Method for preparing lithium carbonate from lithium-containing electrode wastes

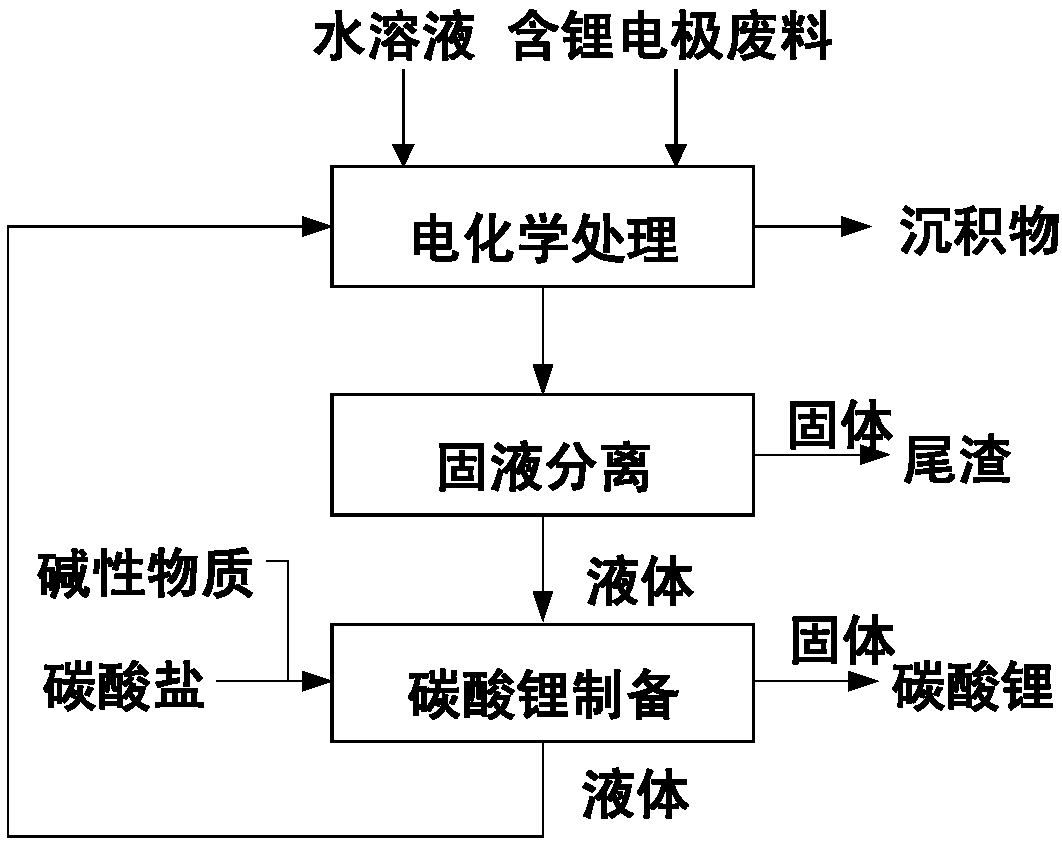

A lithium electrode and lithium carbonate technology, applied in the field of lithium carbonate preparation, can solve the problems of increasing the processing burden and energy consumption of the separation process, reducing the overall recovery rate of lithium, reducing the concentration of lithium ions, etc., and achieving the goal of simplifying leaching and selective removal Process, extraction and selective separation to promote and realize the effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The present embodiment provides a kind of method that lithium carbonate is prepared with lithium-containing electrode waste, and its concrete method is:

[0062] (1) After grinding and screening lithium nickelate waste balls (containing lithium battery waste), add dilute sulfuric acid (aqueous solution) for slurry treatment. The solid-to-liquid ratio is 10g / L. Preheat to 70°C and place in airtight closed electrolysis In the tank, the titanium sheet is used as the anode, the carbon rod is used as the cathode, and the electrode current density is 500A / m 2 Carry out electrolysis (electrochemical treatment), apply mechanical stirring, the speed is 400rpm, and react for 6h to obtain a reaction slurry; filter the reaction slurry to obtain lithium-containing purification liquid and tailings, and obtain solid deposits on the surface of the cathode. The emission spectrometer (ICP) is used to analyze the content of various elements in the tailings, purified liquid and sediment, a...

Embodiment 2

[0067] The present embodiment provides a kind of method that lithium carbonate is prepared with lithium-containing electrode waste, and its concrete method is:

[0068] (1) Lithium cobaltate waste was roasted at 400°C for 2 hours, then added into dilute nitric acid for slurry treatment, the solid-to-liquid ratio was 15g / L, preheated to 85°C, placed in a closed electrolytic cell at atmospheric pressure, For the anode and cathode, the electrode current density is 800A / m2 Perform electrolysis, apply mechanical stirring, the rotating speed is 500rpm, and react for 4 hours to obtain a reaction slurry; the reaction slurry is filtered to obtain lithium-containing purification liquid and tailings, and solid deposits are obtained on the surface of the cathode, and ICP is used to treat the tailings, Analyze the content of each element in the purified liquid and sediment, and use XRD to analyze the phase structure of the sediment;

Embodiment 3

[0072] The present embodiment provides a kind of method that lithium carbonate is prepared with lithium-containing electrode waste, and its concrete method is:

[0073] (1) LiNi 0.5 co 0.2 mn 0.3 o 2 (NCM523) The waste material is pre-soaked in NaOH solution to remove the aluminum foil, washed and dried, and then added to dilute sulfuric acid for slurry treatment. The solid-to-liquid ratio is 30g / L. With carbon rods as anode and cathode, the current density is 800A / m 2 Perform electrolysis, apply mechanical stirring, the rotation speed is 700rpm, and react for 8 hours to obtain a reaction slurry; filter the reaction slurry to obtain lithium-containing purification liquid and tailings, and obtain solid substances on the surface of the cathode and anode, and use ICP to enrich Analyze the content of each element in the slag, filtrate, cathode deposits, and anode deposits, and use XRD to analyze the phase structure of the cathode deposits and anode deposits;

[0074] (2) addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com