Natural water erosion face ceramic decoration split tile and its production method

A technology of splitting bricks and natural water, applied in the direction of pavement, road, covering/lining, etc., can solve the problems of poor artistic effect, unnatural surface of splitting bricks, etc., achieve beautiful appearance, brick body strength is not affected, production The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

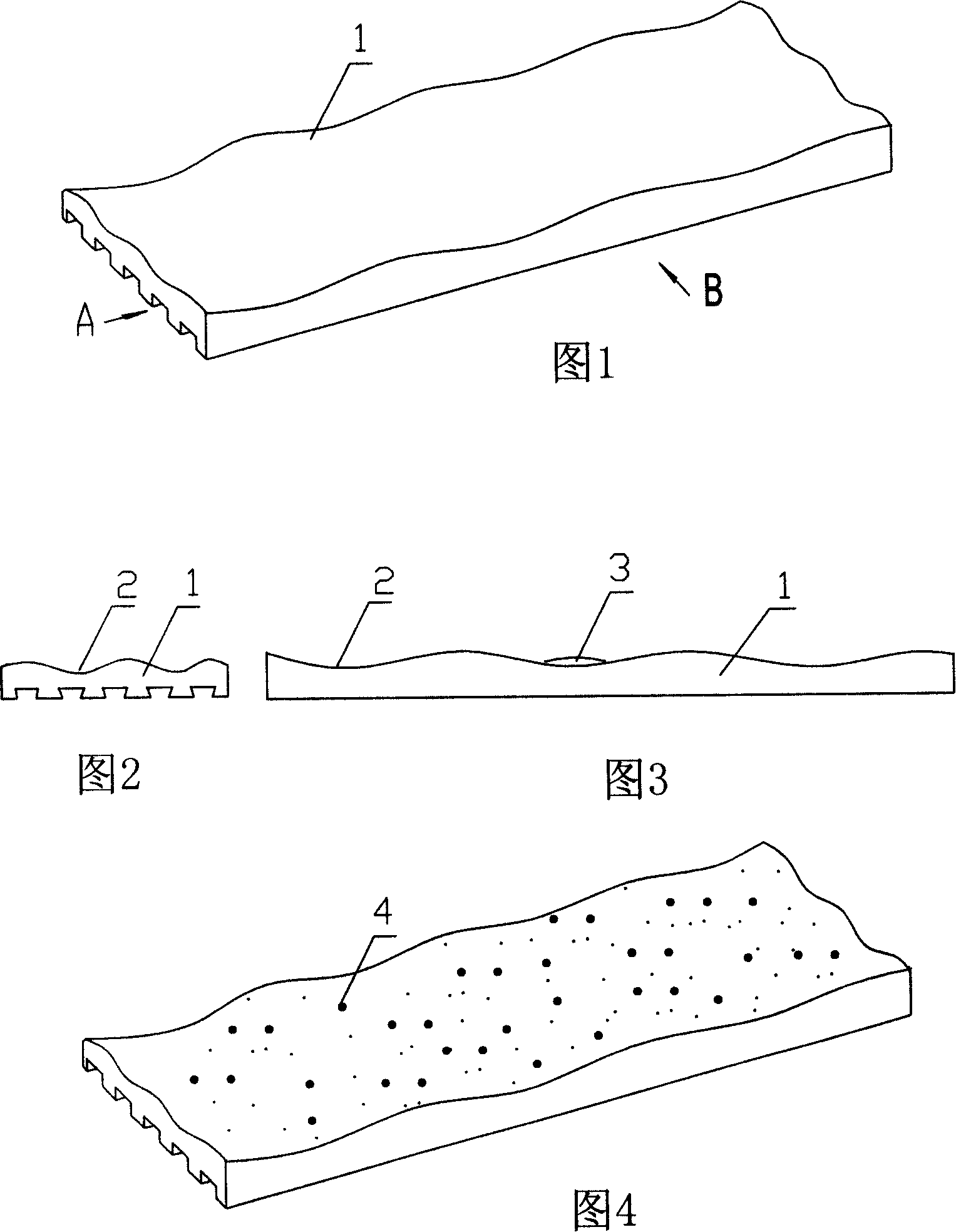

[0016] A natural water-eroded surface ceramic decorative split-away brick. Including the split brick adobe 1, the surface of the split brick is a water-eroded surface, that is, the brick surface has different depths, uneven pits or arcs or natural round pits formed by water erosion and scour (see Figures 1 to 3), the depth of the uneven pits on the brick surface or the height of the arc is 0.1 to 3mm, in the figure, 2 represents the pit, and 3 represents the raised arc or small round surface.

[0017] The green body 1 includes a split brick body made of the same color or different color green blocks.

Embodiment 2

[0019] A natural water-eroded surface ceramic decorative split brick with particles on the surface. Its basic structure is the same as that of Example 1, the difference is that there are some random and irregularly distributed hard particles 4 (see Figure 4) on the surface of the brick, and the particle size of the hard particles is between 10 mesh and 20 mesh .

[0020] The shape of the outer surface of the natural water-eroded surface ceramic decorative split brick of the present invention is not limited to the forms shown in Figs. 1-4.

Embodiment 3

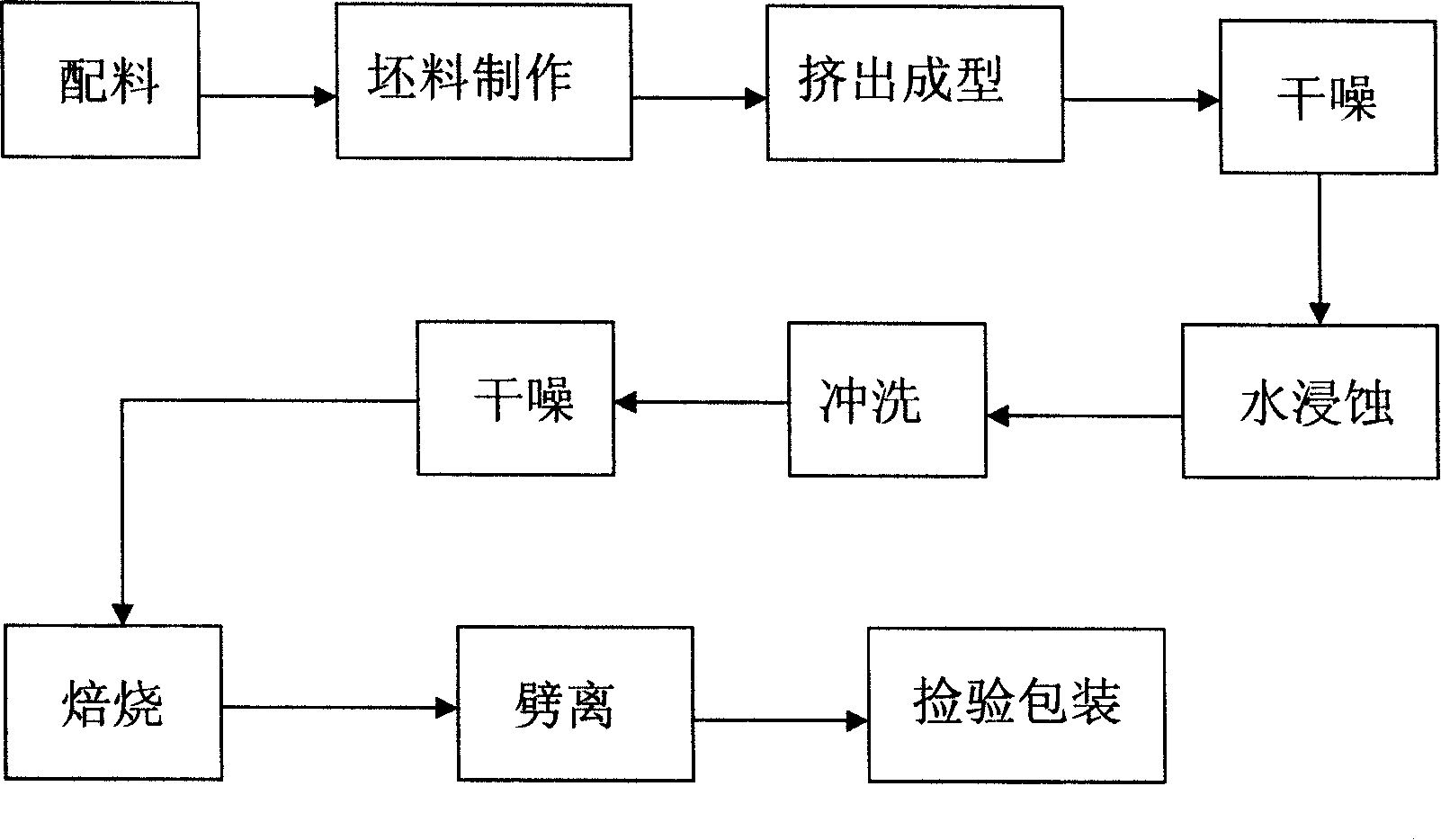

[0022] A kind of natural water-eroded face pottery decorative splitting brick production method, it comprises the following steps (see Figure 5 ):

[0023] A. Ingredients: According to the ratio of 45% to 70% of plastic raw materials, 5% to 25% of barren raw materials, and 10% to 30% of flux raw materials, the plastic raw materials are selected from clay or china clay or mixtures thereof; the barren raw materials are Use quartz or clinker that is crushed from waste products fired in the furnace, or a mixture thereof; the raw material of the flux is feldspar or talc, calcite, dolomite or a mixture thereof;

[0024] B. Blank preparation:

[0025] The first method: wet grinding, pressing (filtering) and vacuum mud refining: weigh all kinds of raw materials according to the proportion, put them into the ball mill, add water ball mill for 1-8 hours, control the moisture content of the mud at 30-65%, and control the fineness of the mud Sieve the remaining 1-20% in 200 mesh, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com