Decomposition method of phosphate rock

A technology of phosphate rock and phosphoric acid, applied in chemical instruments and methods, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of low phosphorus yield, etc., to improve phosphorus recovery rate, improve decomposition rate and phosphorus recovery rate, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

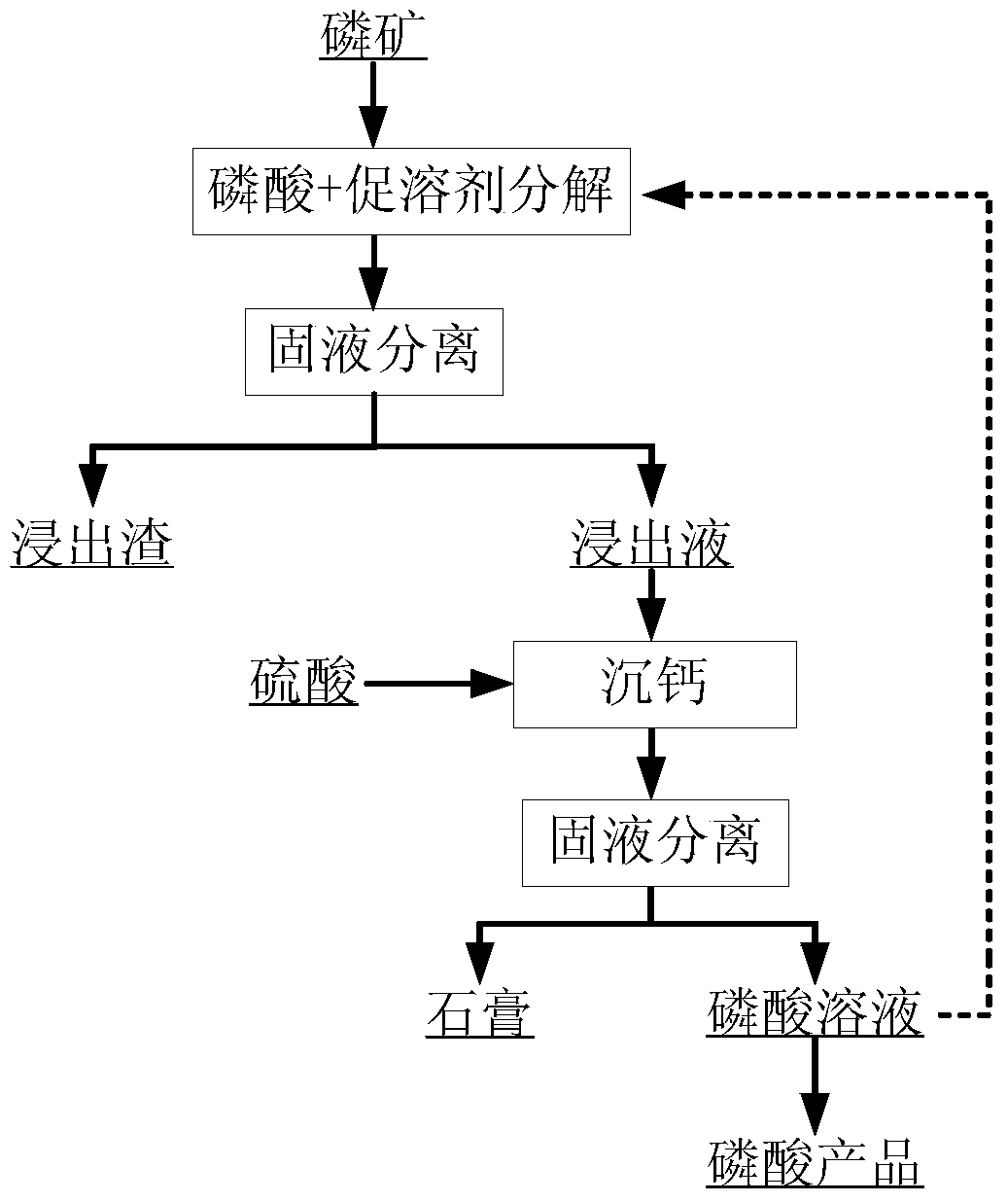

Method used

Image

Examples

Embodiment 1

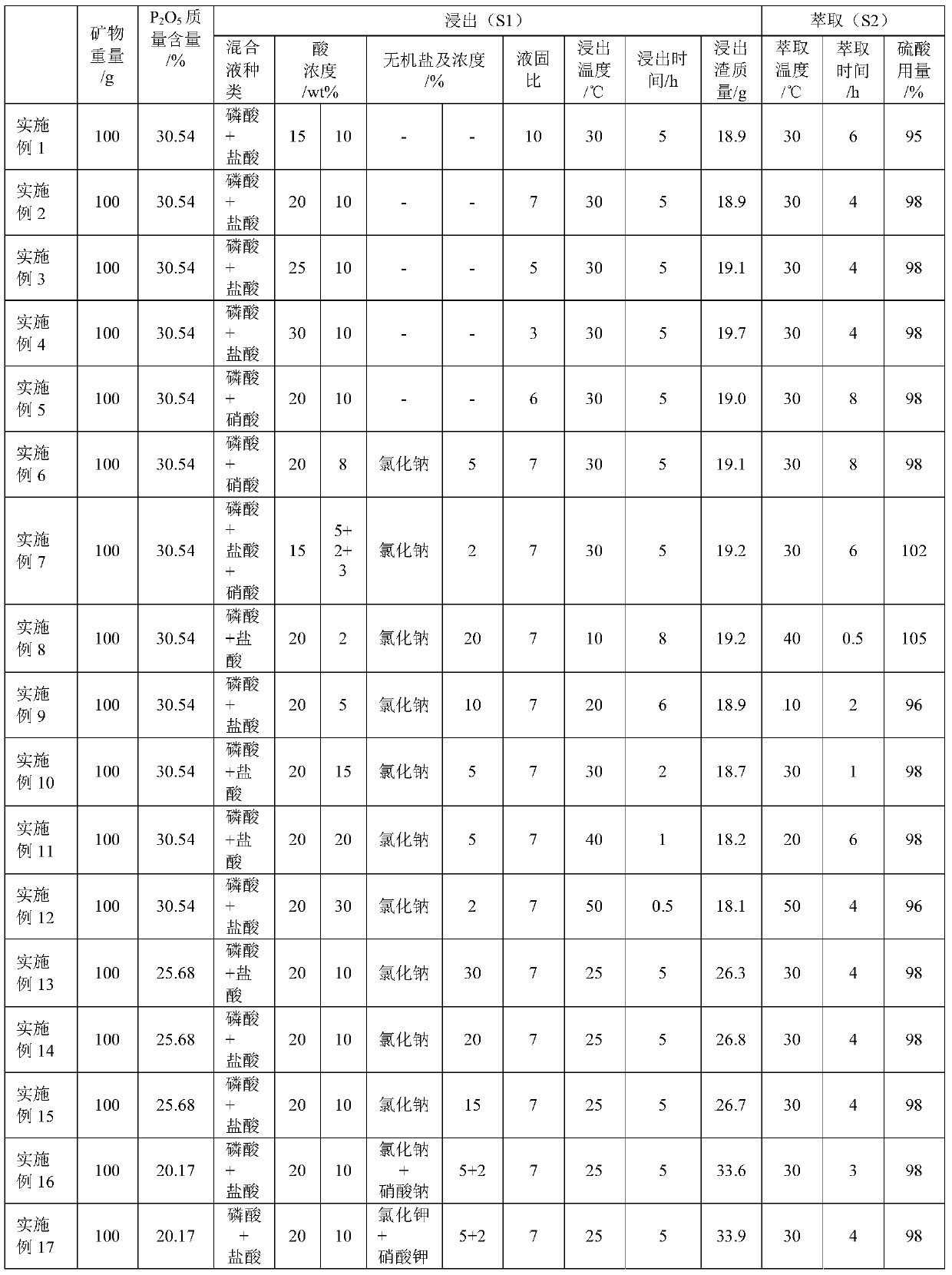

[0038] Taking 100g of phosphate rock as raw material, adopting a mass concentration of 15% phosphoric acid solution (in terms of P 2 o 5 ) and a mixed solution of hydrochloric acid with a molar concentration of 10% (in terms of moles of anions) to leach the phosphate rock, control the liquid-solid ratio of the system to 10:1, react at 30°C for 5 hours, and obtain the leachate and Leach residue.

[0039] The leaching solution is extracted with 90wt% sulfuric acid to obtain phosphogypsum and phosphoric acid solution. Wherein, the extraction temperature is 30° C., the extraction time is 6 h, and the amount of sulfuric acid is 95% of the stoichiometric amount.

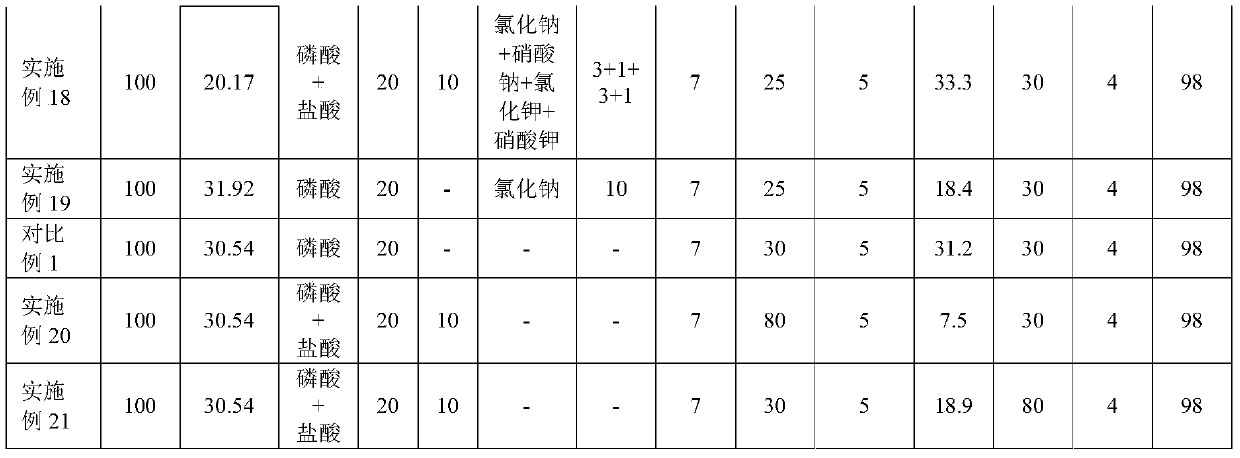

Embodiment 2 to Embodiment 21 and comparative example 1

[0041] Example 2 to Example 21 and Comparative Example 1 were decomposed according to the decomposition conditions shown in Table 1, using the same steps as in Example 1 to decompose phosphate rock.

[0042] Table 1:

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com