Apparatus for deep-frying food comprising reservoir for collecting condensate from vapour being discharged during deep-frying process

A steam and storage tank technology, which is applied to utensils for frying in oil, cooking utensils, household utensils, etc., can solve the problems of deposition, decreased cooling effect, and laborious removal of scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

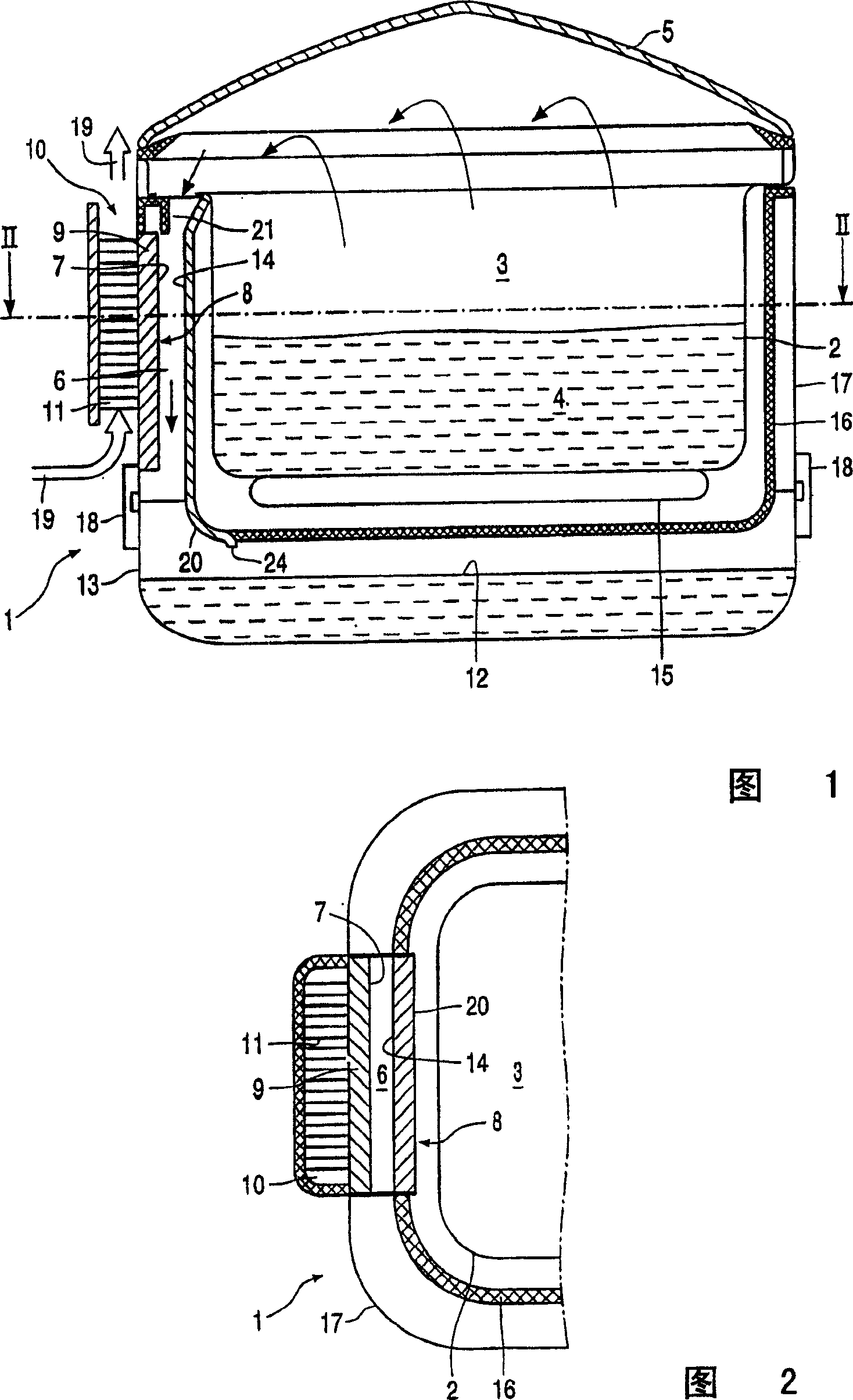

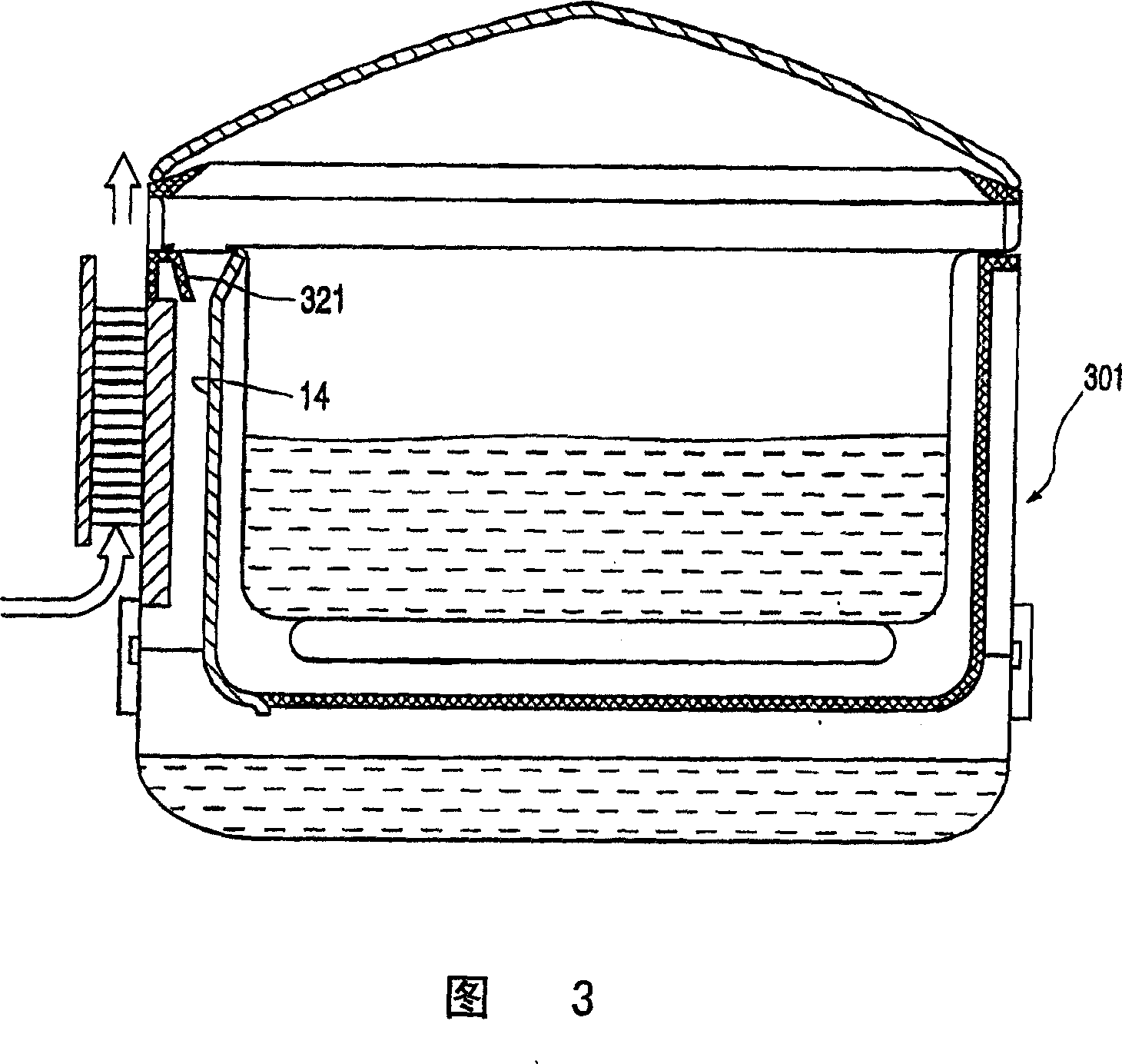

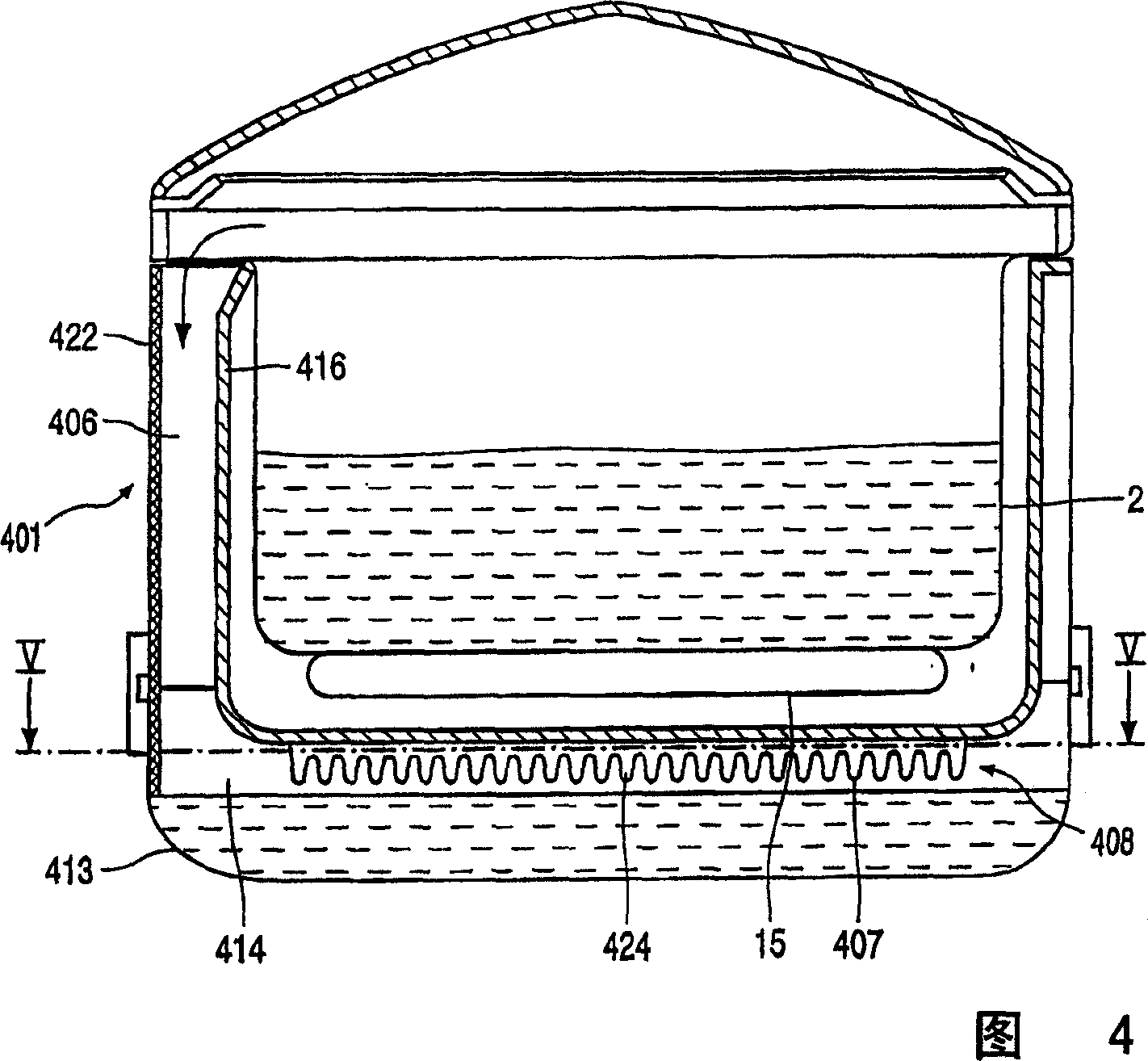

[0030] The embodiment of the deep fryer for food shown in FIGS. 1 and 2 is a tabletop deep fryer 1 . Other embodiments of the deep fryer are also possible, for example the deep fryer can be embedded in a hob.

[0031] The deep fryer 1 comprises an inner pot 2 comprising an inner space 3 containing a frying medium 4 which in use is liquid such as frying oil. Another part of the deep fryer 1 is a deep fryer basket (not shown) that can be suspended in the inner pot 2 . Such baskets are well known.

[0032] A cover 5 covering the inner pot 2 constitutes the upper boundary of the inner space 3 of the inner pot 2 . A steam discharge channel 6 protrudes from the inner space 3 , and the steam discharge channel 6 communicates with the inner space 3 .

[0033] A cooling surface 7 constituted by a surface of a heat exchanger 8 serves to cool the vapour. The heat exchanger 8 has a plate 9 made of aluminum or other heat transfer material on the side of the steam discharge channel. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com