Method for selectively leaching rare earth elements from red mud

A rare earth element, selective technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylates, etc., can solve problems such as failure to be effectively recycled, and achieve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

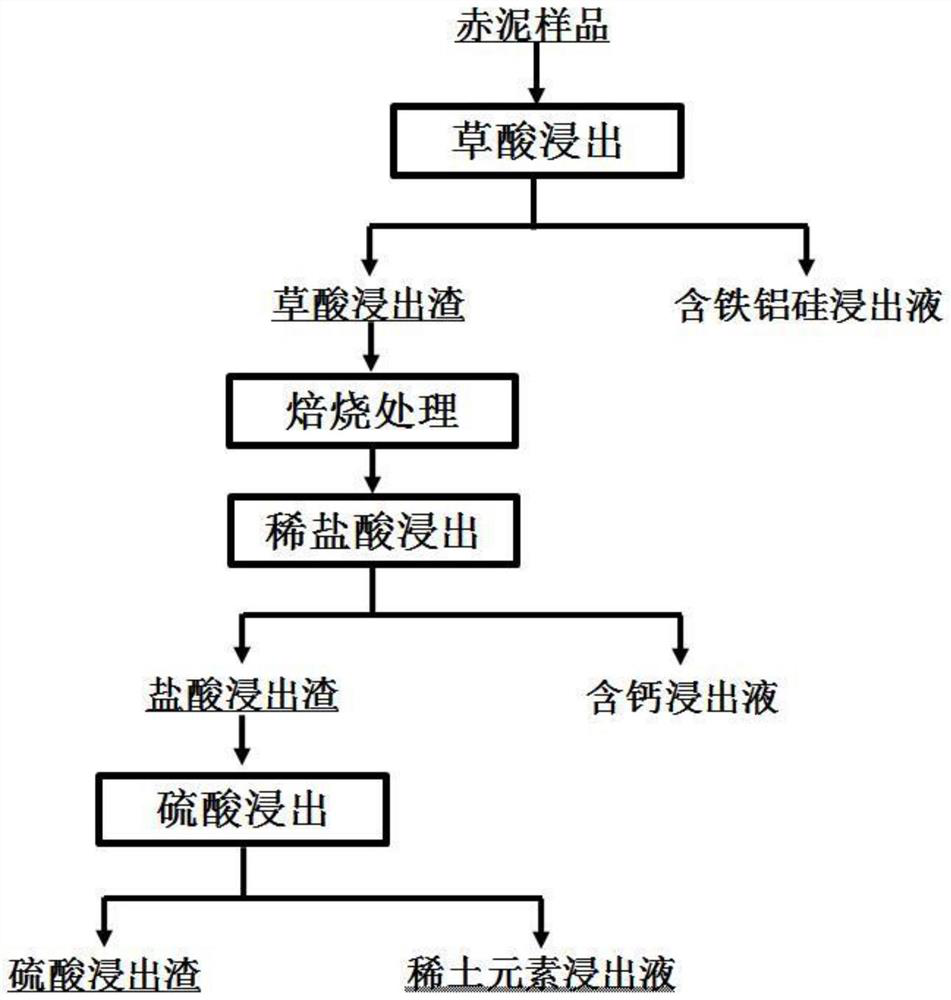

Method used

Image

Examples

Embodiment 1

[0031] Dry and grind the red mud and pass through a 100-mesh sieve, weigh 50g of red mud, add 750mL of oxalic acid solution (concentration: 1mol / L), put it in a constant temperature water bath shaker and react (react at 75°C for 2h), and obtain red mud after filtration oxalic acid leaching slag and oxalic acid leaching solution; put the oxalic acid leaching slag of red mud into a muffle furnace for roasting, the roasting temperature is 520°C, and the roasting time is 0.5h. After taking it out, add 0.05mol / L diluted Hydrochloric acid, placed in a constant temperature water bath oscillator to react (reaction at room temperature for 2.5h), filtered to obtain hydrochloric acid leaching residue and hydrochloric acid leaching solution of red mud; finally add 1mol / L sulfuric acid solution (liquid-solid ratio 5mL / g), placed in a constant temperature water bath shaker at 95°C to react for 3 hours, and filtered to obtain a sulfuric acid leaching solution rich in rare earth elements.

...

Embodiment 2

[0034] Dry and grind the red mud and pass through a 100-mesh sieve, weigh 50g of red mud, add 750mL of oxalic acid solution (concentration: 1mol / L), put it in a constant temperature water bath shaker and react (react at 75°C for 2h), and obtain red mud after filtration oxalic acid leaching slag and oxalic acid leaching solution; put the oxalic acid leaching slag of red mud into a muffle furnace for roasting, the roasting temperature is 520°C, and the roasting time is 0.5h. After taking it out, add 0.05mol / L diluted Hydrochloric acid, placed in a constant temperature water bath oscillator to react (reaction at room temperature for 2.5h), filtered to obtain hydrochloric acid leaching residue and hydrochloric acid leaching solution of red mud; finally add 1mol / L sulfuric acid solution (liquid-solid ratio 10mL / g), placed in a constant temperature water bath shaker at 95°C to react for 0.5h, and filtered to obtain a sulfuric acid leaching solution rich in rare earth elements.

[0...

Embodiment 3

[0037] Dry and grind the red mud and pass through a 100-mesh sieve, weigh 50g of red mud, add 750mL of oxalic acid solution (concentration: 1mol / L), put it in a constant temperature water bath shaker and react (react at 75°C for 2h), and obtain red mud after filtration oxalic acid leaching slag and oxalic acid leaching solution; put the oxalic acid leaching slag of red mud into a muffle furnace for roasting, the roasting temperature is 520°C, and the roasting time is 0.5h. After taking it out, add 0.05mol / L diluted Hydrochloric acid, placed in a constant temperature water bath oscillator to react (reaction at room temperature for 2.5h), filtered to obtain hydrochloric acid leaching residue and hydrochloric acid leaching solution of red mud; finally add 1mol / L sulfuric acid solution (liquid-solid ratio 10mL / g), placed in a constant temperature water bath shaker at 95°C to react for 4 hours, and filtered to obtain a sulfuric acid leaching solution rich in rare earth elements.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com