Regenerable cyclic absorption flue gas desulfurization technology

A technology of desulfurization process and absorption method, which is applied in the field of flue gas desulfurization process of renewable cyclic absorption method, can solve the problems of increasing processing capacity, system difficulty, high energy consumption, etc., reduce circulation amount and loss, improve desulfurization efficiency, solve The effect of large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

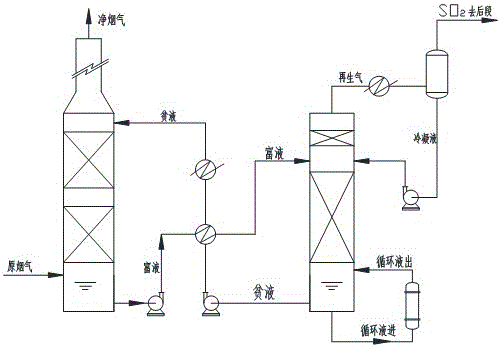

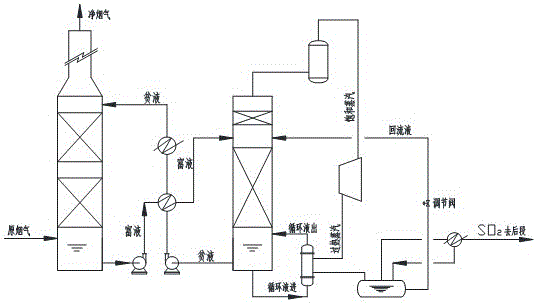

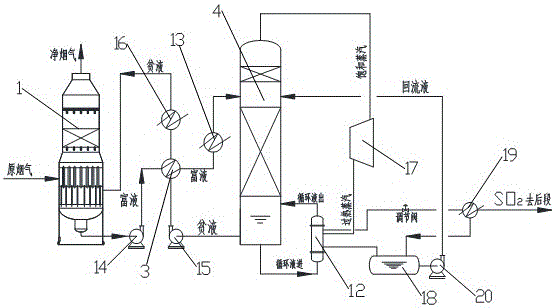

Image

Examples

Embodiment 1

[0048] This embodiment relates to the renewable cycle absorption flue gas desulfurization process of iron and steel and non-ferrous metallurgy sintering flue gas, including the following process steps:

[0049] A: The flue gas from the coal-fired power plant boiler is cooled to 40°C after dedusting and washing, and then sent to the bubble tower 1;

[0050] B: Coal-fired power plant boiler flue gas is sent into the inlet space 7 of the bubble tower 1, and the bubble pipe 8 guides the flue gas into the liquid layer of the absorbent liquid phase area at the lower part of the absorption tower at a certain pressure for 250mm to form bubbles In the bubbling area, the flue gas fully contacts and reacts with the absorbent, and the SO in the flue gas 2 After the impurities are absorbed, the clean flue gas reaches the upper outlet space 9 through the riser pipe 11, and then is emptied by the absorption tower chimney after passing through the washing section and the demisting section;

...

Embodiment 2

[0055] This embodiment relates to a renewable cyclic absorption flue gas desulfurization process for flue gas of a coal-fired power plant boiler, including the following process steps:

[0056] A: The flue gas from iron and steel and non-ferrous metallurgy sintering is dedusted and washed, then cooled to 45°C, and then sent to bubble tower 1;

[0057] B: The sintering flue gas of iron and steel and non-ferrous metallurgy is sent into the inlet space 7 of the bubble tower 1, and the bubble pipe 8 guides the flue gas into the liquid layer of the absorbent liquid phase area at the lower part of the absorption tower for 200mm at a certain pressure, forming a bubble In the bubble area, the flue gas in the bubble area fully contacts and reacts with the absorbent, and the SO in the flue gas 2 After the impurities are absorbed, the clean flue gas reaches the upper outlet space 9 through the riser pipe 11, and then is emptied by the absorption tower chimney after passing through the wa...

Embodiment 3

[0062] This embodiment relates to a renewable cyclic absorption flue gas desulfurization process for industrial furnace flue gas, including the following process steps:

[0063] A: After dust removal and washing, the flue gas from the industrial kiln is cooled to 45°C, and then sent to the bubble tower 1;

[0064] B: Industrial furnace flue gas is sent into the entrance space 7 of the bubble tower 1, and the bubble pipe 8 guides the flue gas into the liquid layer of the absorbent liquid phase area at the lower part of the absorption tower for 200mm at a certain pressure, forming a bubble area , the flue gas in the bubbling area fully contacts and reacts with the absorbent, the SO in the flue gas 2 After the impurities are absorbed, the clean flue gas reaches the upper outlet space 9 through the riser pipe 11, and then is emptied by the absorption tower chimney after passing through the washing section and the demisting section;

[0065] C: The rich liquid is boosted from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com