Method for modifying steel surface of ship body by plasma at normal pressure

A technology of atmospheric pressure plasma and plasma, which is applied in the field of plasma surface treatment, can solve problems such as complicated process and difficulty in large-scale application, and achieve the effects of short process, low environmental pollution and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

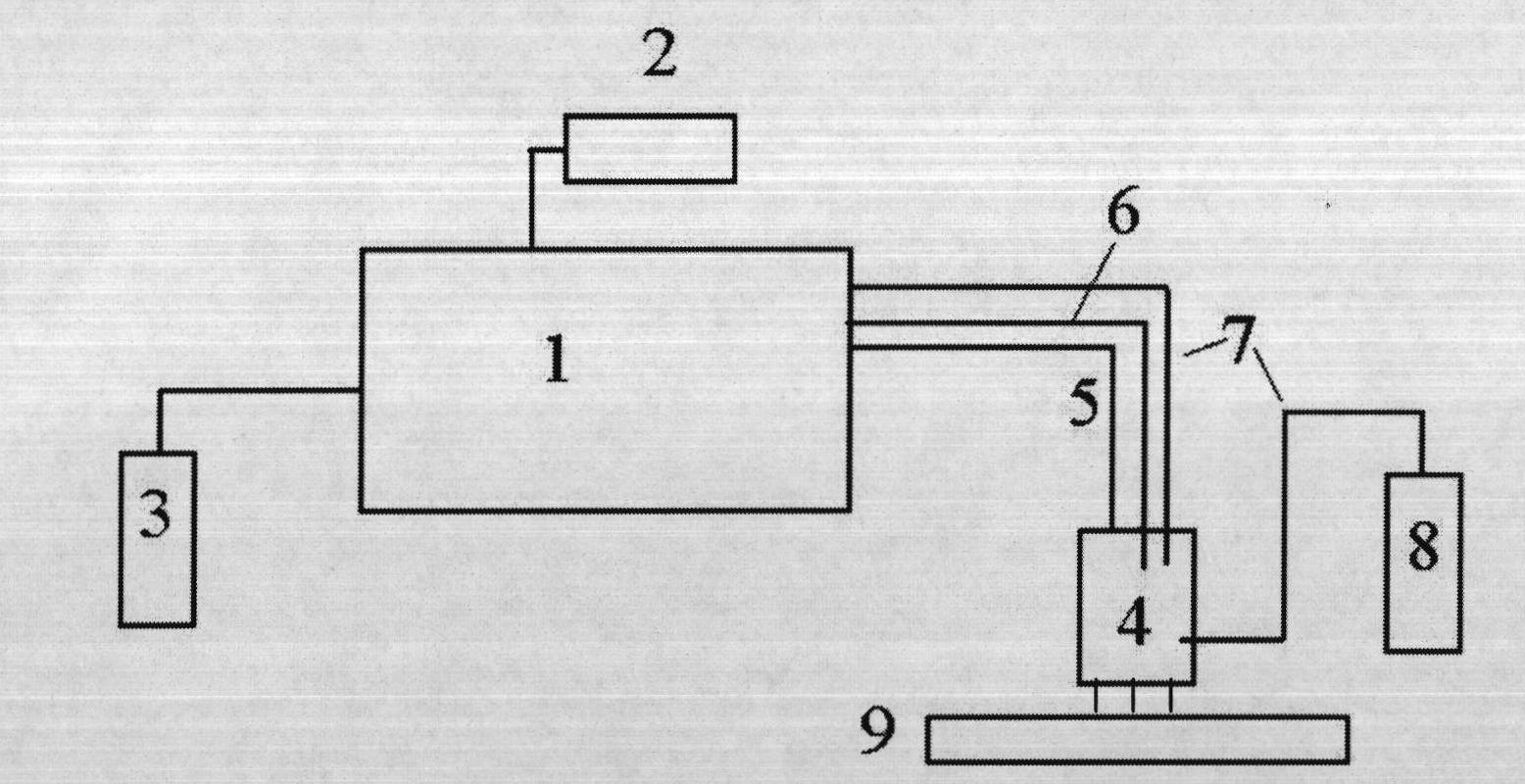

[0008] Further description will be given below through the embodiments and in conjunction with the accompanying drawings.

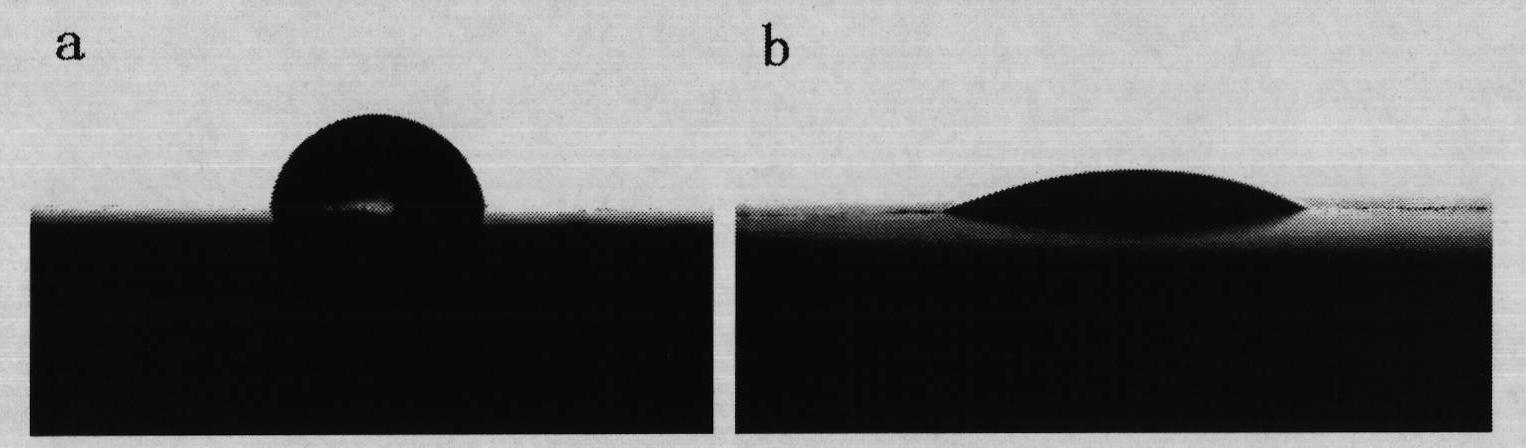

[0009] This embodiment adopts dry modification, and the modification of the hull steel surface is directly completed in the next step under atmospheric pressure, room temperature and open environmental conditions; first, the spray gun of the atmospheric pressure plasma processing equipment is aimed at the hull steel workpiece to be processed; The spray gun of the pressure plasma processing equipment moves at a constant speed relative to the workpiece at a distance of 10-20mm from the surface of the workpiece. Under normal pressure and an open environment, the plasma beam is sprayed onto the surface of the workpiece. The processing power is 300W-700W and the travel speed is 0.1-10m. / min, carry out atmospheric pressure plasma modification treatment on the surface of the workpiece; the plasma is selected from one or more of air, argon, nitrogen or functional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com