Chemical fiber plus material normal pressure plasma treatment method

A technology of atmospheric pressure plasma and treatment method, applied in the field of physical treatment and chemical treatment of surface cross-linking and grafting technology, can solve the problems of poor moisture absorption and perspiration performance, high dyeing temperature, and poor air permeability of chemical fiber fabrics, and achieve different strength The effect of impact, simple operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

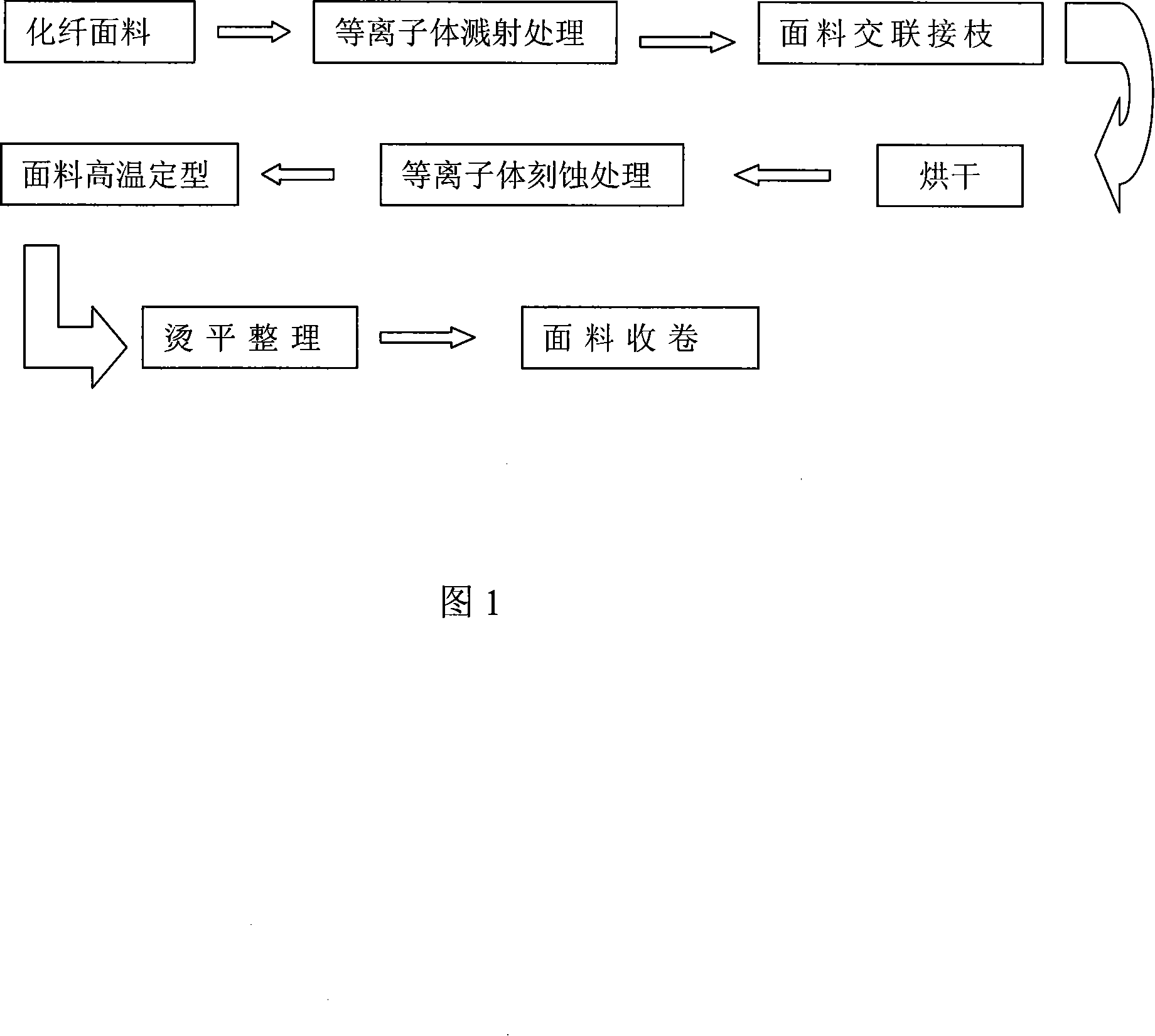

[0015] Referring to the accompanying drawings, the present invention specifically adopts the following steps:

[0016] 1) Fabric surface sputtering: make chemical fiber fabrics pass through atmospheric pressure plasma equipment; plasma is composed of a large number of free electrons and ions, which collide with atoms and molecules in the gas to generate ionization, and the resulting gaseous substances contain Metastable and excited state atoms, molecules, and ions react chemically with inert gases such as helium, argon, and oxygen, effectively remove impurities by sputtering on the surface of chemical fiber fabrics, and introduce hydrophilic groups and free radicals, thereby improving the hydrophilic and moisture-absorbing properties of chemical fiber fabrics.

[0017] 2) Surface cross-linking and grafting: the chemical fiber fabrics with hydrophilic and hygroscopic properties that have been treated by plasma surface sputtering, and then cross-linked and surface-grafted by acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com