Method for selectively recovering electrode powder of lithium ion battery

An ion battery and lithium recovery technology, applied in the field of selective recovery of lithium ion battery electrode powder, selective recovery of battery electrode powder, can solve the problems of low recovery rate, limited industrial application value, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

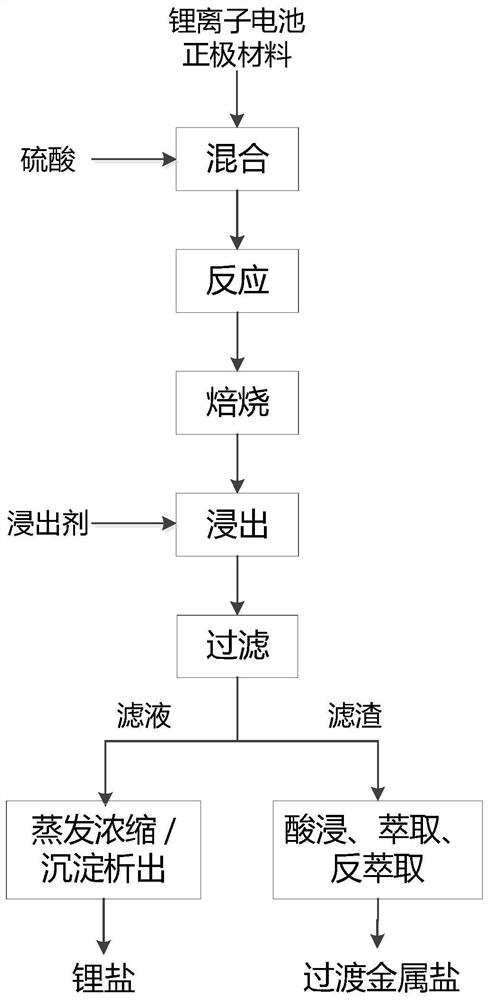

Method used

Image

Examples

Embodiment 1

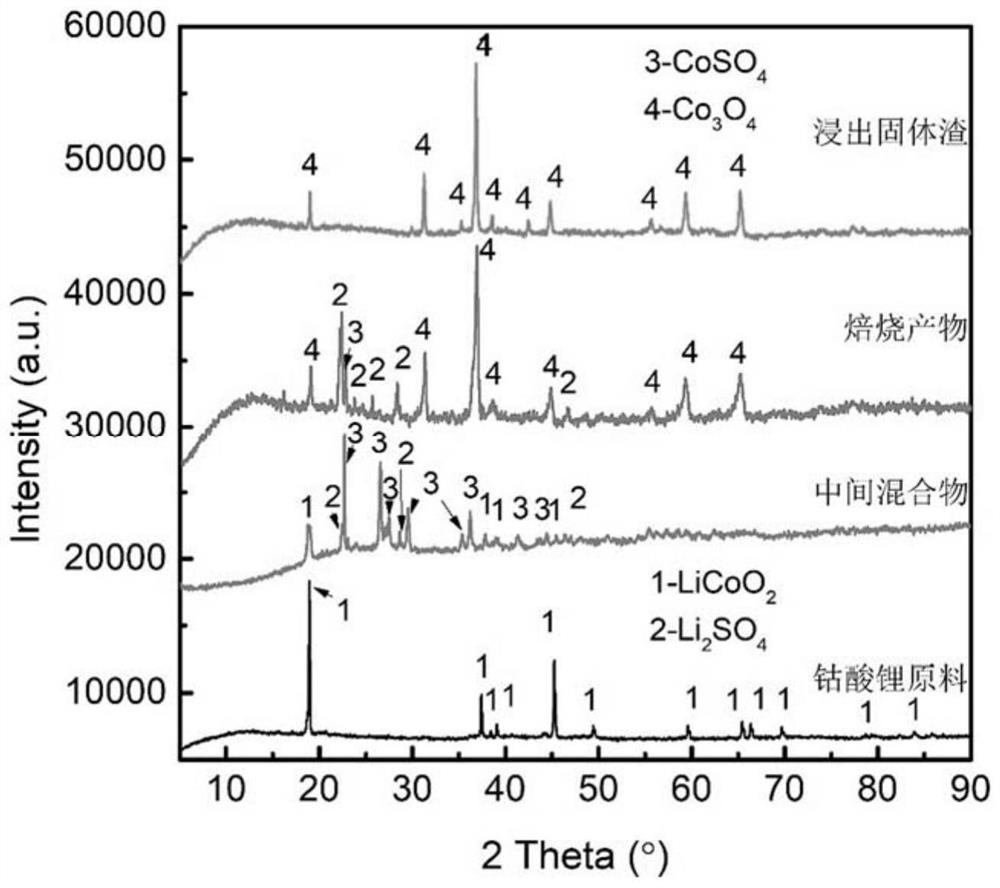

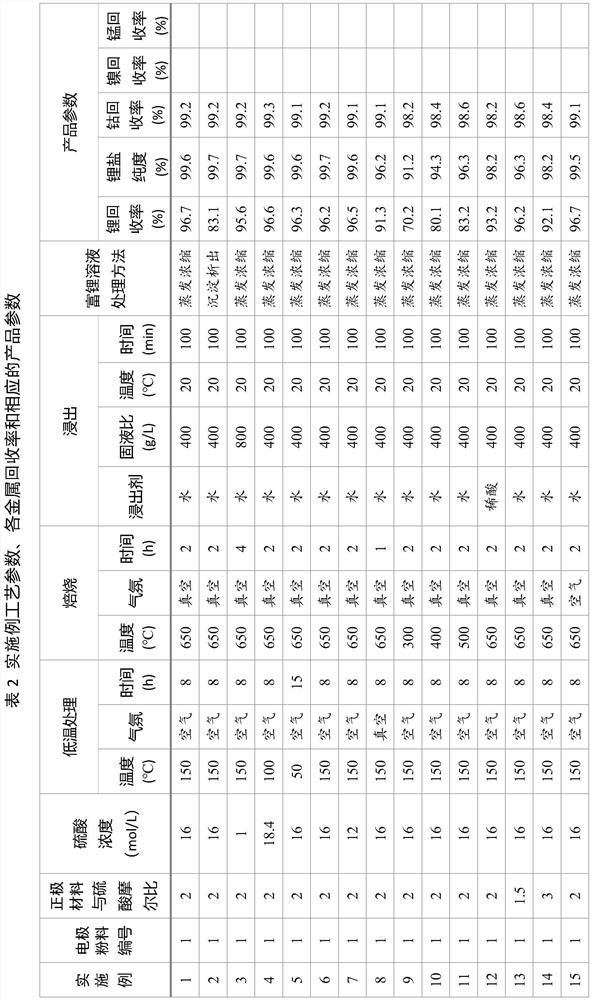

[0069] (1) The lithium-ion battery electrode material is crushed to obtain powder 1, mixed with sulfuric acid, the molar ratio of the positive electrode material to sulfuric acid is 2:1, the concentration of sulfuric acid is 16mol / L, heated to 150°C, and reacted in the air for 8h, to obtain an intermediate mixture;

[0070] (2) Calcining the mixture at 650° C. in vacuum for 2 hours to obtain the product; and

[0071] (3) The product is leached with water, the solid-to-liquid ratio is 400g / L, leached at 20°C for 20h, and separated to obtain a lithium-rich solution and solid slag.

[0072] (4) The lithium-rich solution is concentrated by evaporation to obtain lithium salt, and the solid slag is sequentially subjected to sulfuric acid leaching, extraction and stripping to obtain cobalt salt

[0073] In this embodiment, the recovery rate of lithium in step (3) is calculated to be 96.7% through detection by inductively coupled plasma emission spectroscopy (ICP-OES). According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com