A kind of preparation method of in-situ crystallization catalytic cracking catalyst

An in-situ crystallization and catalytic cracking technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as a large increase in white powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

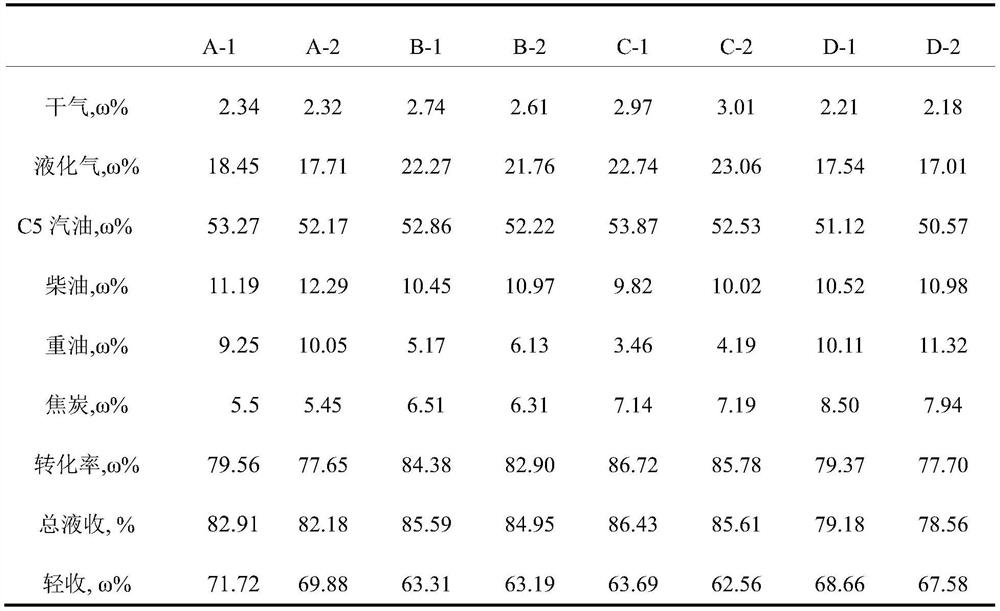

Examples

Embodiment 1

[0051] Preparation of in-situ crystallization product: the directing agent is prepared by mixing 308g of water glass and 189g of peralkali sodium metaaluminate, and standing at 35°C for 15h. 10 kg of kaolin and water were prepared into a slurry with a solid content of 35%, and 500 g of sodium silicate was added as a dispersant for spray molding. The obtained spray soil balls were roasted at 940°C for 2h. Stir 1kg of roasted high clay balls with 1050mL of 10% sodium hydroxide solution, heat up to 85°C for 120min, then add 200g of directing agent, heat up to 93°C, statically crystallize for 25h, filter, wash and dry.

[0052] Preparation of in-situ crystallization catalyst: Mix 500g of in-situ crystallization product with 100g of ammonium chloride, 100g of ammonium sulfate and 3000g of distilled water, adjust the pH value to about 3.5 with hydrochloric acid solution, heat up to 85°C for 2 hours, filter, and filter cake Wash with 2000g of distilled water to obtain an exchange sa...

Embodiment 2

[0054] Preparation of in-situ crystallization products: the directing agent is prepared by mixing 312g of water glass and 208g of peralkali sodium metaaluminate, and standing at 33°C for 20h. 10 kg of kaolin and water were prepared into a slurry with a solid content of 27%, and 1000 g of aluminum sol was added as a dispersant for spray molding. The obtained sprayed soil balls were roasted at 920°C for 6 hours to obtain high soil balls, and roasted at 600°C for 6 hours to obtain partial earth balls. Stir 800g of high-soil balls and 200g of partial-soil balls after roasting with 950mL of 18% sodium hydroxide solution, and heat up to 70°C for 180 minutes, then add 220g of directing agent, heat up to 96°C, stir and crystallize for 24h, filter , wash and dry.

[0055] Preparation of in-situ crystallization catalyst: mix 500g of in-situ crystallization product with 300g of ammonium nitrate, 75g of lanthanum chloride and 3000g of distilled water, adjust the pH value to about 4.0-4.5...

Embodiment 3

[0057] Preparation of in-situ crystallization product: the directing agent is prepared by mixing 153g of water glass and 98g of peralkali sodium metaaluminate, and standing at 34°C for 32h. 10 kg of kaolin and water were prepared into a slurry with a solid content of 40%, and 500 g of aluminum sol was added as a dispersant for spray molding. The obtained sprayed soil balls were roasted at 1030°C for 1.5h to obtain high soil balls, and roasted at 850°C for 1.5h to obtain partial earth balls. Stir 650g and 350g of high earth balls after roasting with 750mL of 20% sodium hydroxide solution, and heat up to 100°C for 45min, then add 180g of directing agent, heat up to 85°C, stir and crystallize for 36h, filter , wash and dry.

[0058] Preparation of in-situ crystallization catalyst: Mix 500g of in-situ crystallization product with 300g of ammonium nitrate, 25g of lanthanum chloride, 25g of lanthanum nitrate and 3000g of distilled water, adjust the pH value to about 4.0-4.5 with hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com