Preparation method of thermal-insulation fireproof material

A technology of thermal insulation and fireproof materials and materials, applied in the field of thermal insulation and fireproof materials, can solve the problems of high cost and high energy consumption, and achieve the effects of low density, low thermal conductivity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

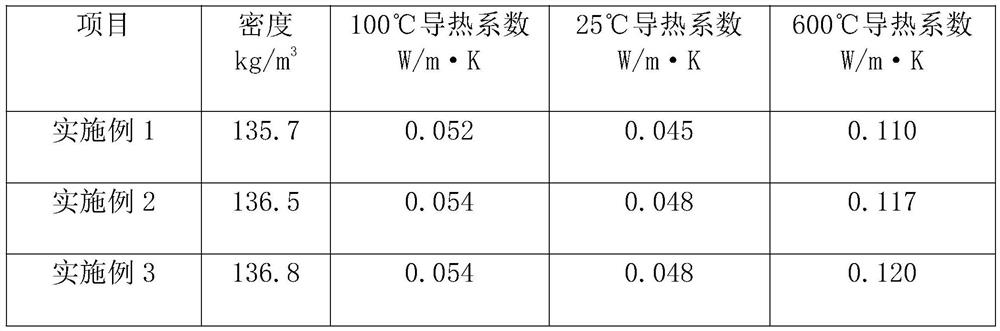

Embodiment 1

[0019] (1) 222kg of fly ash, 100kg of quicklime and 4830kg of water were mixed and put into the reactor, and reacted at 220° C. for 2 hours to obtain the reacted material.

[0020] (2) Cool the reacted material to 90°C, then add 5kg of pulp fiber, mix and stir for half an hour, filter water in the mixing tank to obtain a formed wet filter cake, then dry in a tunnel kiln at a temperature of 100°C for 6 hours, Xonotlite is obtained after palletizing.

[0021] In this example, 222kg of fly ash contains 41.22% of glassy silica, 100kg of quicklime contains 91.2% of calcium oxide, and the liquid-solid ratio is 15:1.

Embodiment 2

[0023] (1) 227kg of fly ash, 100kg of quicklime and 5886kg of water were mixed and put into the reactor, and reacted at 210°C for 3 hours to obtain the reacted material.

[0024] (2) Cool the reacted material to 90°C, then add 5kg of pulp fiber, mix and stir for half an hour, filter water in the mixing tank to obtain a formed wet filter cake, then dry in a tunnel kiln at a temperature of 100°C for 6 hours, Xonotlite is obtained after palletizing.

[0025] In this example, 227kg of fly ash contains 40.10% glassy silica, 100kg of quicklime contains 91.0% of calcium oxide, and the liquid-solid ratio is 18:1.

Embodiment 3

[0027] (1) 222kg of fly ash, 100kg of quicklime and 6440kg of water were mixed and put into the reactor, and reacted at 200°C for 4 hours to obtain the reacted material.

[0028] (2) Cool the reacted material to 90° C., then add 5 kg of pulp fiber, mix and stir for half an hour, filter water to obtain a wet filter cake, and then dry at 100° C. for 6 hours to obtain xonotlite.

[0029] In this example, 222kg of fly ash contains 41.05% glassy silica, 100kg of quicklime contains 91.15% of calcium oxide, and the liquid-solid ratio is 20:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com