Method for engraving miniature two-dimensional code in glass laser

A glass laser, two-dimensional code technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

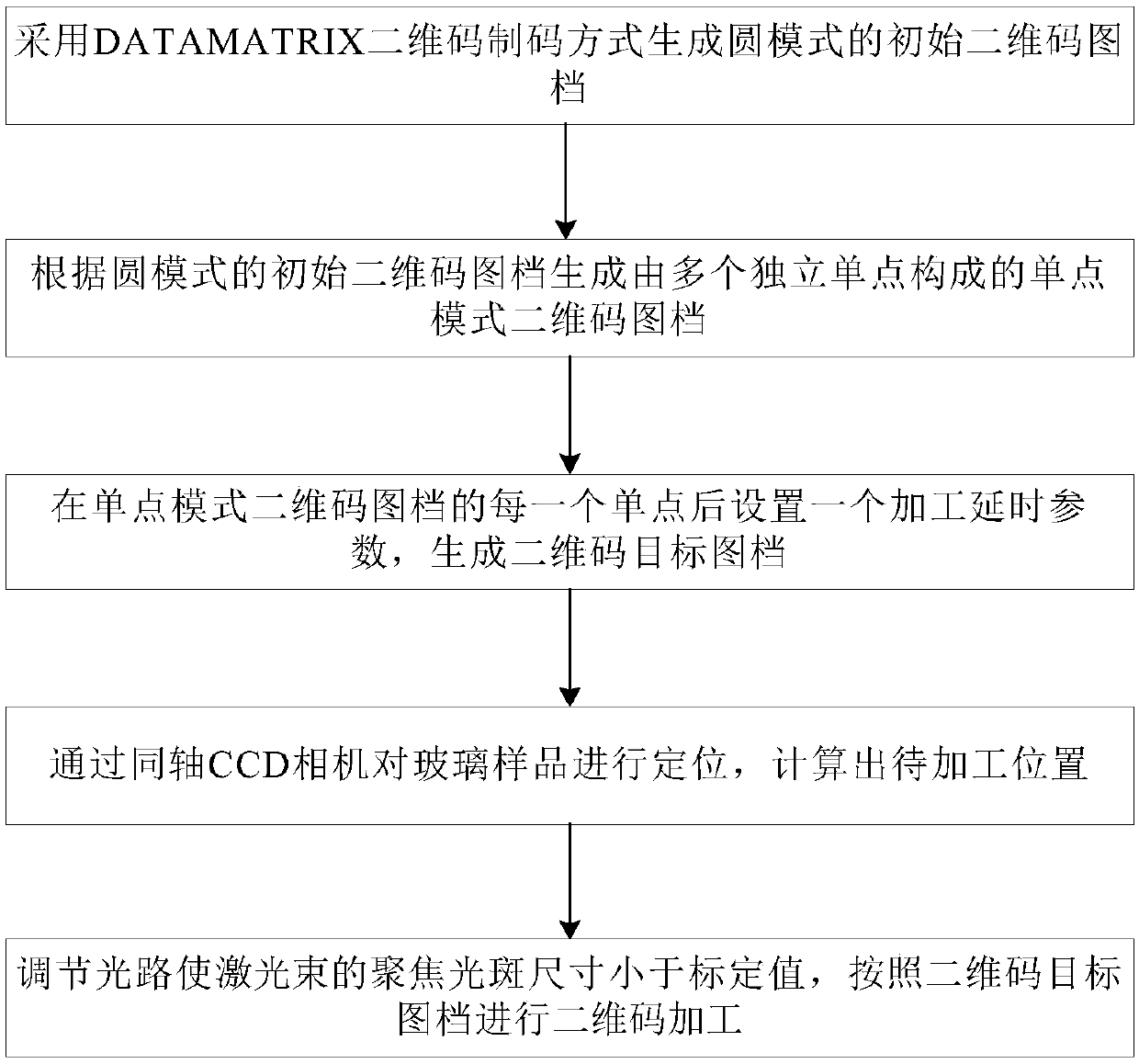

[0031] Such as figure 1 As shown, a method for engraving a miniature two-dimensional code in glass laser comprises the following steps:

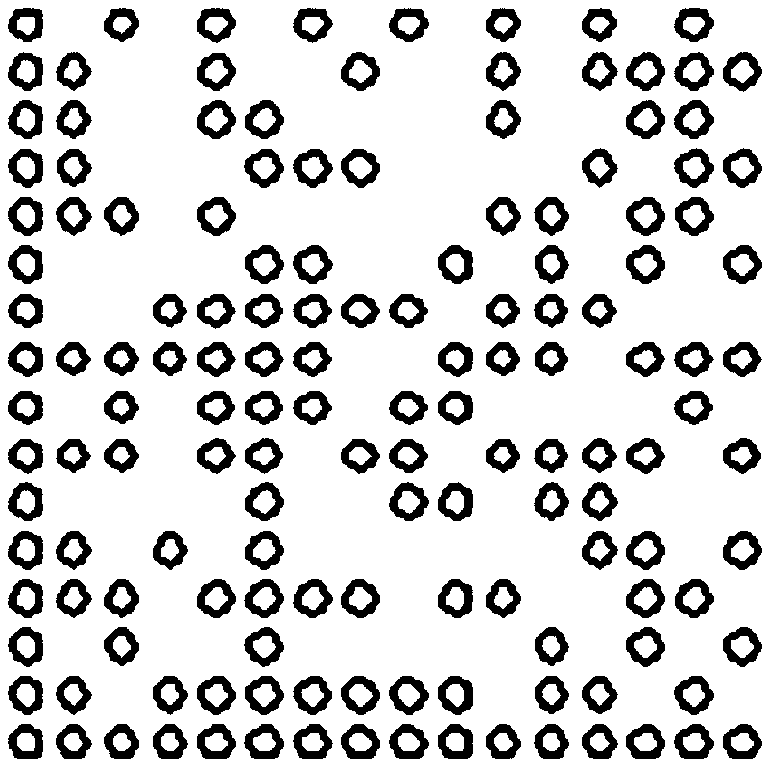

[0032] Step 1: Use the DATAMATRIX two-dimensional code system to generate the initial two-dimensional code image file of the circle pattern. Such as figure 2 As shown, the initial two-dimensional code image file of the circle mode is a whole generated by the software Ezcad through the DATAMATRIX two-dimensional code coding method. Its size is 0.10*0.10mm and contains no less than 20 characters (such as 12345678900123456789).

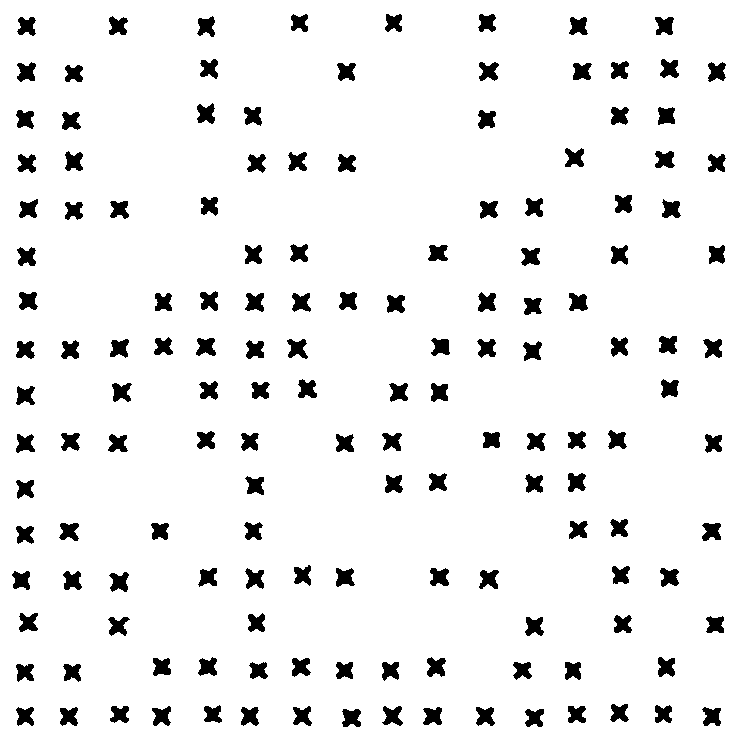

[0033] Step 2: Generate a single-point pattern two-dimensional code image file composed of multiple independent single points according to the initial two-dimensional c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com