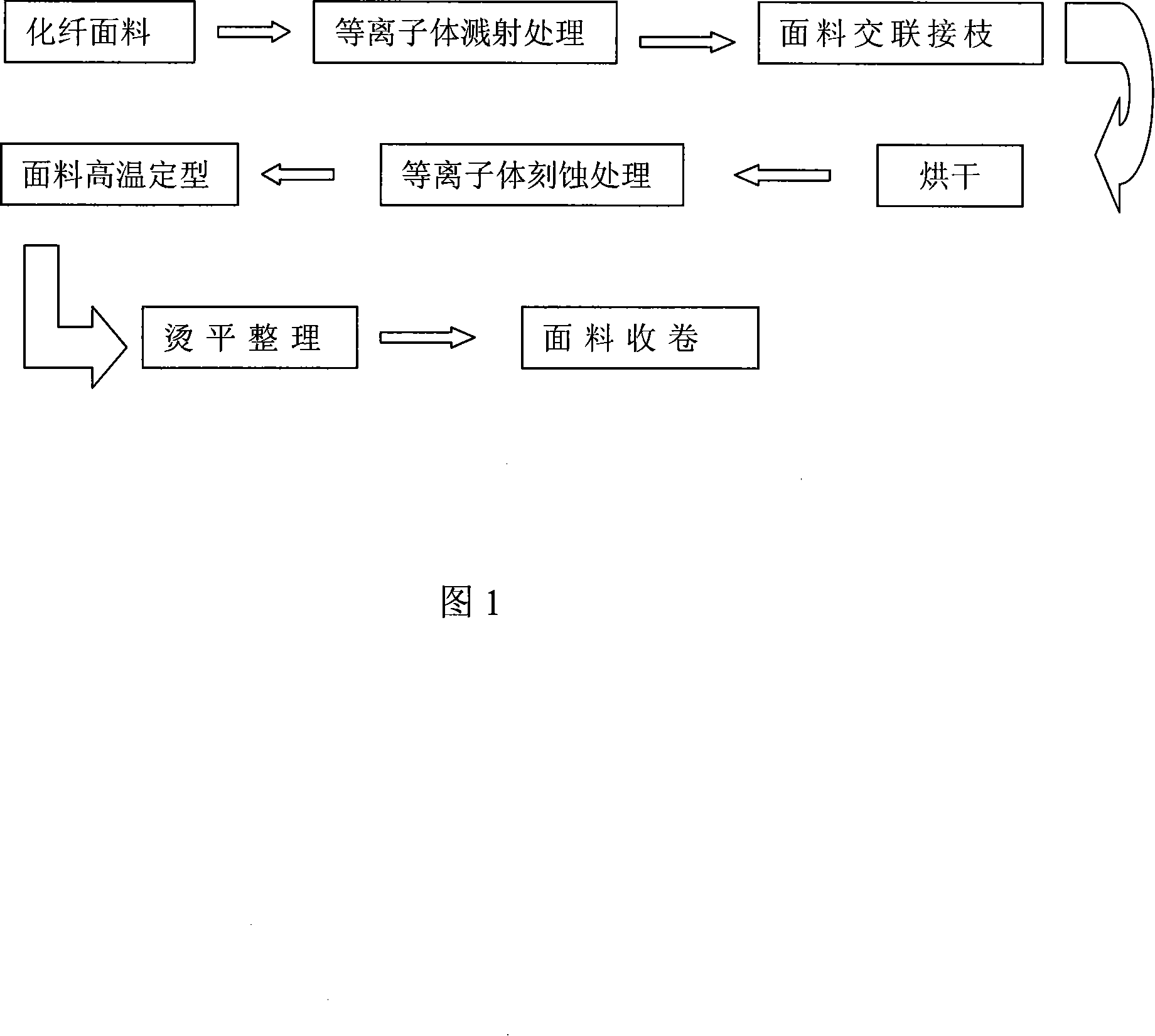

Chemical fiber plus material normal pressure plasma treatment method

InactiveCN101148821AIntensity is not affectedShort processing timeVacuum evaporation coatingSputtering coatingEmulsionPlasma treatment

The normal pressure plasma treating process of chemical fiber fabric includes the following four steps: plasma surface sputtering treatment of the chemical fiber fabric, surface cross-linking grafting, surface etching treatment, and high temperature setting finishing. In the surface cross-linking grafting, the chemical fiber fabric through the plasma surface sputtering treatment and with hydrophilic hydryscopicity is cross-linked and grafted with acrylate emulsion, polyglycol ester and antistatic agent to maintain the lasting hydrophilic hydryscopicity and prevent the generation of static electricity. The further plasma etching treatment can further raise the hydryscopicity, air permeability and adhesiveness of the chemical fiber fabric and improve the soft feeling and wrinkle resistance. The high temperature setting finishing can fix the performance of the chemical fiber fabric. The process can improve the performance of chemical fiber fabric greatly.

Owner:陈成泗 +2

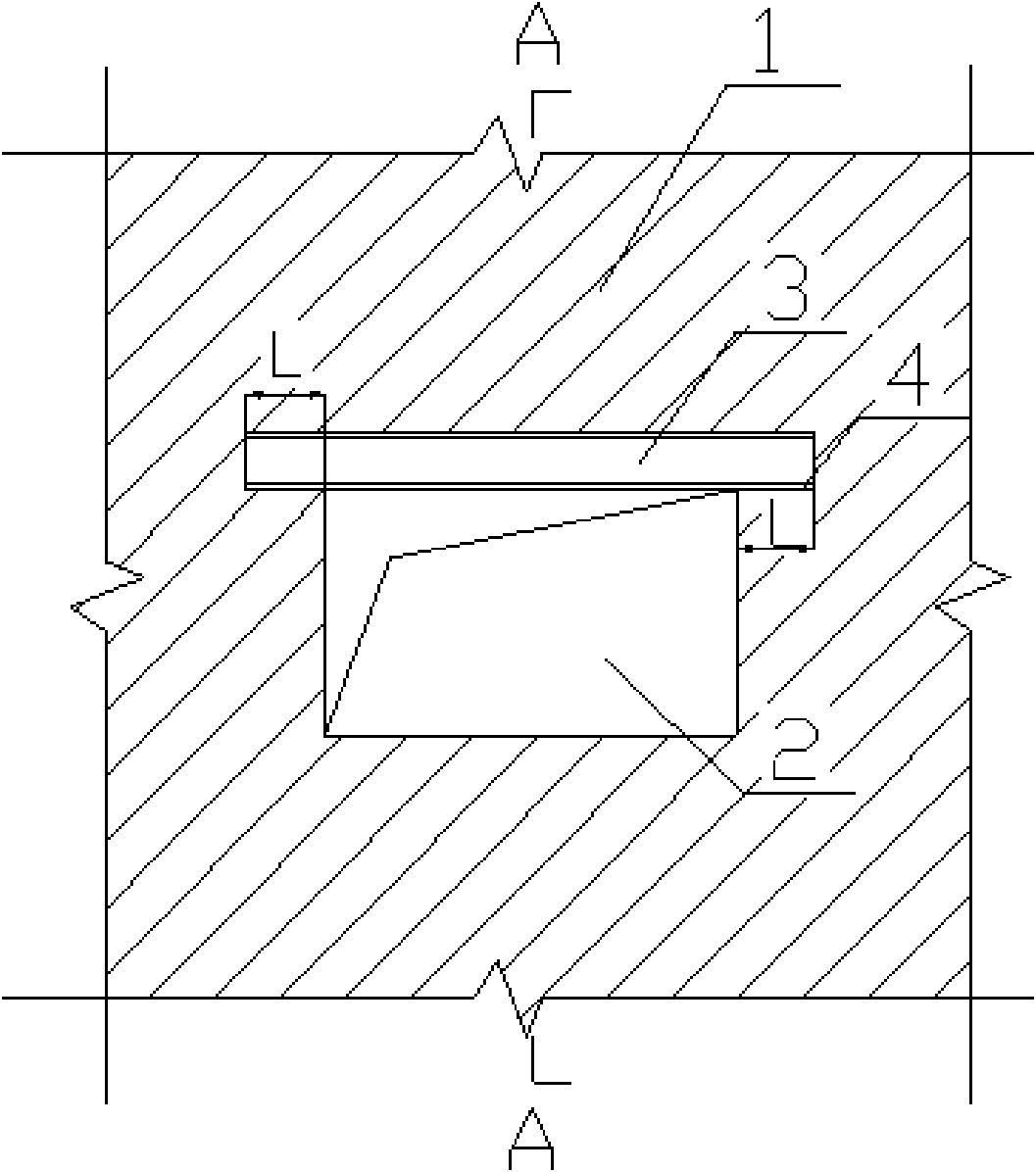

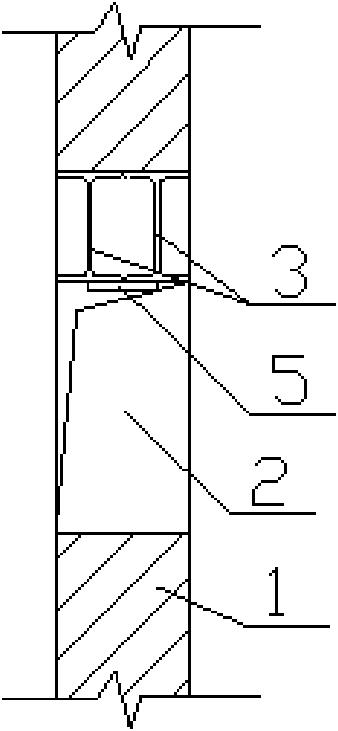

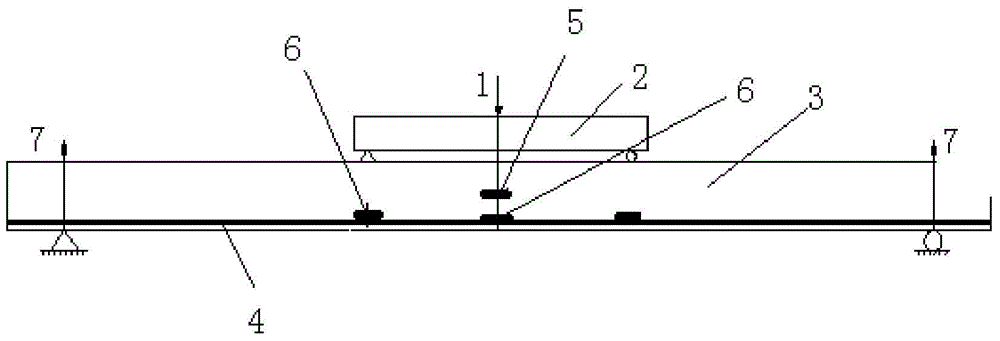

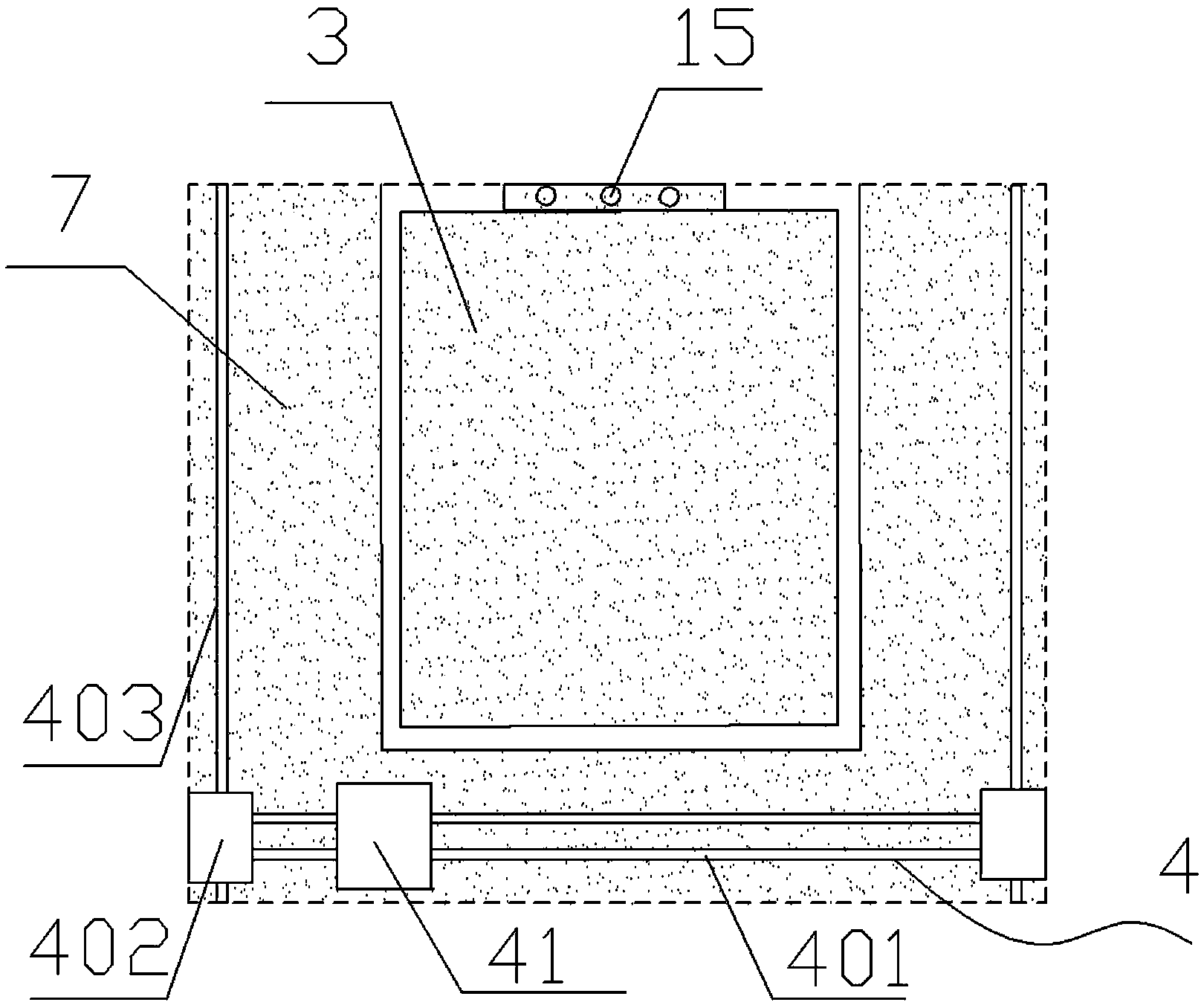

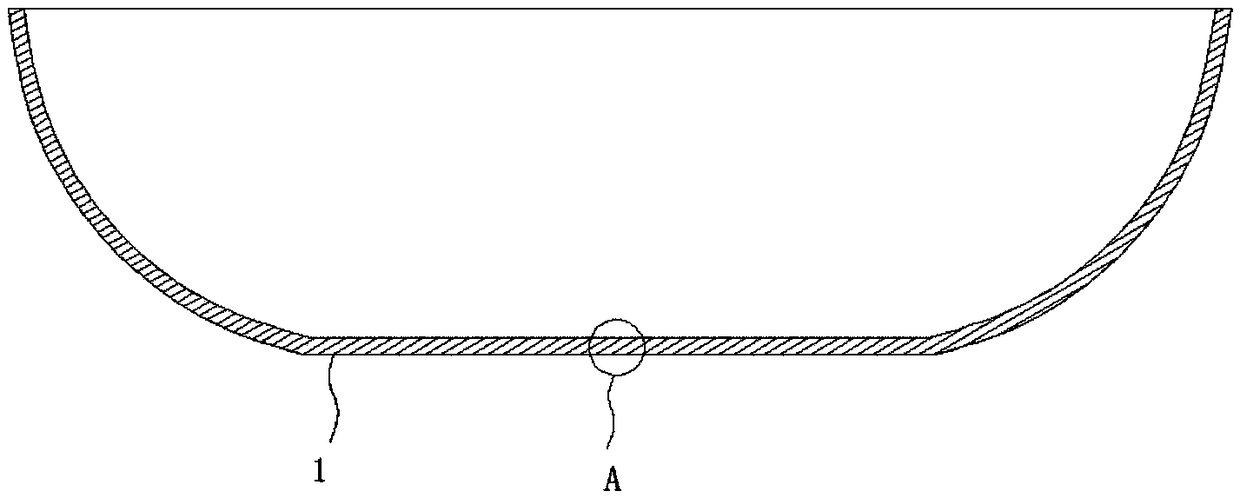

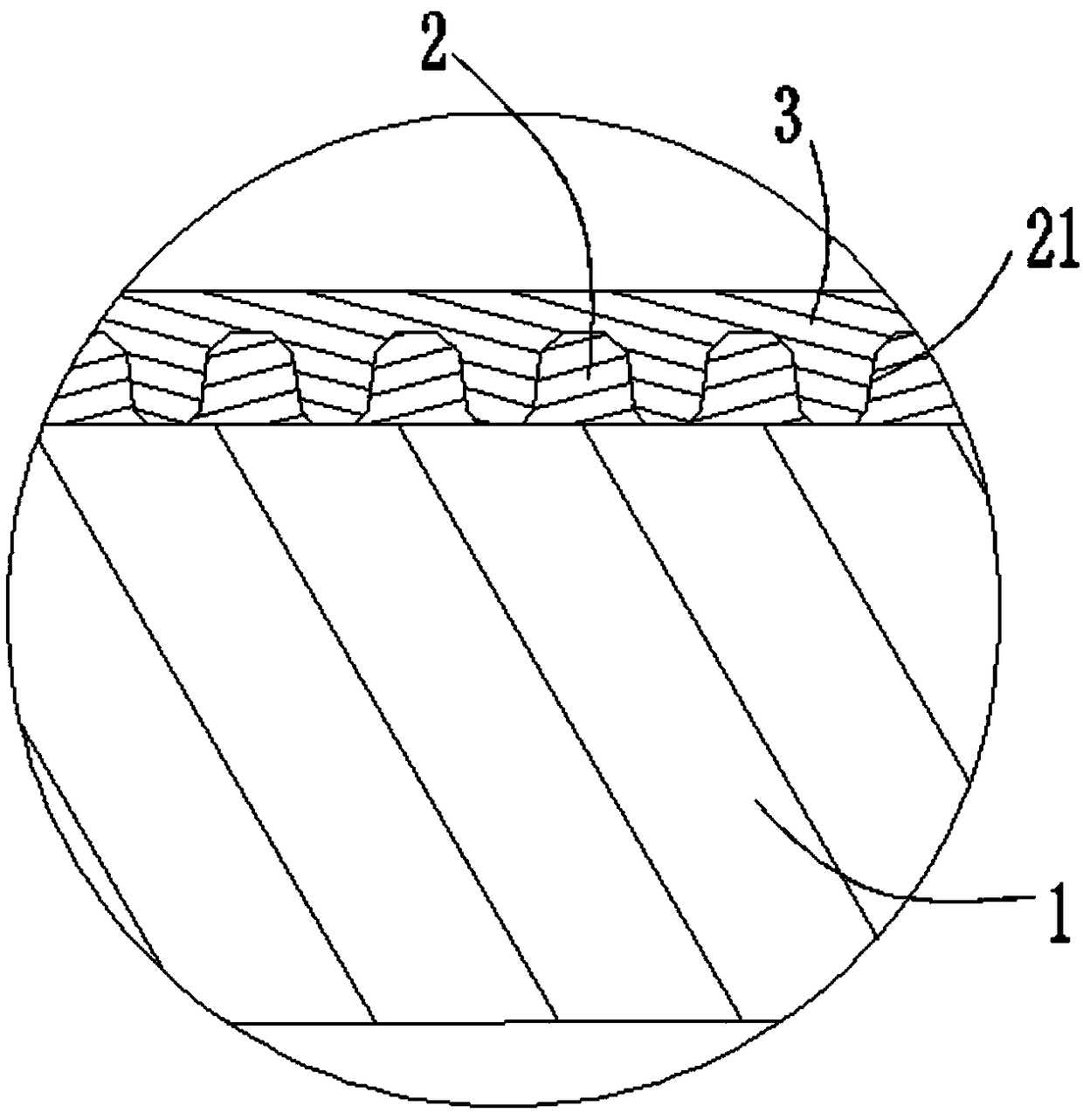

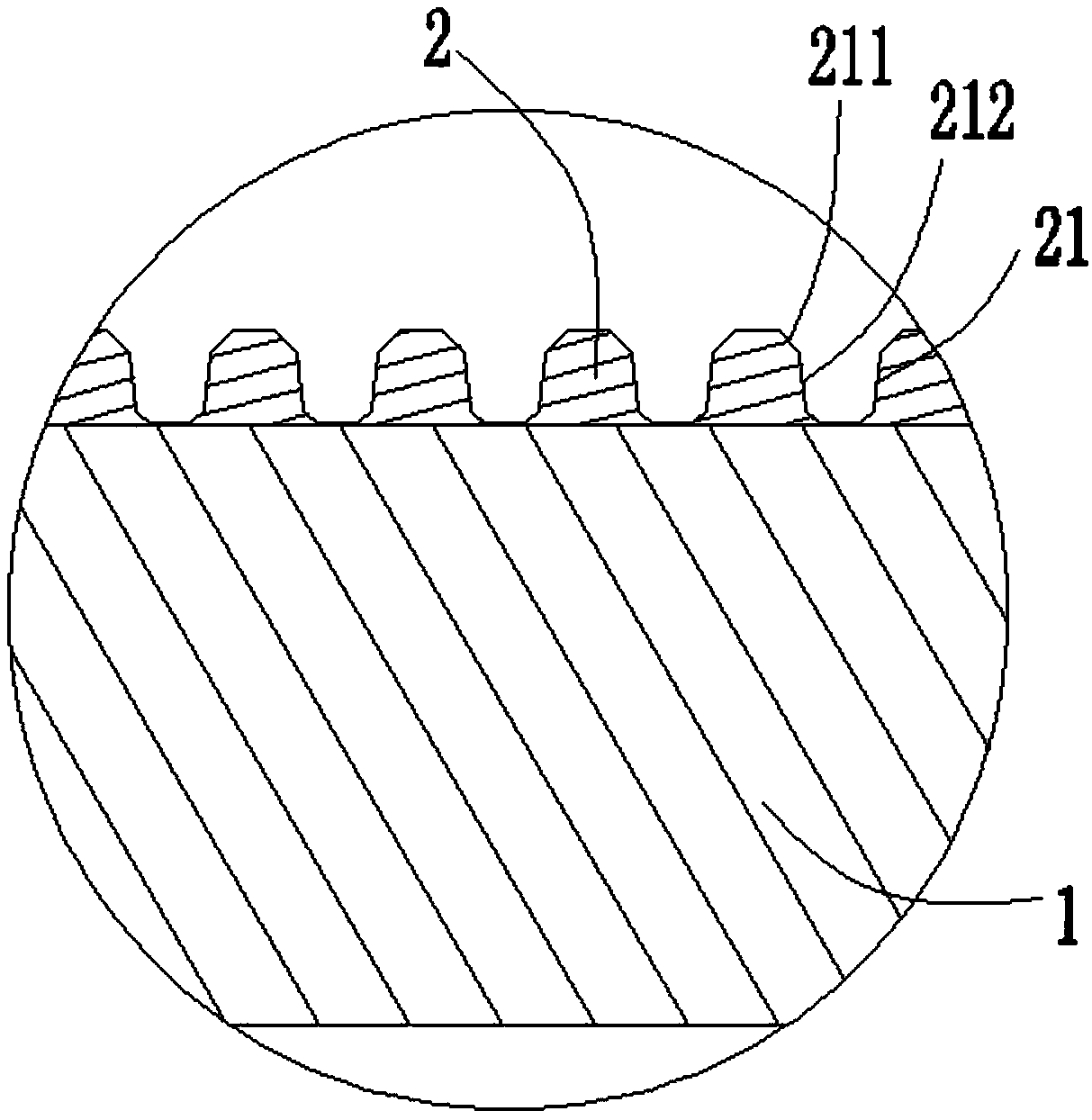

Cave mouth structure on bearing wall and method for forming cave mouth thereon

InactiveCN101638920AIntensity is not affectedStability is not affectedWallsBuilding repairsStructural engineeringCave

The invention discloses a cave mouth structure on a bearing wall and a method for forming the cave mouth thereon. The structure comprises a bearing wall body (1) and a cave mouth (2) formed on the bearing wall body (1), wherein a steel member (3) is arranged on the bearing wall body (1) above the cave mouth (2), and both ends of the steel member (3) are respectively positioned in bearing slots (4)on both ends of the upper part of the cave mouth (2). The invention adopts the structure that the steel member is arranged above the cave mouth which needs to be formed, both ends of the steel memberare supported on the bearing wall on both ends of the upper edge of the cave mouth, and therefore a larger cave mouth can be formed on the wall body without demolishing the wall body or unloading load on the wall; and the strength and the stability of the wall can be prevented from being influenced.

Owner:GUIYANG AL-MG DESIGN & RES INST

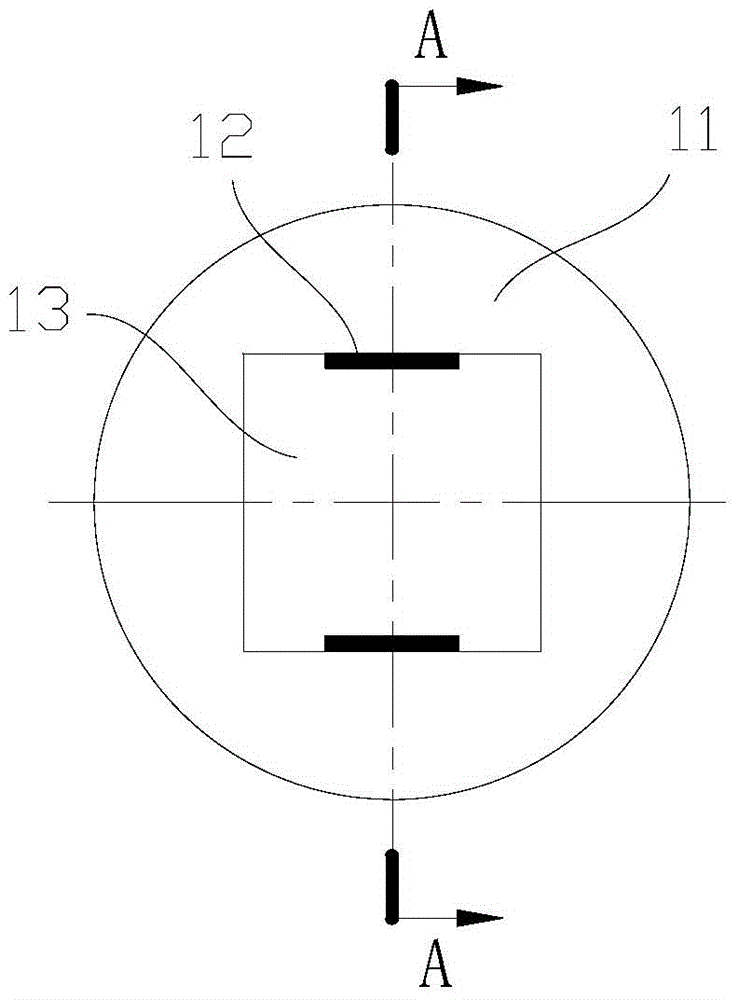

Measurement specimen and measurement method for interface characteristic of embedded rib reinforced concrete beam

InactiveCN104458384AAvoid interferenceDoes not interfere with test accuracyPreparing sample for investigationMaterial strength using steady bending forcesStrain gaugeEngineering

The invention discloses a measurement specimen and a measurement method for an interface characteristic of an embedded rib reinforced concrete beam. The specimen comprises a combined reinforced rib, wherein a through groove is formed in the center of the section of the combined reinforced rib in the axial direction; strain gauges are uniformly distributed on the inner wall of the through groove along the axial direction of the through groove. The method comprises the following steps that the combined reinforced rib is embedded into the concrete beam, and according to the conventional four-point bending static load test, an automatic static strain acquisition instrument records data epsilon f of the strain gauges and the cracking load Pcr, the yield load Py and the ultimate load Pu of the beam in real time; according to the strain data measured actually, the shearing strength of an interface of the combined reinforced rib or a CFRP rib with a glue agent is obtained by calculation; the Pu theory value is obtained by calculating according to the calculating method of the concrete reinforcing strength in the concrete reinforcing theory. By comparing the errors of the Pu theory value with the Pu, the result shows that the specimen can be used for improving the measurement precision of parameters of the interface characteristic of the reinforced concrete beam, and the strain measurement is convenient and easy.

Owner:HUNAN INSTITUTE OF ENGINEERING

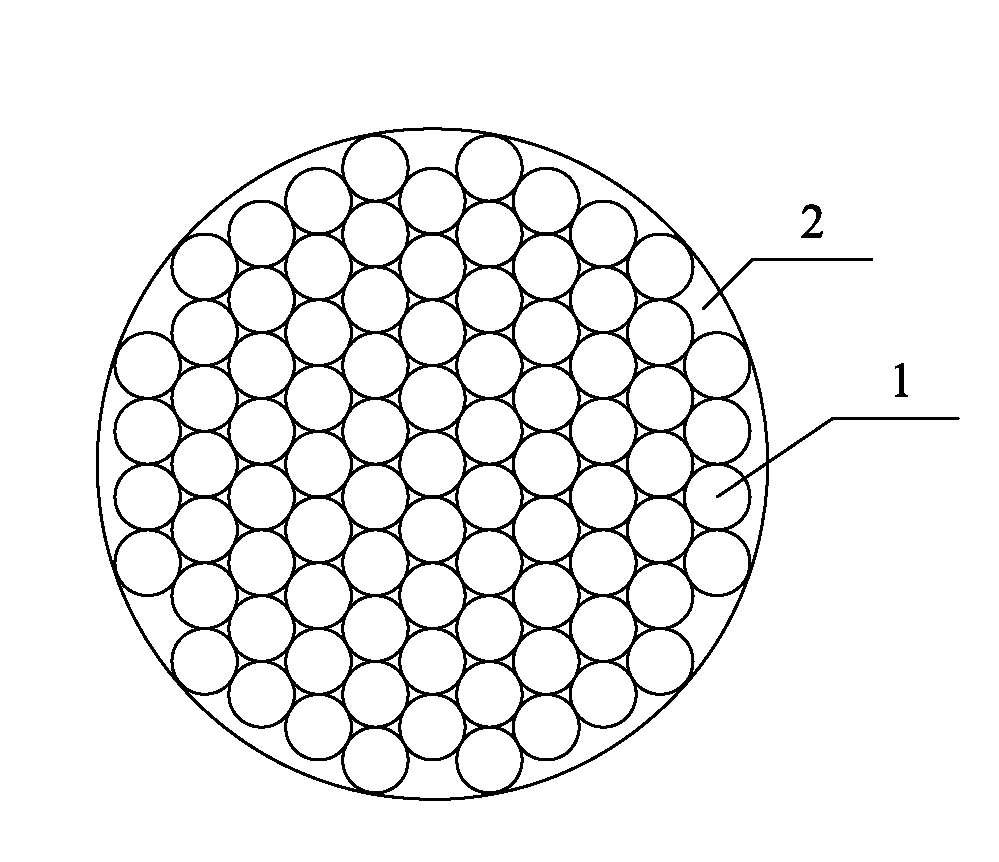

Monofilament-shaped ultrahigh molecular weight polyethylene fiber and continuous preparation method thereof

InactiveCN102797089AImprove wettabilityImprove adhesionPhysical treatmentAdhesivesPolymer scienceWhole body

The invention discloses a monofilament-shaped ultrahigh molecular weight polyethylene fiber and a continuous preparation method thereof. The monofilament-shaped ultrahigh molecular weight polyethylene fiber is formed by adhering 50-570 ultrahigh molecular weight polyethylene fibers to form a whole body in parallel, and a matrix resin layer is coated on an outer wall of the monofilament-shaped ultrahigh molecular weight polyethylene fiber. The continuous preparation method comprises the following steps of: (1) material selection: selecting 50-570 ultrahigh molecular weight polyethylene fibers; (2) performing fiber surface treatment; (3) twisting the fibers to form a single strand; (4) uniformly tensioning the fibers, and removing the static electricity; (5) sizing treatment; and (6) performing heat setting to form the monofilament-shaped ultrahigh molecular weight polyethylene fiber, and finally, winding into coils. According to the monofilament-shaped ultrahigh molecular weight polyethylene fiber and the continuous preparation method thereof, the wear resistance of the fiber is greatly improved on the premise of basically not influencing the strong performance of the fiber, the service life of the fiber can be greatly prolonged, complex special equipment is not required, and the construction cost is low; and moreover, the monofilament-shaped ultrahigh molecular weight polyethylene fiber can be widely applied to the fields of industry, national defense, sports, oceans and the like.

Owner:SHANDONG ICD HIGH PERFORMANCE FIBRES CO LTD

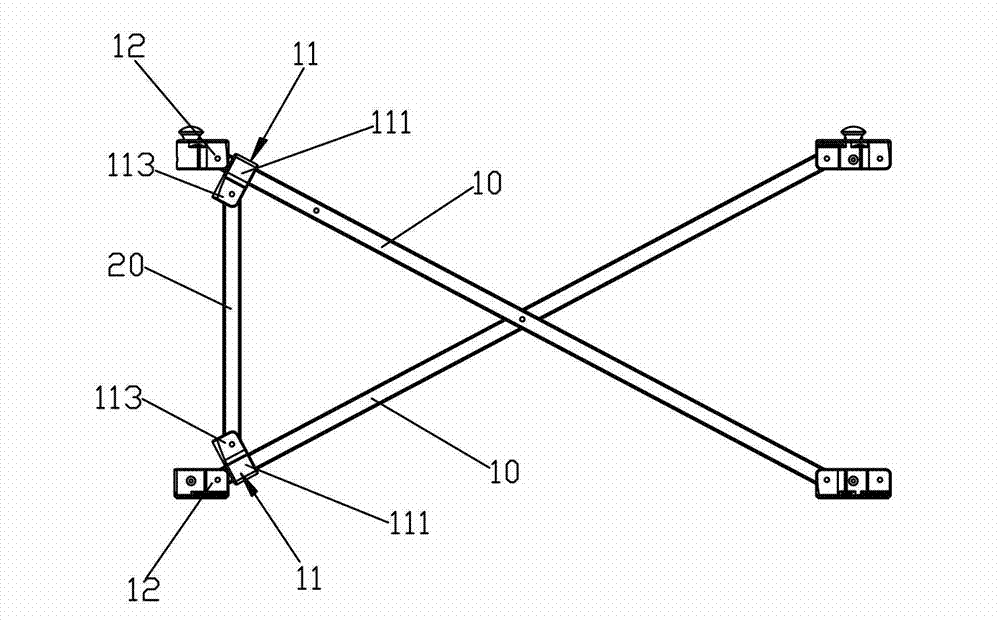

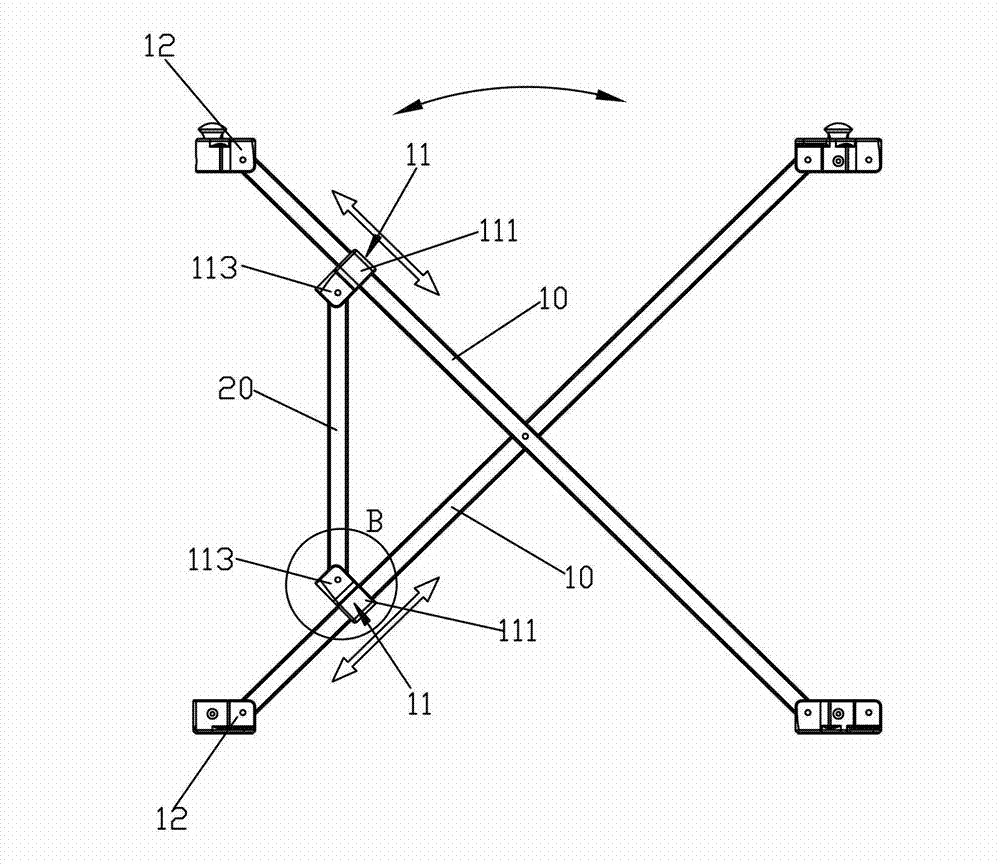

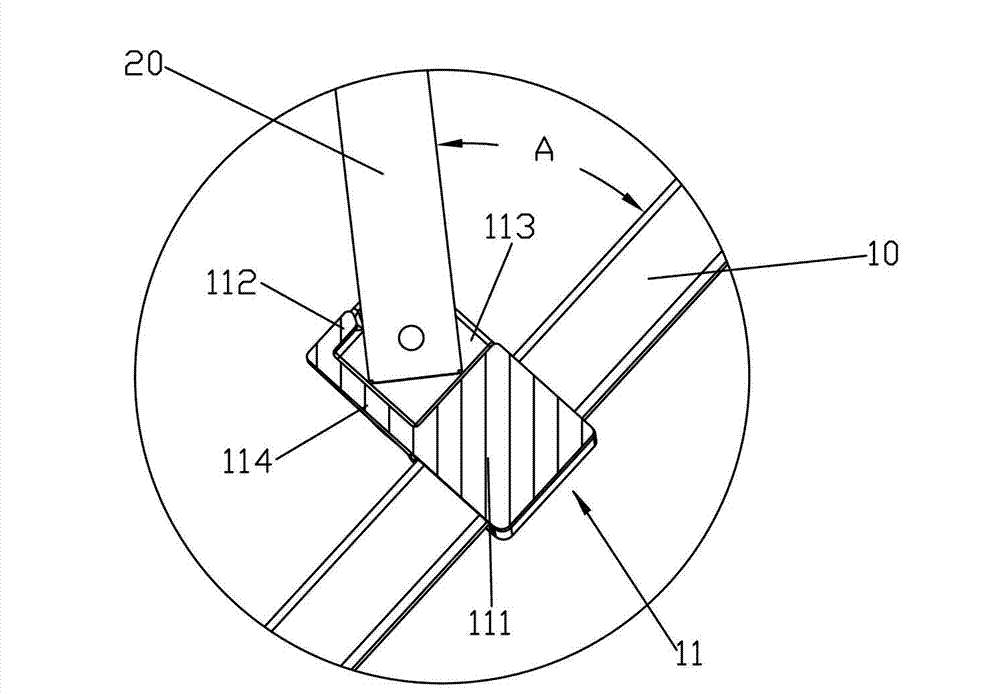

Folding support mechanism, folding bed stand and folding seat bracket

ActiveCN103190779AAvoid stuck phenomenonLess materialDismountable chairsFoldable chairsMechanical engineeringUltimate tensile strength

The invention discloses a folding support mechanism, a folding bed stand and a folding seat bracket. The folding support mechanism comprises a pin joint rack which includes two connecting rods in pin joint; the folding support mechanism further comprises a support bar; the two connecting rods are slidably connected with a sliding seat respectively, two ends of the support bar are rotatably connected with the sliding seats of the two connecting rods respectively, and maximum rotation unfolding angles of the support bar relative to the two connecting rods are no more than 90 DEG. According to the invention, since the maximum rotation unfolding angles of the support bar relative to the two connecting rods are no more than 90 DEG, the support bar is rotary relative to the two sliding seats; thus, the phenomenon of deadlocking is avoided, it is guaranteed that the support bar moves to a position where the support bar abuts against the two connecting rods so as to maintain unfolding, and the following beneficial effects are obtained: a) unfolding can be maintained by only using one support bar, so the advantages of saving of materials, low cost and light weight are obtained; b) demands for unfolding and folding can be satisfied at the same time; c) unfolding and folding are convenient and smooth, and the folding support mechanism has a long service life; and d) strength of the connecting rods are not influenced.

Owner:陈鹭娟

Bamboo tableware dyeing method with sucrose as dye

InactiveCN103203787ASufficient supplyLow costWood treatment detailsPulp and paper industrySucrose solution

The invention discloses a bamboo tableware dyeing method with sucrose as a dye and relates to a bamboo tableware dyeing method. The bamboo tableware dyeing method comprises the following steps of: by taking the sucrose as a dye, dissolving the sucrose in water to prepare a sucrose solution with the mass concentration of 3-10 percent, dipping the bamboo tableware into the sucrose solution to sufficiently absorb the sucrose solution, draining moisture, and then putting the bamboo tableware into a drying oven to dry at 130-190 DEG C, so that the bamboo tableware is dyed into the sucrose color. The color depth adjustment of the sucrose is implemented by controlling the temperature. The bamboo tableware dyeing method has the advantages of sufficient raw material supply, low cost, simple equipment and easy purchasing as the edible sucrose is used as a raw material; as the food tableware is dyed in a pure environment-friendly dyeing manner, no any pollution is caused in the food production process, and the bamboo tableware dyeing method is free of secondary pollution in the production process and beneficial to friendliness environment of enterprises.

Owner:SHENYANG UNIV

Automobile windscreen

InactiveCN103407348AIntensity is not affectedPlay a thermal insulation effectWindowsWindscreensSilicon dioxideAnti-fog

The invention relates to an automobile windscreen which comprises an outer layer windscreen and an inner layer windscreen, wherein a cavity is arranged between the outer layer windscreen and the inner layer windscreen, and transparent and heat insulation silicon dioxide aerogels are filled in the cavity. Compared with the prior art, the automobile windscreen has a good anti-fog performance and a strength close to that of the normal windscreen.

Owner:昆山振天智能化设备有限公司

Conductive fibre

InactiveCN101158058AAddressing Permanent ConductivityStretchability is not affectedElectroconductive/antistatic filament manufactureMasterbatchHot melt

A conductive fiber is characterized in that the fiber is composed of conductive masterbatch and fiber grade resin sections, wherein, the weight percentage of conductive masterbatch in the fiber is from 20% to 30%. The production method includes (1) coupling agent, carrier resin and dispersant are added to dried conductive powder for mixing and then the mixture is melted and extruded, cooled and granulated through a twinscrew so as to prepare conductive masterbatch; (2) fiber grade PP resin sections are added in the conductive masterbatch and spun by adopting a hot-melt extrusion spinning method. The invention has the advantages that (1) under the precondition of no change of the physical and chemical properties of the polypropylene fiber, the invention solves the problem of the permanent conductivity of polypropylene fiber basically and effectively to achieve an antistatic effect without impacting other fine properties of polypropylene fiber; (2) the tensility, strength and color fastness of the fiber can not be affected and the fiber is suitable for making various clothing and costume; (3) the invention has mature technique and low production cost, thus being able to be applied and popularized.

Owner:TIANJIN SAIYUAN HEALTH PROD +1

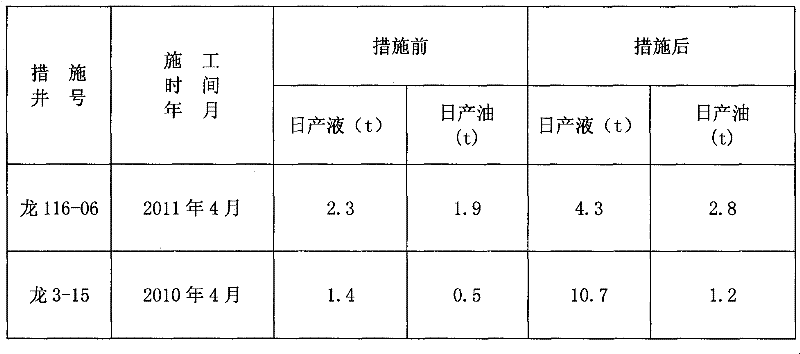

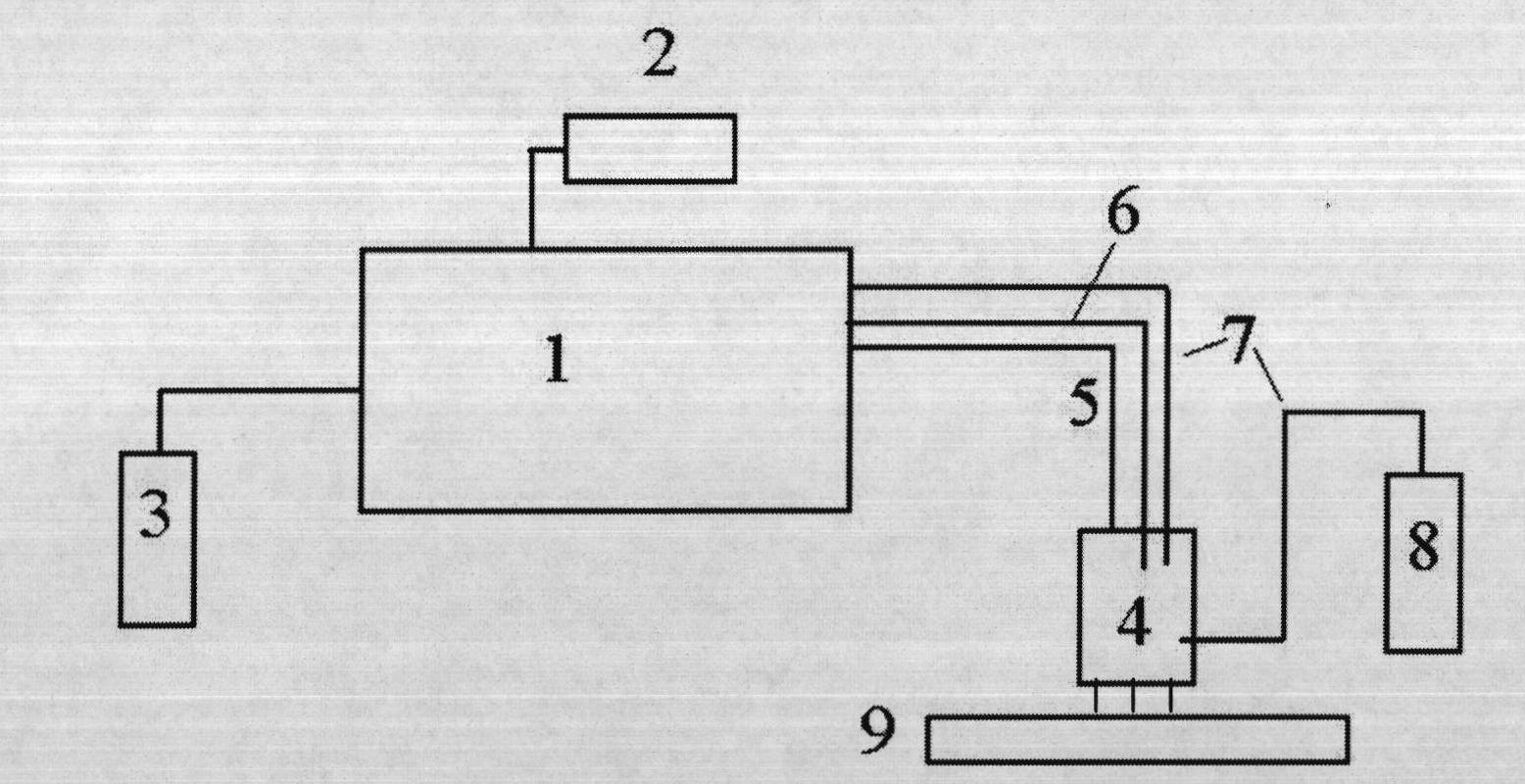

Radial hydraulic jetting drilling technology

InactiveCN102312655AHas the effect of increasing productionLow costLiquid/gas jet drillingDirectional drillingHigh pressurePermeation

The invention discloses a radial hydraulic jetting drilling technology, which solves the problems that in the existing radial jetting drilling technology, the cracking position and the crack direction can not be controlled, and a hydraulic cut slot and a deep penetration hole oil layer have small construction radii. In the technology, a cutting knife is used for cutting a window in the oil layer sleeve pipe position to be constructed, high-pressure fluid is generated through a ground high-pressure circulation generation device, small directional boreholes with the diameter being 40mm to 50mm and the length being 100m are jet in the required direction and depth through the rock breaking effect of high-pressure hydraulic jetting and pass through a pollution zone to be connected with bypassed oil regions, the aerial drainage radius is increased, and the permeation condition is improved, so the oil well yield is increased, and the oil layer recovery ratio is improved.

Owner:ZHAODONG HUAYING OILFIELD DRILLING TECH SERVICE

Equipment punching coding method

ActiveCN105318849ASimple processing methodIntensity is not affectedMeasurement devicesRecord carriers used with machinesPunchingUltimate tensile strength

The invention relates to an equipment punching coding method which is a coding and identification method used for equipment and logging tools under a petroleum exploitation environment. A plurality of small holes are formed in the logging equipment, and the equipment is coded and identified, so that clear identification is ensured, the strength of the working equipment is prevented against influences, and the damage prevention capability and the recognition rate of codes are improved.

Owner:施永生

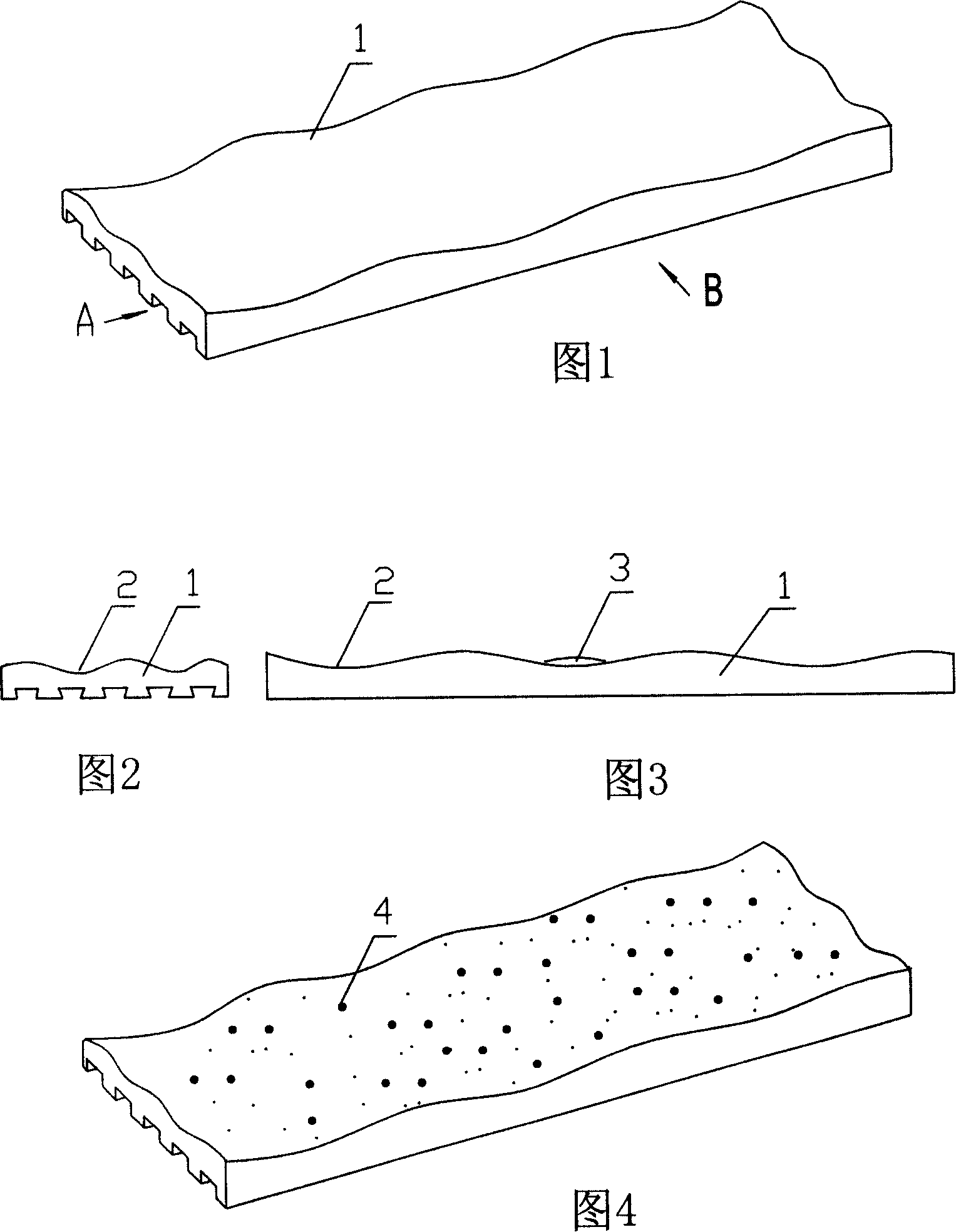

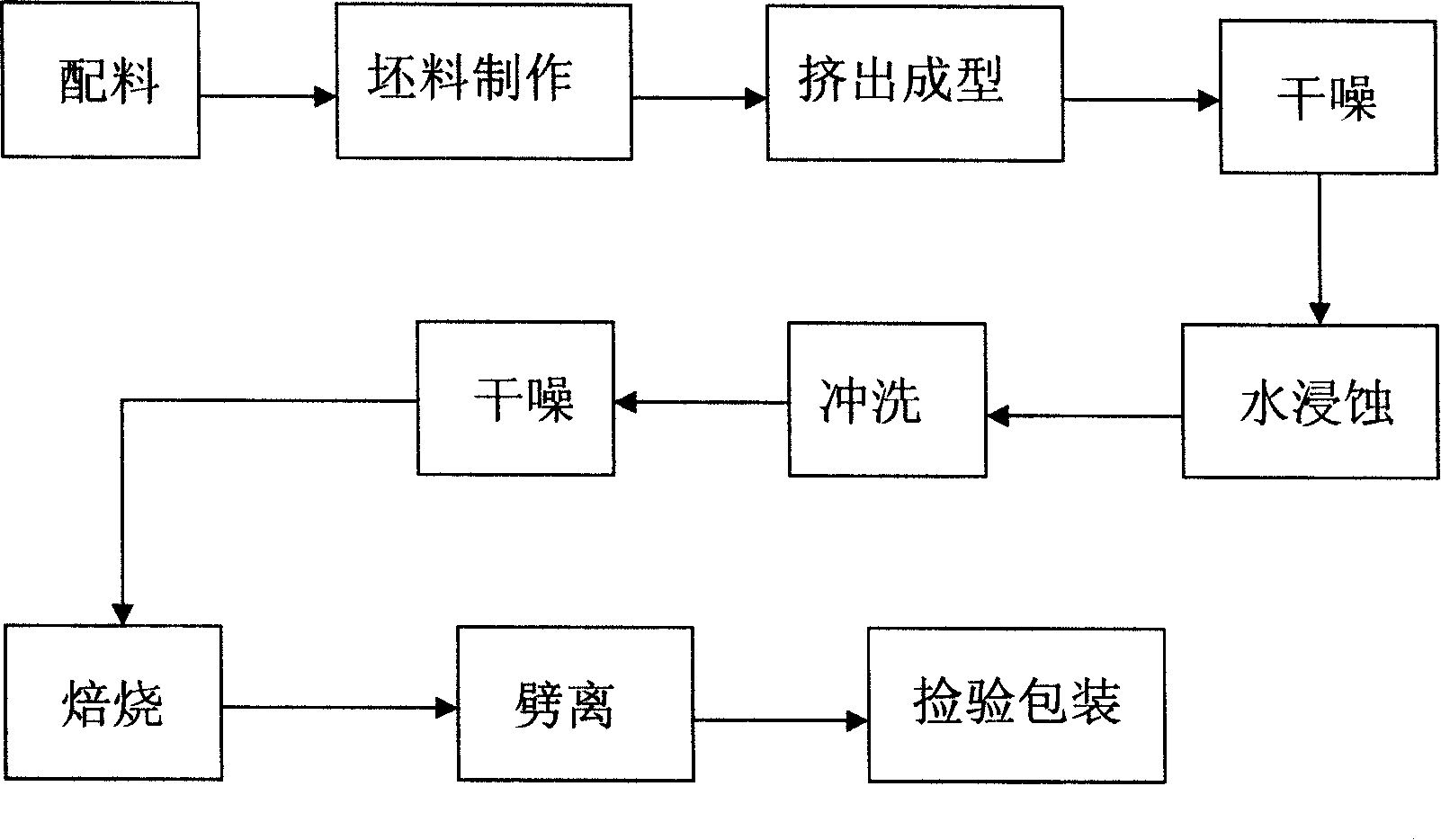

Natural water erosion face ceramic decoration split tile and its production method

InactiveCN101173552AUnique artistic effectSatisfy the pursuit of natureCovering/liningsSidewalk pavingsAdobeBrick

The invention relates to a ceramic decorative detached brick with natural water erosion surface, comprising an adobe made of same or different colored blanks, the brick surface is water erosion surface, namely a plurality of rugged pits or cambered surfaces or natural round pitting surfaces different depth generated due to water immersion and erosion are arranged on the surface of the brick. Compared with the prior detached brick, the production method is characterized in that the water erosion and flushing process are added between the drying process and the calcination process, the drying process is as follow: immersing the dry adobe surface of detached brick under water 1 to 3mm for 1 to 10 minutes, when the immersed part fully softened, washing the brick surface with fresh water, thus a plurality of rugged pits or cambered surfaces or water erosion surfaces with the depth of 0.1 to 3mm are formed on the brick surface, then calcining the adobe after drying. The surface of the brick produced with the method has smooth rugged pits which are similar to the stone surface eroded or flushed by water, and appears the unique artistic effect; furthermore, the brick surface has no scratch; the appearance is beautiful, and the brick body is higher in strength and more corrosion resistant.

Owner:柳州市奋进建筑材料有限责任公司

Method, equipment and system for manufacturing metal product and control method of equipment

ActiveCN104259391ARealize automated productionIncrease productivityCasting plantsMolten metal supplying equipmentsEngineeringSlurry

The invention relates to a method, equipment and system for manufacturing a metal product and a control method of the equipment. The method comprises the following steps: firstly using a 3D printing method to print a model of the metal product to be manufactured with a fusible material to form a fusible material male die, meanwhile conducting the 3D printing on the periphery of the fusible material male die to form a fusible material female die, injecting high-temperature-resistant material slurry into a cavity defined between the fusible material male die and the fusible material female die, drying and molding the high-temperature-resistant material slurry, and meanwhile after the fusible material is molten, forming a high-temperature-resistant material female die, injecting molten metal in the high-temperature-resistant material female die, and cooling the molten metal to form the model of the metal product. With adoption of the equipment and the method disclosed by the invention, the production automation for the metal product with any shape is achieved, the production precision is high, and the costs for production and the equipment are low.

Owner:佛山市顺德区韩顺纪精密金属有限公司

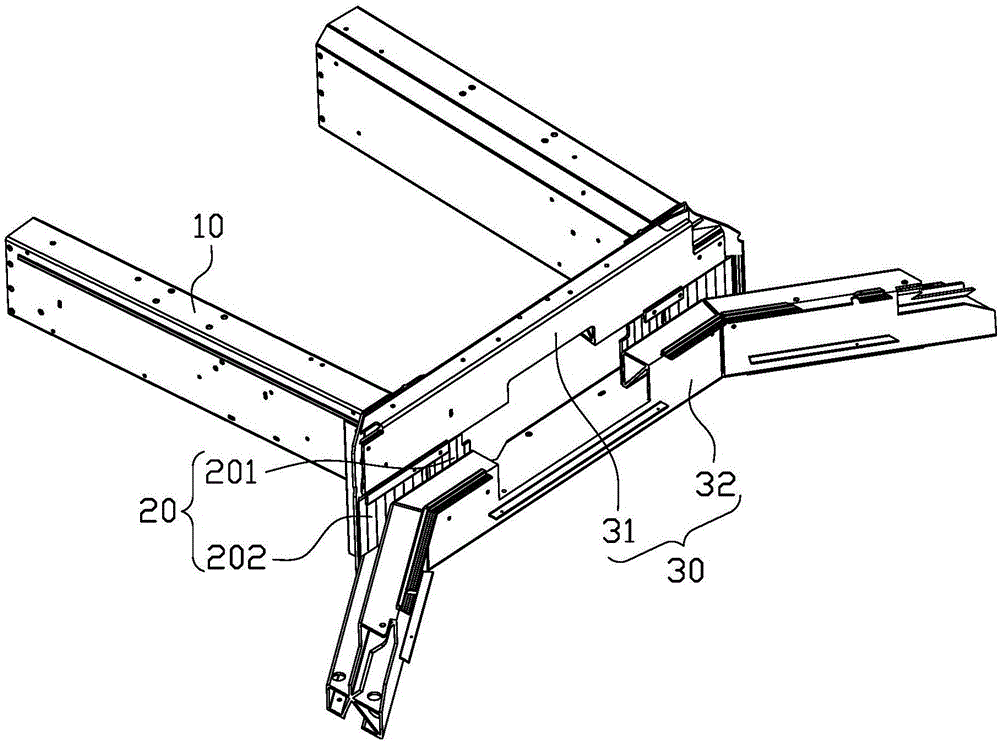

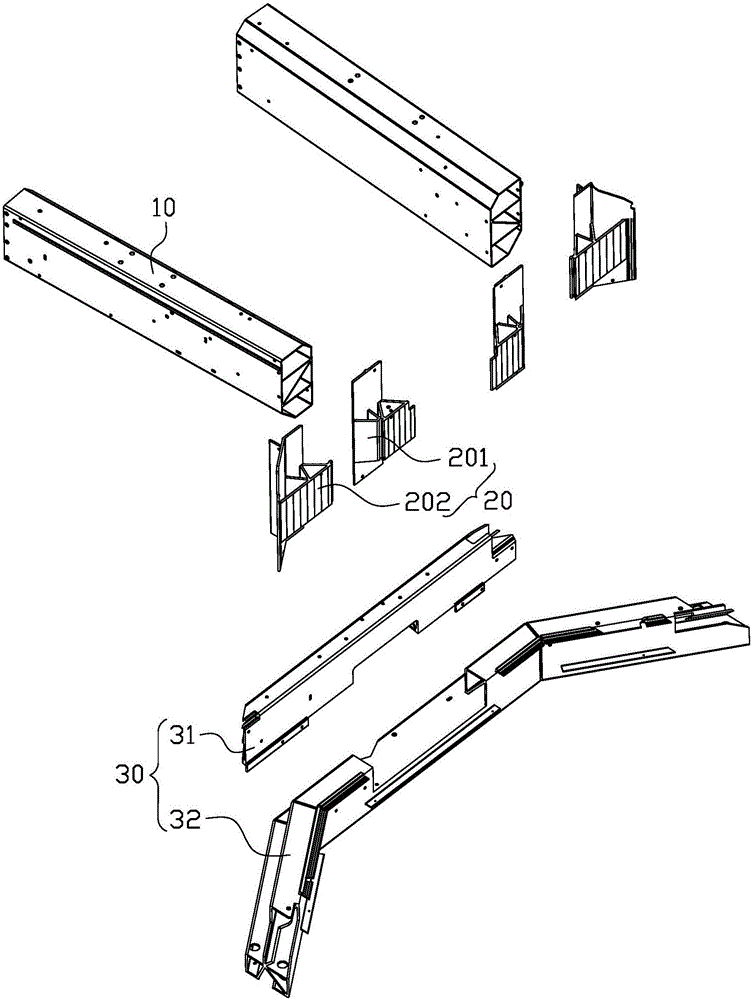

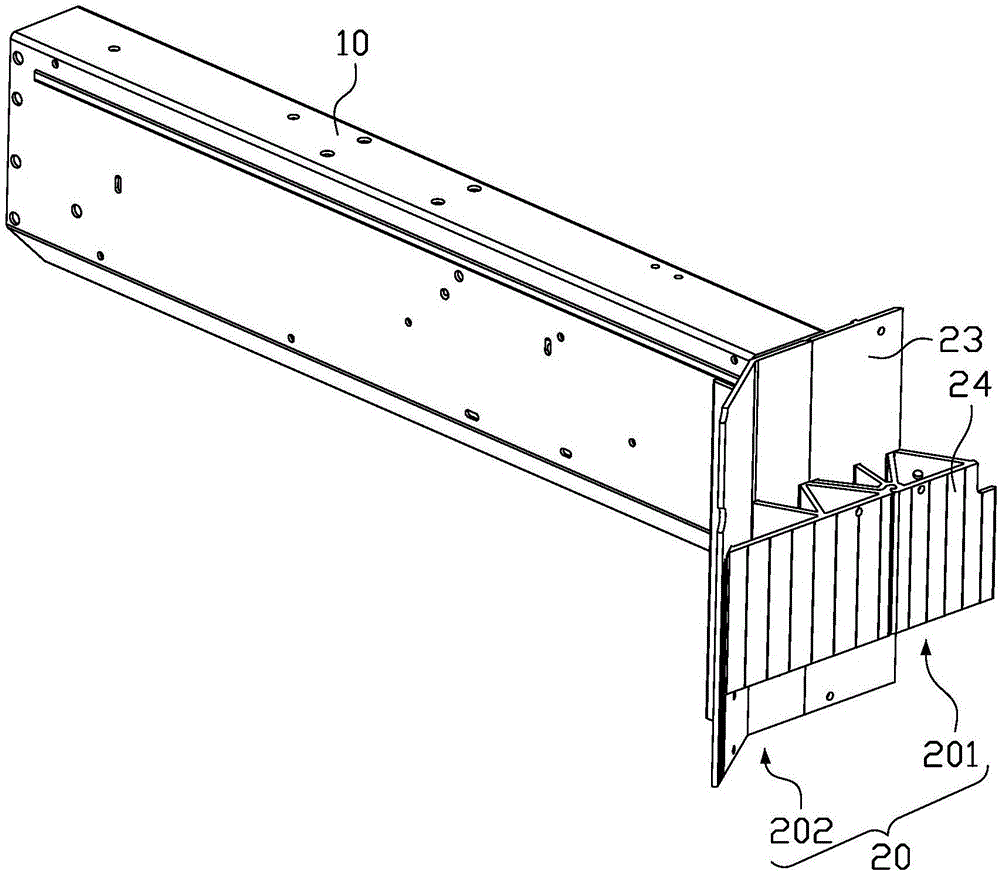

Connecting structure of vehicle cabin longitudinal beam and front wall cross beam

ActiveCN106394702ALow input costIncrease productivitySuperstructure connectionsBonding processStructural engineering

The invention proposes a connecting structure of a vehicle cabin longitudinal beam and a front wall cross beam. The vehicle cabin longitudinal beam and the front wall cross beam are connected through the connecting structure; the front end of the connecting structure is glued with the left and right two side surfaces of a cabin longitudinal beam assembly; and the back end of the connecting structure is glued with the front wall cross beam. The vehicle cabin longitudinal beam and the front wall cross beam adopt aluminum alloy profiles with better rigidity and strength; and profile molds are low in investment cost and high in production efficiency. The connecting structure is novel and unique in structure, realizes three-dimensional connection of the longitudinal beam and the cross beam, and adopts a structural glue bonding process; and because of the characteristics of cold bonding and hot curing of structural glue, a bonding area has no heat influence, and the strength after bonding curing is not influenced. Meanwhile, before the structural glue is not cured, the thickness of the glue is used for eliminating self manufacturing errors of parts and assembly errors among the parts, so that the manufacturing precision is improved.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +1

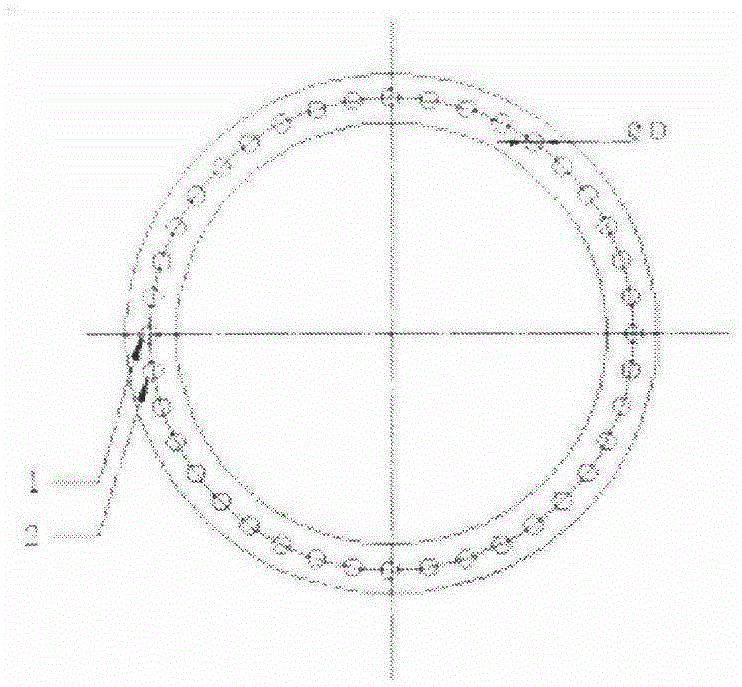

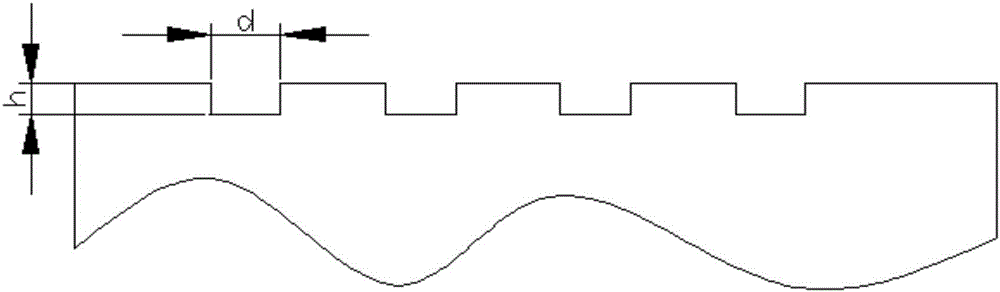

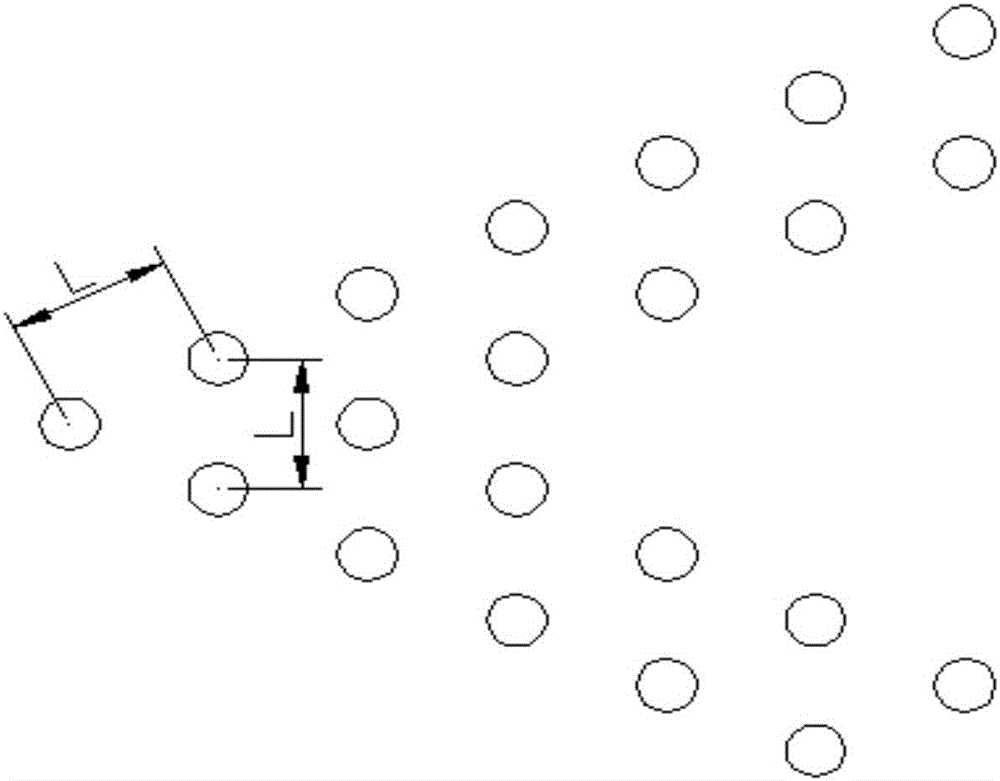

Roller bearing inner and outer ring roller path abrasion resisting structure and machining method thereof

ActiveCN106763209AFully lubricatedImprove the lubrication effectBearing componentsWave shapeEngineering

The invention provides a roller bearing inner and outer ring roller path abrasion resisting structure. Sawtooth-shaped or wave-shaped pit arrays extending in the circumferential direction are formed in an inner ring roller path and an outer ring roller path of a bearing and composed of cylindrical pits. By means of the roller bearing inner and outer ring roller path abrasion resisting structure, fluid dynamic pressure lubrication is formed on the surfaces of the roller paths of the bearing in the work state, when the roller bearing moves, lubricating oil enters a work area, a certain oil pressure is established for supporting an outer load, an oil film is formed and protects a work face, the friction coefficient is reduced, accordingly, abrasion is reduced, and the service life is prolonged. The sawtooth-shaped or wave-shaped pit arrays are constructed and distributed on the bearing in the width direction in the state that few pit arrays are arranged at the two ends, and many pit arrays are arranged in the middle, shaft end running of a lubricating agent is reduced, sufficient lubricating of the bearing in the width direction is ensured, and the lubricating performance of the bearing is improved. Meanwhile, it can be guaranteed that the abrasion resisting performance of the bearing can be improved through the cylindrical pits, it can be guaranteed that the strength and precision of the bearing are not influenced, and the integral mechanical strength, rigidity and matching precision of the bearing are guaranteed by reducing the number of the pits as much as possible.

Owner:JIANGSU UNIV OF SCI & TECH

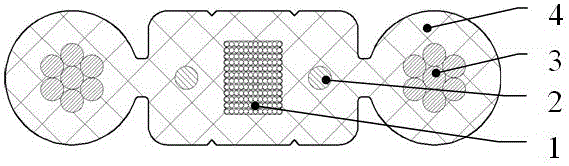

Dual self-holding optical fiber ribbon type wiring optical cable

InactiveCN105954845AImprove protectionPlay a tensile roleFibre mechanical structuresFiberEngineering

The invention discloses a dual self-holding optical fiber ribbon type wiring optical cable. The dual self-holding optical fiber ribbon type wiring optical cable comprises an optical fiber ribbon, reinforcement members, messenger wires and an oversheath. The wiring optical cable is symmetrical on the left and on the right; the optical fiber ribbon is disposed at the center of the wiring optical cable; the two messenger wires are respectively disposed at the left end and the right end of the wiring optical cable; the two reinforcement members are respectively disposed between the optical fiber ribbon and the corresponding messenger wires; and the oversheath is disposed at the peripheral side of the wiring optical cable. The wiring optical cable provided by the invention is large in cable core number, small in dimension and high in tensile strength, and can be applied to machine room wiring or fiber to the premise of indoor and outdoor buildings.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

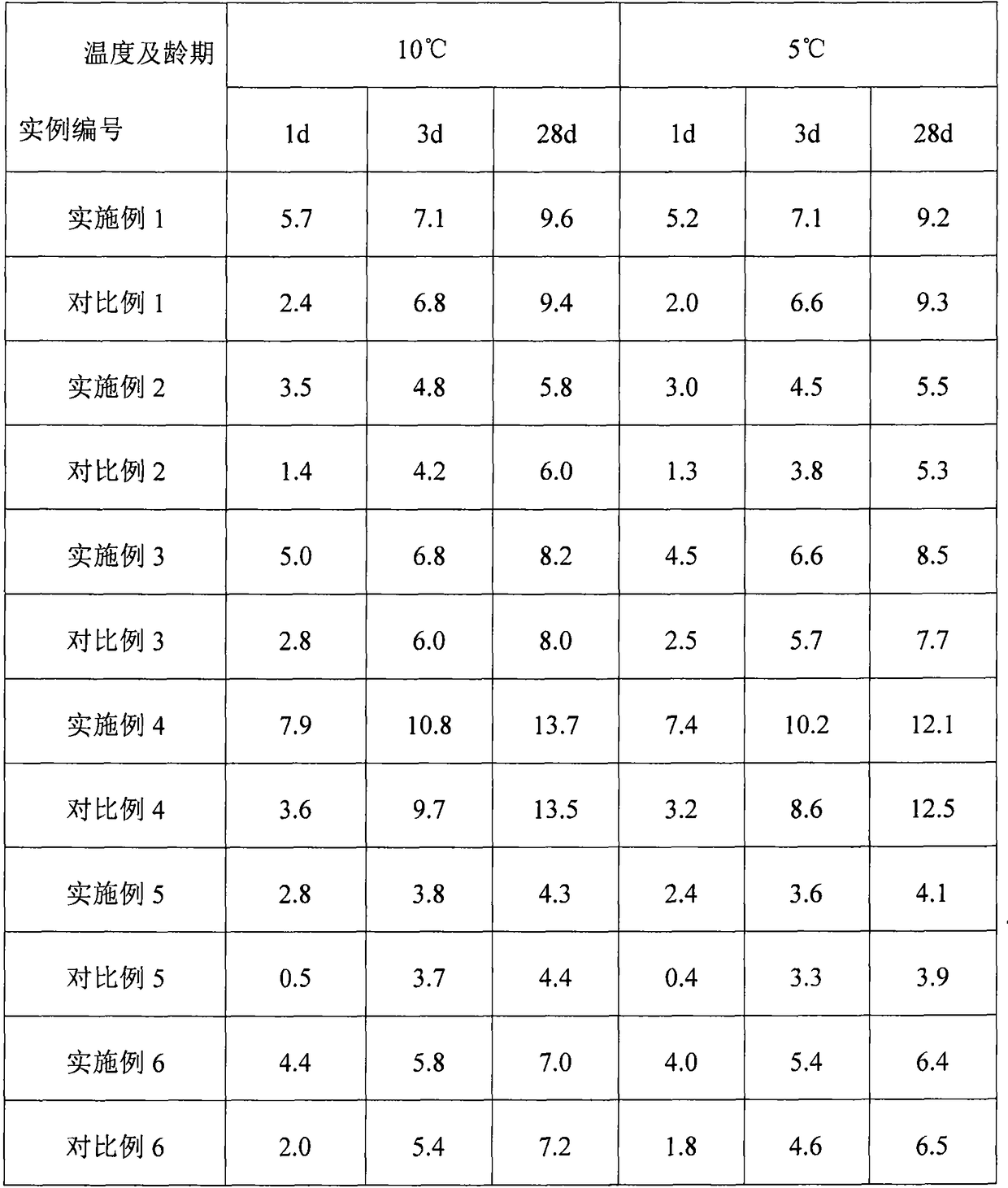

Sulphoaluminate cement foamed concrete used in low-temperature environment and preparation method thereof

PendingCN108218360AFast hydrationImprove early strengthCeramicwareFoam concreteUltimate tensile strength

The invention provides sulphoaluminate cement foamed concrete used in a low-temperature environment and a preparation method thereof. The sulphoaluminate cement foamed concrete is prepared from a sulphoaluminate cement paste body and concrete foam, wherein the sulphoaluminate cement foamed concrete is prepared by stirring the sulphoaluminate cement paste body and the concrete foam according to a volume ratio of 1 to (1 to 4) and hardening the materials. The sulphoaluminate cement paste body is prepared from the following components in parts by weight: 75 to 100 parts of sulphoaluminate cement,0 to 25 parts of fly ash, 25 to 40 parts of concrete water, 0 to 1.5 parts of water reducing agent, 0 to 100 parts of lightweight aggregates, 0.2 to 5 parts of nano-materials, and 0.1 to 0.4 part offibers, wherein the total amount sum of the sulphoaluminate cement and the fly ash is 100 parts. The preparation method disclosed by the invention is characterized in that the nano-materials are added, so that the nano-materials can quicken a hydration rate of the sulphoaluminate cement at the low temperature, so that the early strength of the foamed concrete is improved; by using the sulphoaluminate cement as a main gelatinization material, the hardening of the concrete is quick, addition of coagulant is not needed, the strength of the concrete is not affected; meanwhile, breaking of foams isalso inhibited preferably.

Owner:HENAN POLYTECHNIC UNIV

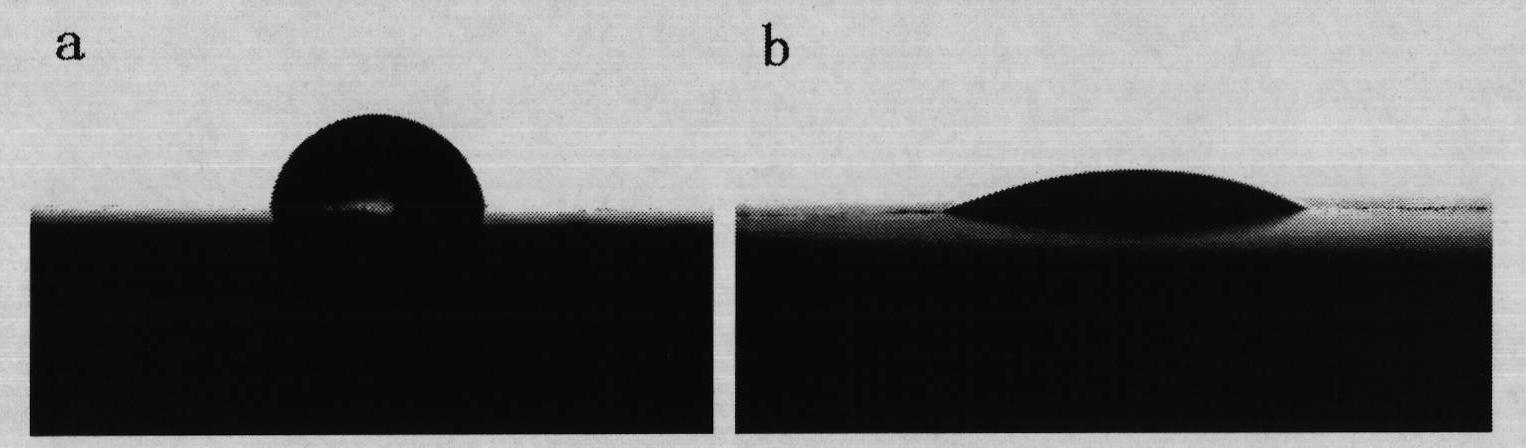

Preparation method of hydrophobic and oleophobic agent for fabric

InactiveCN107558184AReduce volatilityResilience is not affectedVegetal fibresOctadecyltrichlorosilaneEmulsion

The invention discloses a preparation method of a hydrophobic and oleophobic agent for fabric. The hydrophobic and oleophobic agent for the fabric is prepared from the following raw materials in partsby weight: 15-25 parts of resin, 2-4 parts of a silane coupling agent, 4-10 parts of silica sol, 10-20 parts of amino-silicone oil, 0.5-1 part of octadecyltrichlorosilane, 10-20 parts of lotus leaf juice, 0.5-1.5 parts of perfluorinated acrylic emulsion and 50-100 parts of ethanol. After the hydrophobic and oleophilic agent for the fabric is applied to the fabric, the hydrophobic and oleophilic contact angle of the fabric reaches 130 degrees or larger. According to the hydrophobic and oleophobic agent for the fabric, the preparation process is simple and easy to operate, the raw materials arecheap and easily available, and the hydrophobic and oleophobic agent is non-toxic, harmless, non-irritant to human bodies and low in volatility; toughness, strength and hand feeling of the finished fabric are basically not affected.

Owner:JIANGSU NEW REBA TECH CO LTD

Method for modifying steel surface of ship body by plasma at normal pressure

The invention belongs to the technical field of plasma surface processing and relates to a method for modifying the steel surface of a ship body by a plasma beam, which is to directly accomplish the modification of the steel surface of the ship body by one step of dry-process modification. The method comprises: aiming a spray gun for plasma modification at normal pressure at a steel workpiece part of the ship body to be processed, moving the spray gun at a level which is 10 to 20 millimeters above the surface of a workpiece at a constant speed and parallelly relative to the workpiece, spraying the plasma beam onto the surface of the steel workpiece of the ship body in a normal-pressure, normal-temperature and open environment, and performing the normal-temperature plasma modification of the surface of the steel workpiece of the ship body, wherein the plasma is one or more of the air, argon, nitrogen or functional gas which may be the mixed gas of ammonia gas, oxygen, silane gas, siloxane gas and acrylic acid and methylacrylic acid vapor. The process is simple, the flow is short, the controllability is high, the automation is high, the energy consumption is low, the industrial production is easy to realize, and the environment pollution is light.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Environment-friendly flame-retardant coating glue and finishing technology

The invention discloses environment-friendly flame-retardant coating glue. The environment-friendly flame-retardant coating glue comprises the following components in parts by weight: 30-32 parts of crystalline phase II ammonium polyphosphate, 6-8 parts of a fullerene nanocarbon material, 5-6 parts of polydimethylsiloxane, 3-4 parts of modified polysiloxane, 8-9 parts of methylbenzene, 1-2 parts of an organosilicone emulsion, 0.3-0.5 part of gamma-aminopropyltriethoxysilane, 0.3-0.5 part of gamma-glycidyl ether oxypropyl trimethoxysilane, 1-2 parts of fumed silica, 2-3 parts of tris(2,4-di-tert-butylphenyl) phosphite and 1-2 parts of n-tributyl phosphate. The invention further discloses a finishing technology using the environment-friendly flame-retardant coating glue. The environment-friendly flame-retardant coating glue uses low-price and easily-obtained raw materials, and is non-irritant to a human body; the toughness, the strength and hand feel of finished environmentally-friendlyflame-retardant coated fabric are basically unaffected, the finished environmentally-friendly flame-retardant coated fabric is excellent in flame retardance and washable, and the operation is simple.

Owner:YANCHENG INST OF TECH

Vinyl ester resin for fiber glass-reinforced plastic mold and preparation method thereof

The invention discloses vinyl ester resin for a fiber glass-reinforced plastic mold and a preparation method thereof. The vinyl ester resin is prepared from the following components in part by weight: 100 parts of epoxy resin, 15-20 parts of unsaturated monobasic acid, 0.1-0.3 part of catalyst, 0.03-0.06 part of polymerization inhibitor, 70-80 parts of styrene and 2-3 parts of alpha- vinyltoluene. The preparation method comprises the following steps of: feeding the epoxy resin in a reactor and raising the temperature to be 70-90DEG C; adding the catalyst and the polymerization inhibitor by stirring; continuously raising the temperature to be 105-115DEG C; dropping the unsaturated monobasic acid; after dropping, reacting at the temperature until the acid value of a reaction system is smaller than 20mgKOH / g; reducing the temperature to be 70-100DEG C and adding the styrene and the alpha-vinyltoluen; and fully stirring, cooling to the ambient temperature and filtering. The vinyl ester resin disclosed by the invention has shrinking percentage of less than or equal to 0.5 percent and is suitable for manufacturing high-grade fiber glass-reinforced plastic molds.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Square tube bending method and fabricated bent square tube

The invention discloses a square tube bending method. According to the square tube bending method, a square tube comprises a first wall body, a second wall body, a third wall body and a fourth wall body which are connected in sequence; a notch is formed in the square tube; a left tube body is arranged on the left side of the notch; a right tube body is arranged on the right side of the notch; the notch comprises a first opening, a second opening and a third opening; the first opening is formed in the first wall body; the second opening is formed in the second wall body; the third opening is formed in the fourth wall body; the square tube is folded towards the direction far away from the third wall body till the first opening, the second opening and the third opening are all closed and are all welded and fixed; and the angle between the left tube body and the right tube body is set to the required bending angle. The three surfaces of the square tube are cut to form the openings according to the design requirements; force is then applied, the surface, which is not cut but remained, of the square tube can be bent till the openings are overlapped, thereby the required angle is achieved; and then, the other three surfaces are welded, so that the strength of the whole square tube can be prevented from being influenced, any angle can be achieved, and thus the welding quality can be improved. The invention further discloses a fabricated bent square tube.

Owner:ZHEJIANG CFMOTO POWER CO LTD

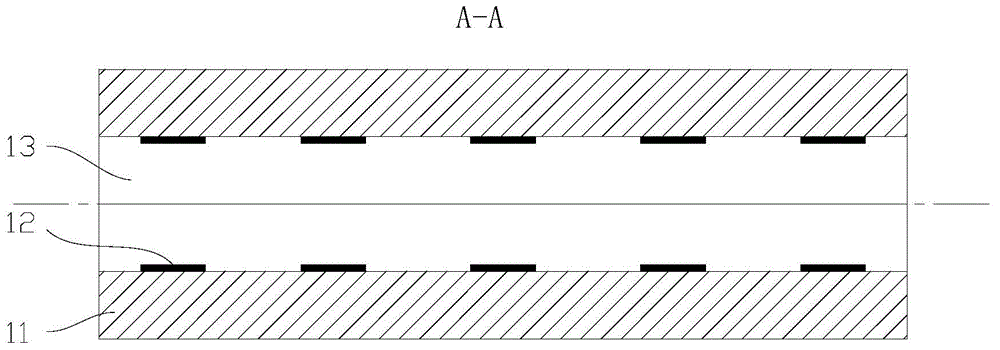

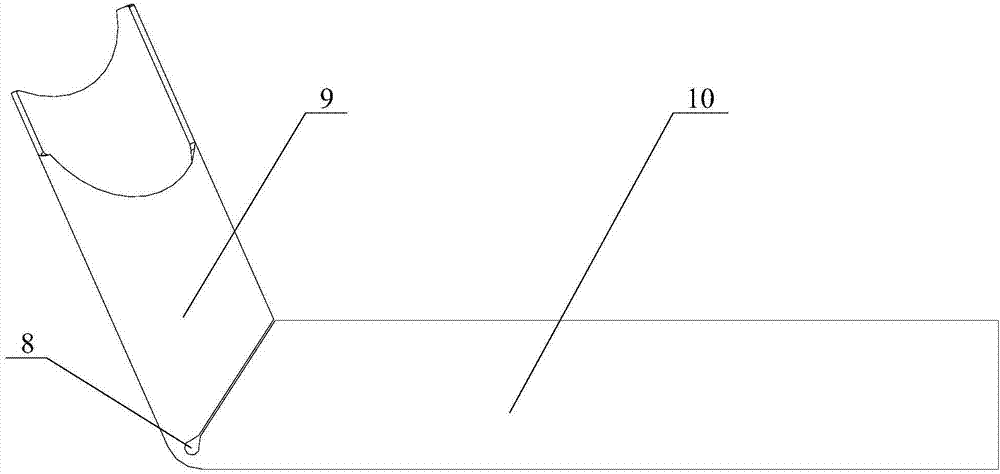

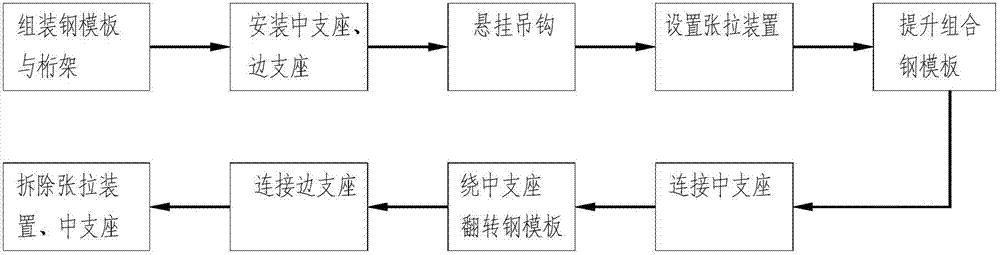

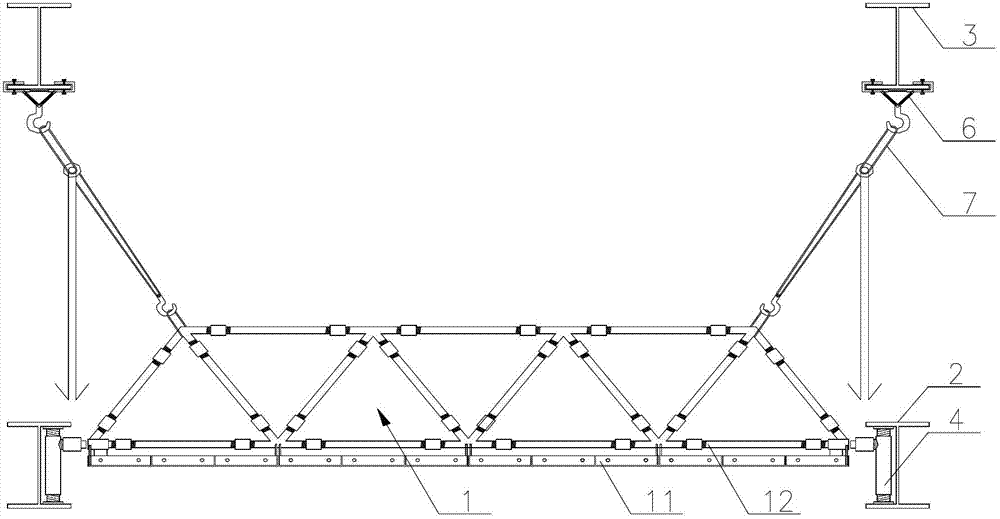

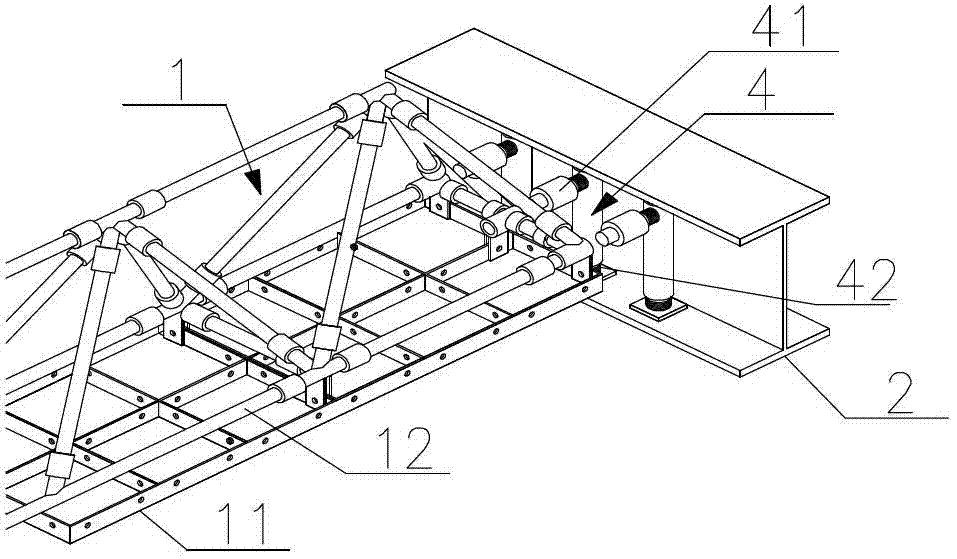

Self-supporting combined steel template construction method

ActiveCN102787717AReduce construction costsFast constructionForms/shuttering/falseworksFalseworkSystem construction

The invention relates to a multi-story and high-rise mixed structure building system construction technology, and aims to provide a self-supporting combined steel template construction method. The method comprises the following steps of: integrally and inversely assembling a self-supporting combined steel template on the ground surface or a platform, and lifting the inverse self-supporting combined steel template to a specified position through a tensioning device; connecting the inverse self-supporting combined steel template with a middle supporting seat though a horizontal connecting rod, and integrally overturning the inverse self-supporting combined steel template into place around a middle supporting seat horizontal connecting rod under the action of self-gravity; realizing connection through a side supporting seat horizontal connecting rod; and during construction of a self-supporting combined steel template of a next independent unit, circularly performing the construction steps. Compared with a construction method for erecting full framing scaffolding, the method has the advantages that the template construction cost is lowered greatly, the construction speed is increased greatly, and the site construction environment is improved remarkably.

Owner:HANGZHOU HENGDA STEEL STRUCTURE

Environment-friendly non-stick pan surface treatment process

ActiveCN108309023AIncrease surface areaIncreased micro-roughnessCooking-vessel materialsLaser beam welding apparatusMicroporous materialMaterials science

The invention discloses an environment-friendly non-stick pan surface treatment process. The treatment process comprises the following steps of 1), molding to form a microporous layer; 2), using a laser for scanning on the surface of a pan blank to form a plurality of microporous structures to obtain the microporous layer; 3), spraying a non-stick coating on the surface of the microporous layer, wherein the microporous structures are filled with the non-stick coating. The treatment process adopts a laser micro-porous forming technology for scanning the surface of the pan blank to form the dense and slender microporous structures to obtain the microporous layer, so that the superficial area of the pan blank is increased by folds, the microscopic roughness of the surface of the pan blank isimproved, when the non-stick coating is directly sprayed on the surface of the microporous layer, the microporous structures are filled with the coating to greatly increase the contact area between the non-stick coating and the microporous layer to improve the adhesion of the non-stick coating.

Owner:ZHEJIANG SANHO KITCHENWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com