Method for recovering lithium from lithium-containing electrode waste material

A lithium electrode, lithium recovery technology, applied in the direction of lithium oxide;/hydroxide, lithium carbonate;/acid carbonate, etc., can solve the problems of low lithium concentration and low lithium recovery rate, and achieve high High, short leaching time, easy industrial application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of method that reclaims lithium from lithium-containing electrode waste material, and its specific method is:

[0050] Put the lithium-ion battery positive electrode waste (lithium cobalt oxide battery positive electrode waste) in the tube furnace, and the gas flow rate is 1.0L min -1 H 2 , reduced and roasted at 800°C for 1 hour, then cooled with the furnace, and the gas was changed to 0.2L min during cooling -1 Ar. Take an appropriate amount of the reduced material, press 200g·L -1 Add deionized water to the solid-to-liquid ratio, place in a 50°C water bath for leaching for 60 minutes, and filter to obtain a lithium-rich aqueous solution and filter residue.

[0051] The lithium-containing product is prepared by distilling a lithium-rich aqueous solution with an evaporation crystallizer to obtain lithium hydroxide monohydrate.

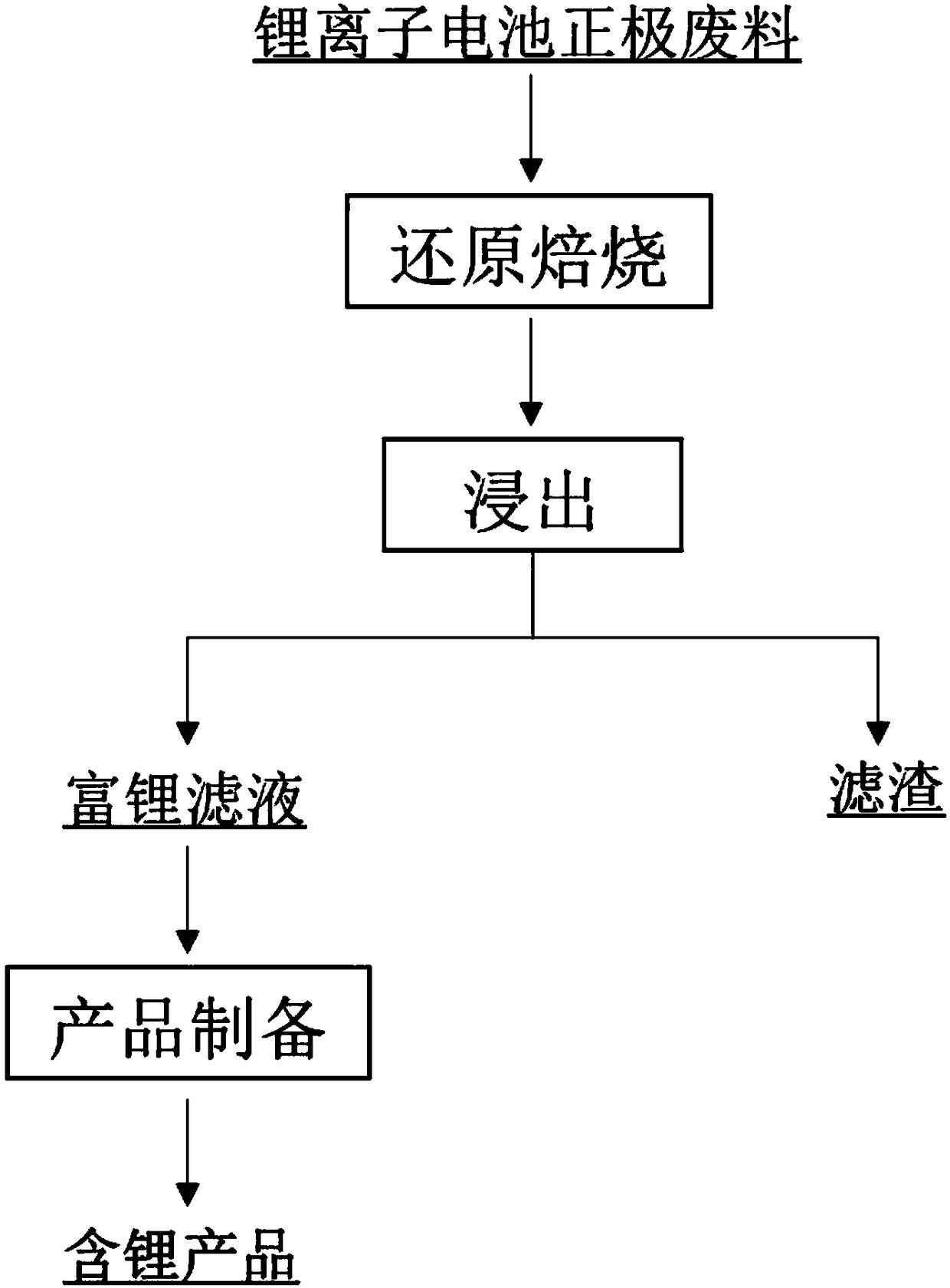

[0052] The process flow of the method for recovering lithium from lithium-containing electrode wast...

Embodiment 2

[0058] The present embodiment provides a kind of method that reclaims lithium from lithium-containing electrode waste material, and its specific method is:

[0059] Put the nickel-cobalt-lithium-manganese-oxide positive electrode waste into the tube furnace, and the gas flow rate is 0.5L min -1 H 2 , baked at 700°C for 4 hours, then cooled with the furnace, and the gas was changed to 0.2L min during cooling -1 Ar. Take an appropriate amount of the reduced material, press 100g·L -1 Add deionized water to the solid-liquid ratio, place in a 60°C water bath for leaching for 20 minutes, and filter to obtain a lithium-rich aqueous solution and filter residue.

[0060] Add 0.1L min to the lithium-rich aqueous solution at room temperature -1 Carbon dioxide, precipitated lithium carbonate.

[0061] In this example, the concentration of lithium in the lithium-rich aqueous solution was 8.3 g L as detected by ICP-OES -1 . According to XRD analysis, the main phases of filter residue...

Embodiment 3

[0066] The present embodiment provides a kind of method that reclaims lithium from lithium-containing electrode waste material, and its specific method is:

[0067] Put the positive electrode waste of nickel-cobalt lithium manganese oxide battery in a tube furnace, and the gas flow rate is 1.5L min -1 H 2 , baked at 700°C for 1 hour, then cooled with the furnace, and the gas was changed to 0.1L min during cooling -1 Ar. Take an appropriate amount of reduced material, press 300g·L -1 Add deionized water to the solid-to-liquid ratio, place in a 60°C water bath for leaching for 100 minutes, and filter to obtain a lithium-rich aqueous solution and filter residue.

[0068] Add 0.5L min to the lithium-rich aqueous solution at room temperature -1 Carbon dioxide, precipitated lithium carbonate.

[0069] In this example, the concentration of lithium in the lithium-rich aqueous solution is 20.8 g L as detected by ICP-OES -1 . According to XRD analysis, the main phases of filter r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com