Method for recovering organic effluent brine

A waste brine and organic technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large consumption of steam in the stripper, untreated, high regeneration cost, etc. , to achieve obvious economic value, no secondary pollution, and outstanding economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

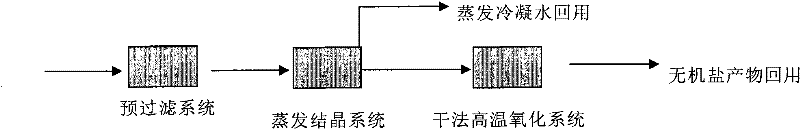

Image

Examples

Embodiment 1

[0040] The salt content of the process organic waste brine of a pesticide factory is 15%, its TOC is about 7000ppm, and the salt is mainly sodium chloride. The organic waste brine is treated by the method of the present invention.

[0041] First, the organic waste brine is introduced into the pre-filtration system to reduce the TOC of organic matter in the waste brine to 1000ppm. The filtration accuracy of the ultrafiltration device is about 0.03 microns in pore size, and the external pressure hollow ultrafiltration membrane (Krimmembrane Filtration Technology (Shanghai) Co., Ltd. KRIM-0850FR) is used. At the same time, the nanofiltration membrane is installed and the DK membrane of GE Company is used.

[0042] Then enter the evaporative crystallization system, so that after the obtained crystalline sodium chloride is formulated into saturated brine, its TOC is between 100 and 300 ppm. The evaporation and crystallization system adopts a three-effect evaporation device. Low-pr...

Embodiment 2

[0046] The hydrazine hydrate waste brine of a chemical plant is treated, the sodium chloride concentration of the waste water is about 12%, and the organic matter TOC content is between 200 and 300 ppm.

[0047] After the waste brine is filtered through an ultrafiltration membrane and evaporatively crystallized, the TOC of the crystalline sodium chloride is still 52 to 86 ppm after it is converted into saturated brine. The condensed water obtained by evaporation is reused as pure water.

[0048] Mix crystallized sodium chloride and oxidant, the oxidant uses chlorine-containing light brine, which contains sodium hypochlorite and sodium chlorate, the total concentration of chlorine-containing oxidant is about 1wt%, and its consumption is calculated by the weight converted into sodium hypochlorite, and the weight ratio of TOC It is 4.5:1.

[0049] After dry high-temperature oxidation at 300°C, the obtained sodium chloride product is converted into saturated brine, and its TOC dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com