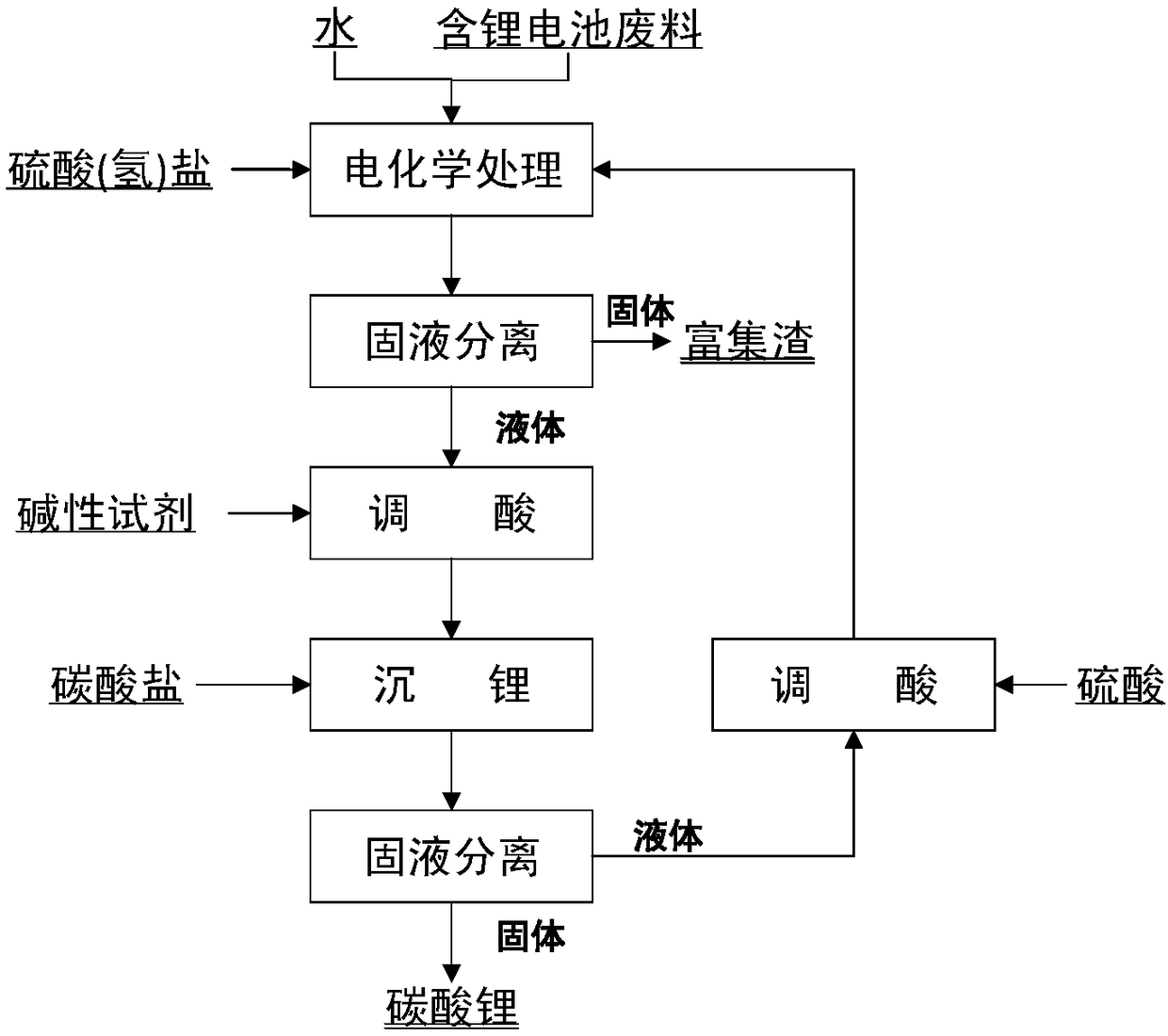

Method for recovering lithium in lithium-containing battery waste materials

A technology for lithium batteries and waste materials, applied in the direction of lithium carbonate; The effect of high recovery selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The present embodiment provides a method for reclaiming lithium in lithium-containing battery waste, the specific method is:

[0062] (1) Add 15wt% Na 2 SO 4 Mix the raw material slurry in the solution, the solid-liquid ratio is 10g / L, preheat the raw material slurry to 85°C; place the raw material slurry in a closed electrolytic cell at normal pressure, apply mechanical stirring and electrochemical field, and control the current The density is 320A / m 2 Carry out electrolysis (electrochemical treatment), stirring rate is 200rpm, react 4h, make reaction slurry; Filter and separate reaction slurry, obtain reaction enrichment slag and lithium-containing purification liquid, use ICP to analyze the content of each element in the purification liquid for analysis.

[0063] (2) adding NaOH to the lithium-containing purification solution gained in step (1) to adjust the pH of the solution is 11.5 (acid adjustment), and then adding NaOH 2 CO 3 , carry out the lithium precipi...

Embodiment 2

[0067] The present embodiment provides a method for reclaiming lithium in lithium-containing battery waste, the specific method is:

[0068] (1) Alkali leaching in NaOH solution to remove LiNi from aluminum foil in advance 0.5 co 0.2 mn 0.3 o 2 (NCM523) Add 20wt% NaHSO to positive electrode waste 4 The raw material slurry was prepared by mixing in the solution, the solid-liquid ratio was 20g / L, and the raw material slurry was preheated to 80°C; the raw material slurry was placed in a closed electrolytic cell at normal pressure, and mechanical stirring was applied, and the plate-shaped titanium sheet was used as the Anode, with carbon rod as cathode, applied electrochemical field, controlled current density to 750A / m 2 Perform electrolysis with a stirring rate of 300rpm and react for 2 hours to obtain a reaction slurry; filter and separate the reaction slurry to obtain reaction tailings and a lithium-containing purification solution, and use ICP to analyze the content of each...

Embodiment 3

[0072] The present embodiment provides a method for reclaiming lithium in lithium-containing battery waste, the specific method is:

[0073] (1) Add 10wt% NH to the lithium iron phosphate full battery waste that has been dealuminated by alkaline leaching in NaOH solution in advance 4 HSO 4 Mix the raw material slurry in the solution, the solid-liquid ratio is 25g / L, preheat the raw material slurry to 60°C; place the raw material slurry in a closed electrolytic cell at normal pressure, apply mechanical stirring and electrochemical field, and control the current The density is 100A / m 2 Perform electrolysis with a stirring rate of 400rpm and react for 10 hours to obtain a reaction slurry; separate the reaction slurry from solid to liquid to obtain reaction tailings and a lithium-containing purification solution, and use ICP to analyze the content of each element in the purification solution;

[0074] (2) adding ammoniacal liquor to adjust the pH of the solution to be 8.0 in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com