Coiling device for coiling for knitting machine

A loop forming device, knitting machine technology, applied in knitting, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

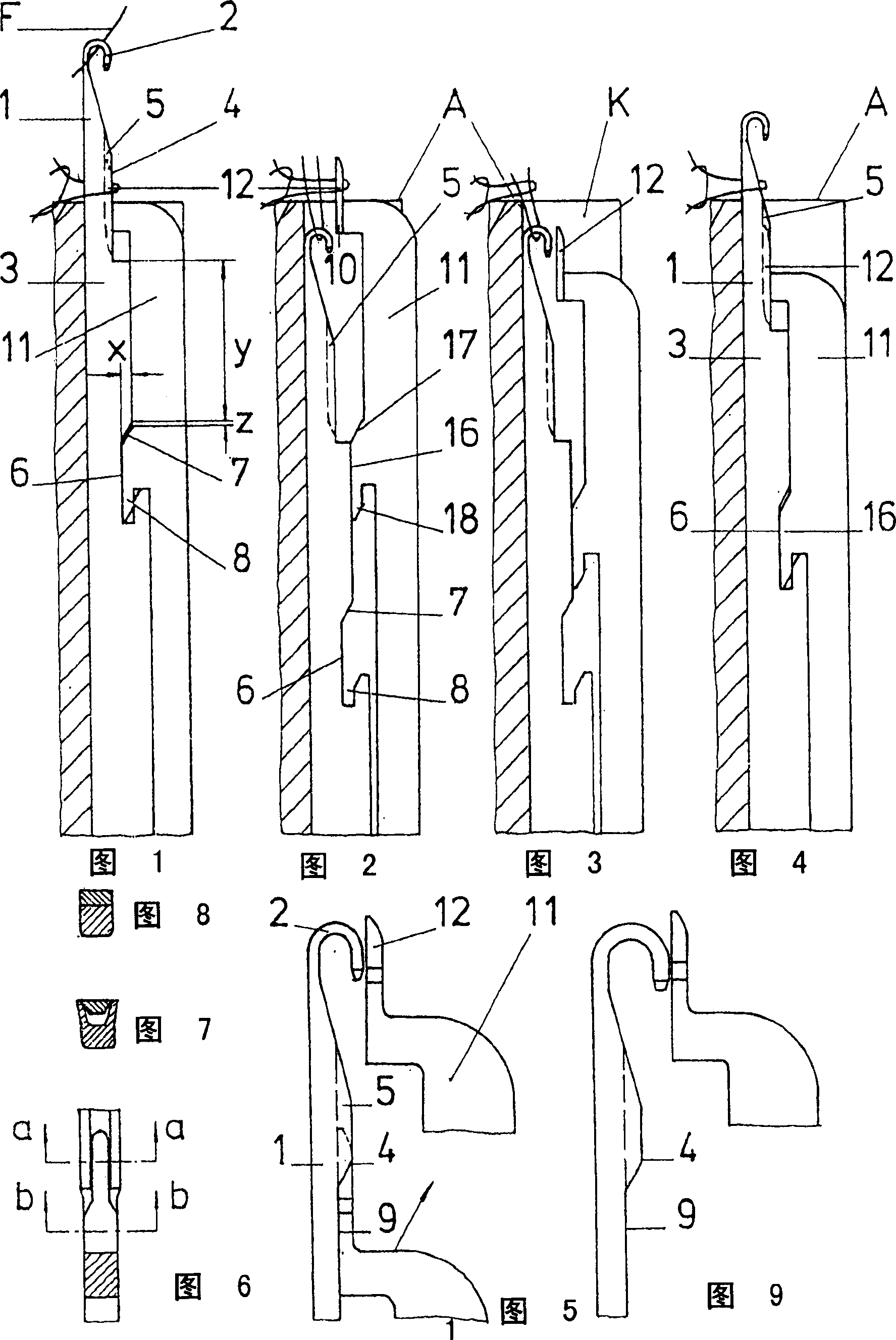

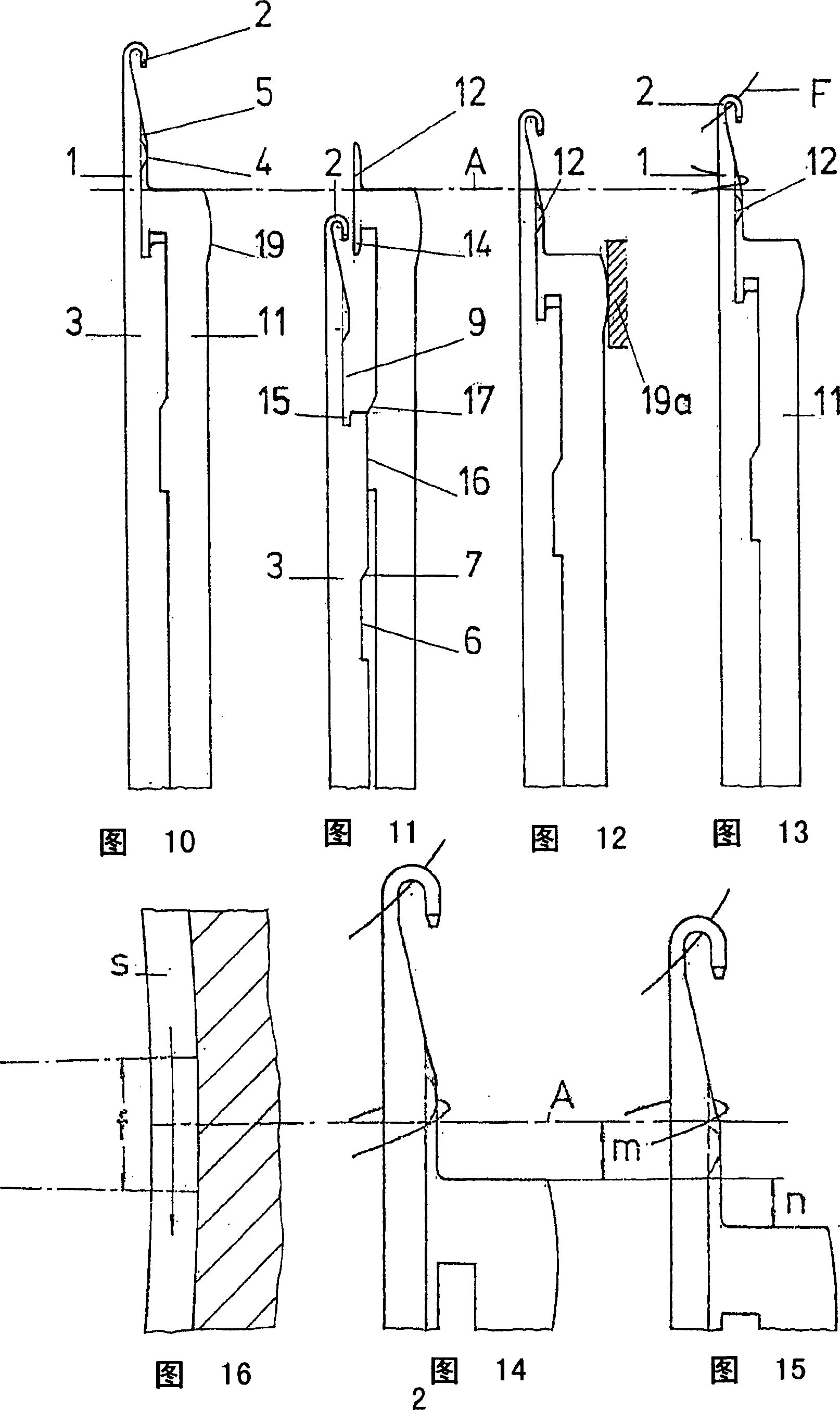

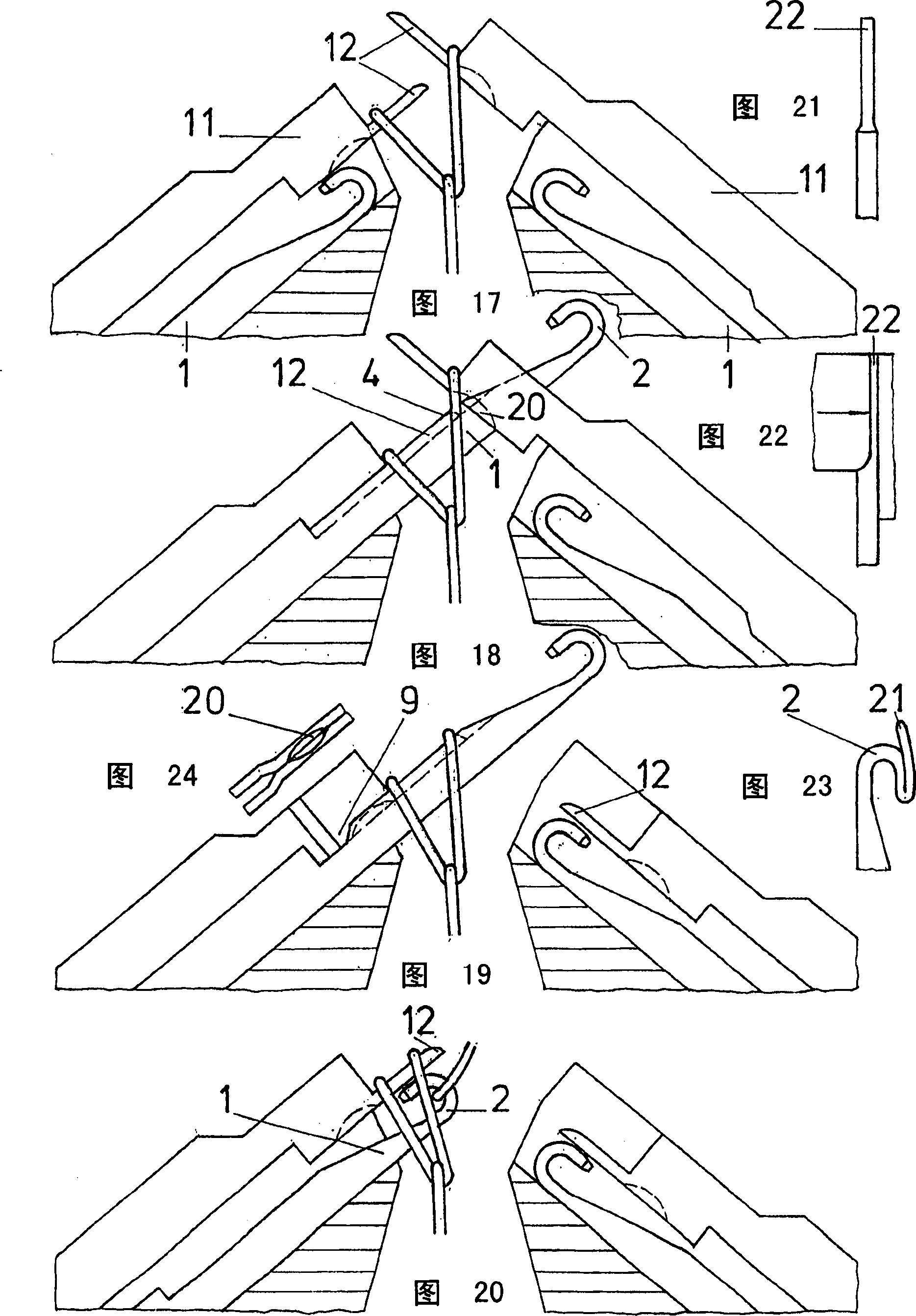

[0053] figure 1 Shown is needle 1 with needle shaft 3 and needle hook 2, which has received a thread F. An upwardly directed transfer hook 12 is arranged with its shaft 11 in operative connection with the needle hook 2 . The shaft 3 of the needle 1 has a notch 6 which is in contact with the finger-shaped projection 16 of the transfer hook 12 ( figure 2 )correspond. The recess 6 on the shaft of the needle 1 ends at the top with a riser 7 and at the bottom with a partially inclined notch 8 . At the same inclined finger-shaped portion 18 ( figure 2 ) together, this sliding surface facilitates engagement on both sides. The raised surface 7 on the needle shaft 3 and the beveled point 17 on the transfer hook shaft 11 are also arranged such that they are operatively connected when the needle 1 and the shaft of the transfer hook 12 are in a defined position.

[0054] There is a gap 8 below the rising surface 7 on the needle bar 3 . When the needle 1 and the transfer hook 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com