A lithium iron phosphate with high compact density and a preparation method thereof

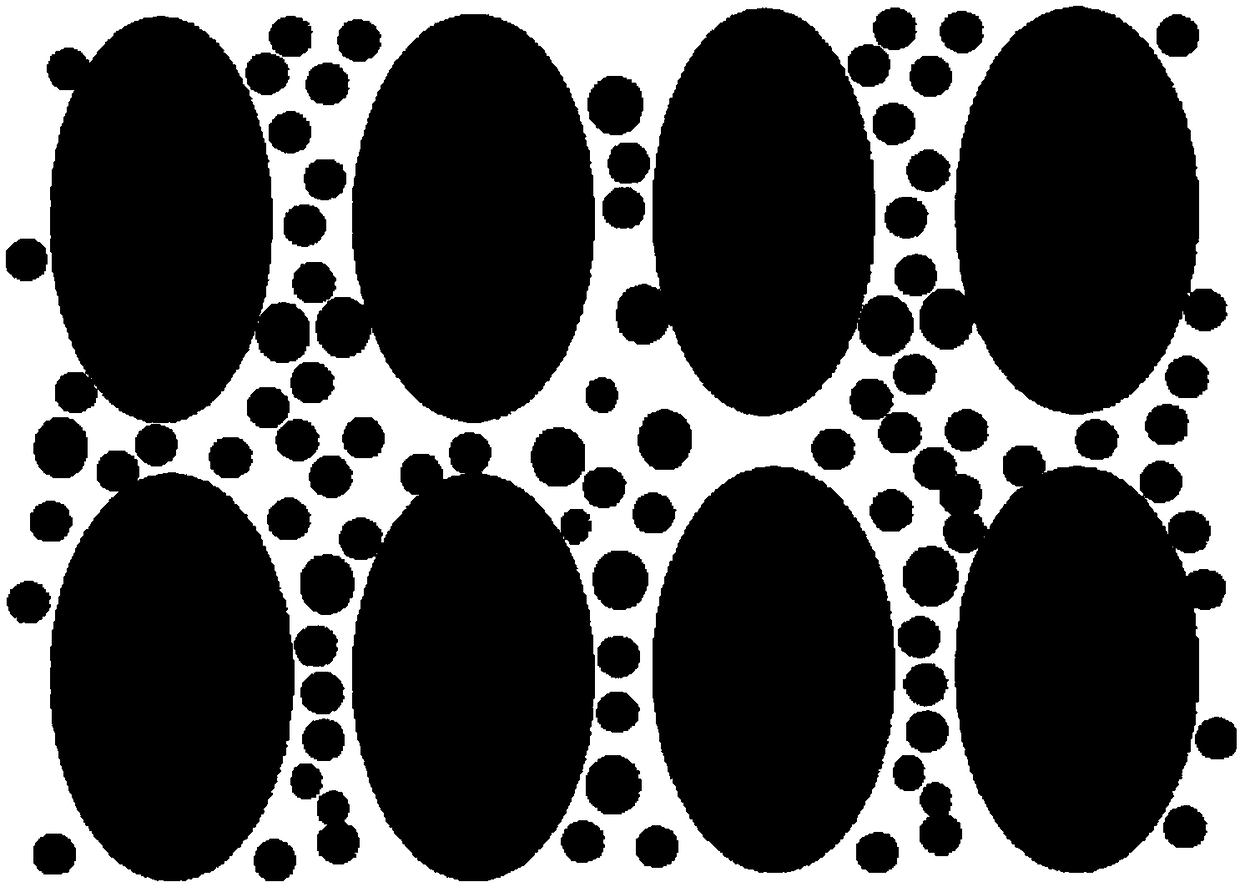

A technology of lithium iron phosphate and positive electrode material, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem that the compaction density and material properties of the pole pieces need to be further improved, the large particles and small particles are effectively filled, and the large and small particles are difficult to achieve. problems such as uniform mixing, to achieve the effect of directional and controllable growth, promotion of stability, and reduction of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

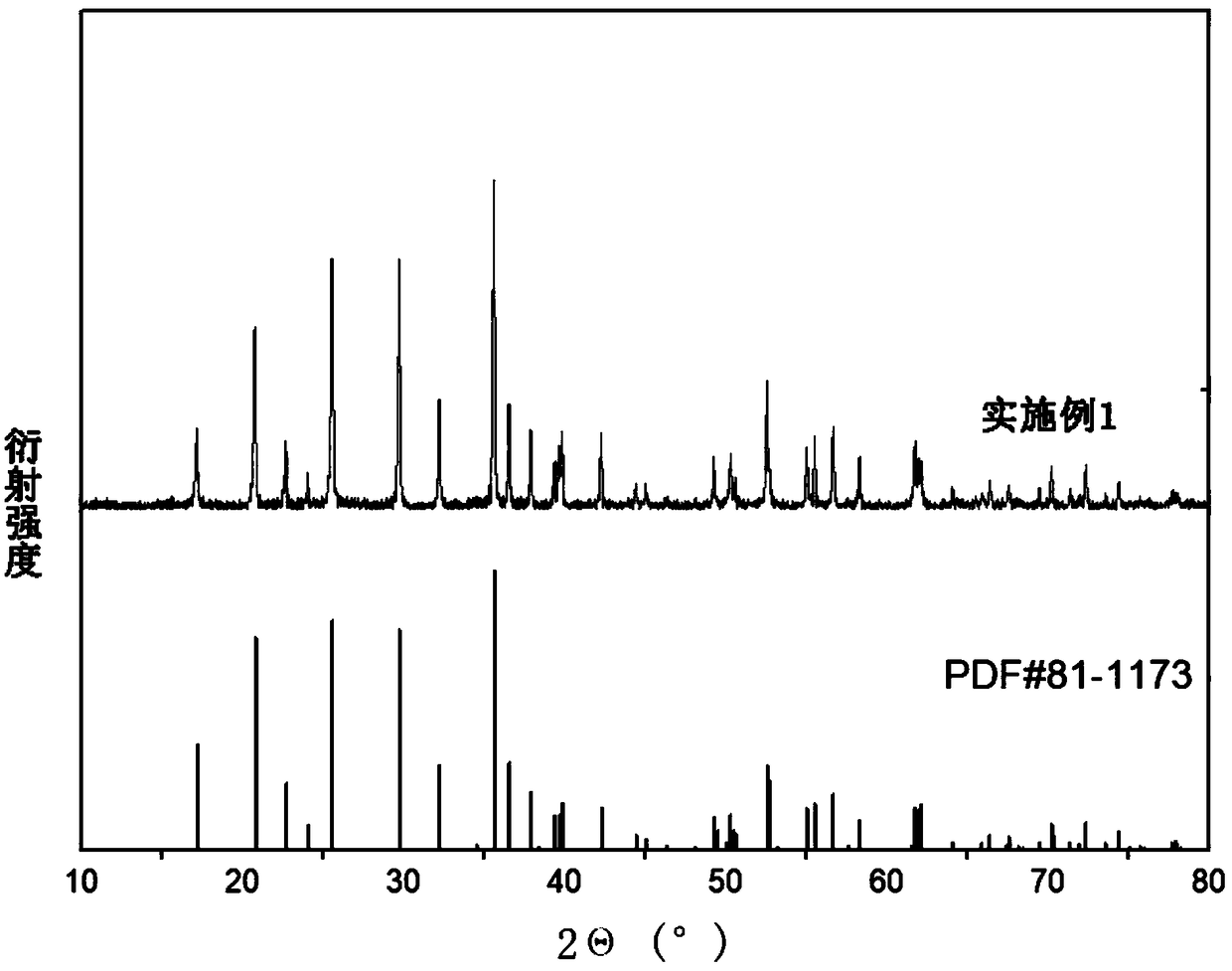

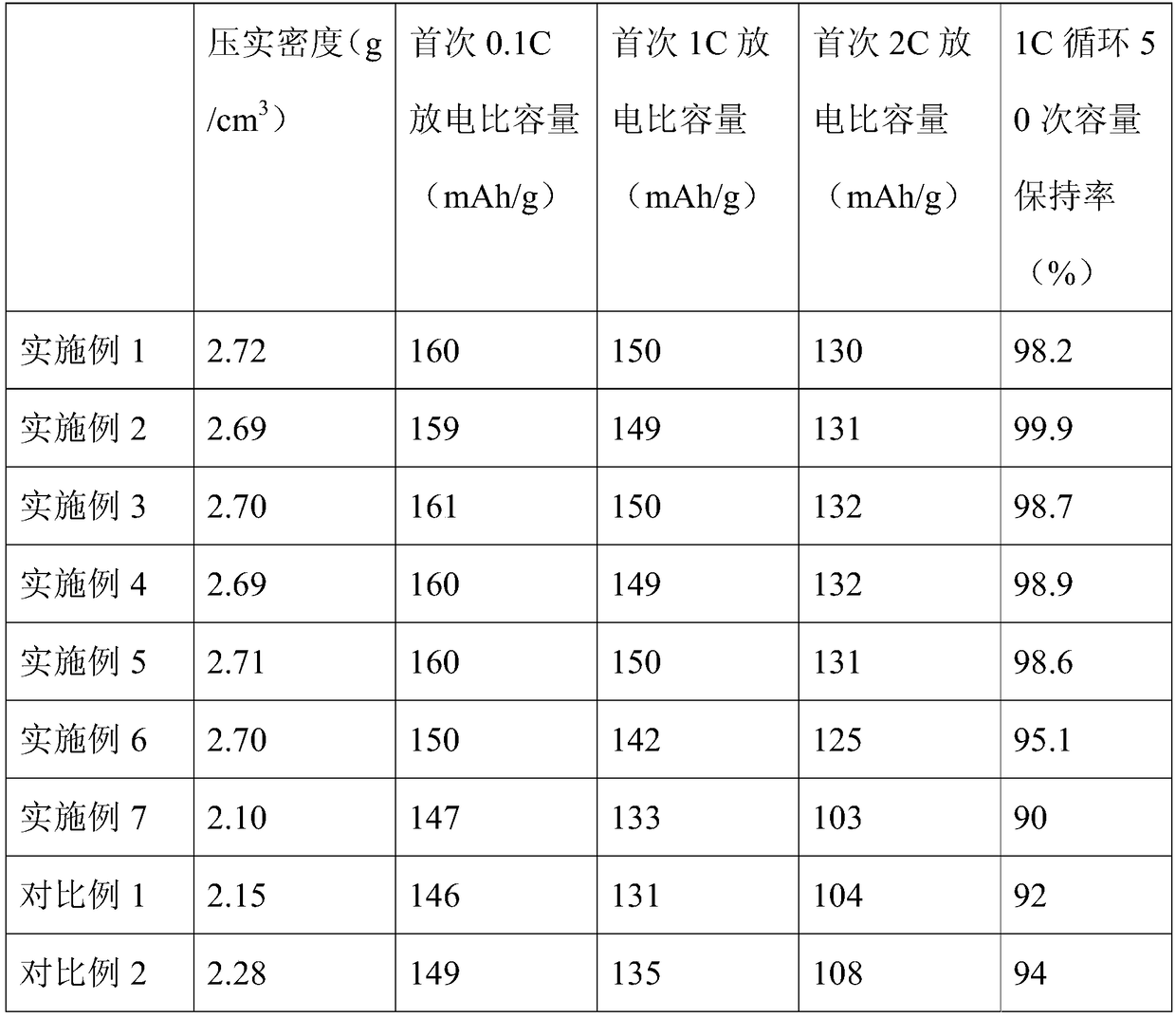

Embodiment 1

[0079] This embodiment prepares high compacted density lithium iron phosphate according to the following method:

[0080] (1) Provide the lithium iron phosphate precursor prepared by the solid phase method; place the lithium iron phosphate precursor prepared in step 1 and the nano-alumina catalyst in a ball mill for ball milling and mixing, and after mixing, obtain a mixed material; nano-alumina catalyst The mass fraction of the lithium iron phosphate precursor is 0.01%, and the particle size of the nanocatalyst is 1-4nm;

[0081](2) The mixed material is sintered in a nitrogen atmosphere, and at the same time, ethanol is intermittently introduced, and the mass of ethanol is 10% of the mass of the lithium iron phosphate precursor. The sintering operation is as follows: firstly, the temperature is raised to 300°C at a rate of 15°C / min and kept for 4 hours, then the temperature is raised from 300°C to 500°C at a rate of 30°C / min and kept for 16 hours, and then at a rate of 15°C / ...

Embodiment 2

[0087] This embodiment prepares high compacted density lithium iron phosphate according to the following method:

[0088] (1) Prepare the lithium iron phosphate precursor by liquid phase method; deposit titanium dioxide onto the surface of the lithium iron phosphate precursor prepared in step 1 by vapor phase deposition to obtain a mixed material; the nanometer titanium dioxide catalyst accounts for the mass of the lithium iron phosphate precursor The fraction is 1%; the particle size of the nano catalyst is 3-8nm;

[0089] (2) The mixed material is sintered in a nitrogen atmosphere, and at the same time, ethanol is intermittently introduced, and the mass of ethanol is 10% of the mass of the lithium iron phosphate precursor. The sintering operation is as follows: firstly, the temperature is raised to 500°C at a rate of 5°C / min and kept for 1 hour, then the temperature is raised from 500°C to 700°C at a rate of 10°C / min and kept for 3 hours, and then the temperature is raised a...

Embodiment 3

[0093] This embodiment prepares high compacted density lithium iron phosphate according to the following method:

[0094] (1) Provide a lithium iron phosphate precursor; dissolve the lithium iron phosphate precursor and magnesium oxide in a solvent to obtain a mixed material; the mass fraction of the nano-magnesium oxide catalyst in the lithium iron phosphate precursor is 2%; the particle size of the nano-catalyst The diameter is 6-10nm;

[0095] (2) The mixed material is sintered in a nitrogen atmosphere, and at the same time, ethanol is intermittently introduced, and the mass of ethanol is 10% of the mass of the lithium iron phosphate precursor. The sintering operation is as follows: firstly, the temperature is raised to 400°C at a rate of 10°C / min and kept for 2 hours, then the temperature is raised from 400°C to 600°C at a rate of 20°C / min and kept for 10 hours, and then at a rate of 12°C / min Raise the temperature from 600°C to 800°C and keep it warm for 2 hours; after si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com