Method for recycling manganese from positive electrode material of waste zinc-manganese dry battery and application

A zinc-manganese dry battery and positive electrode material technology, which is applied in the field of oxidation leaching manganese, can solve the problems of pollution, waste of resources and the environment, and achieve the effect of no pollution to the environment, good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

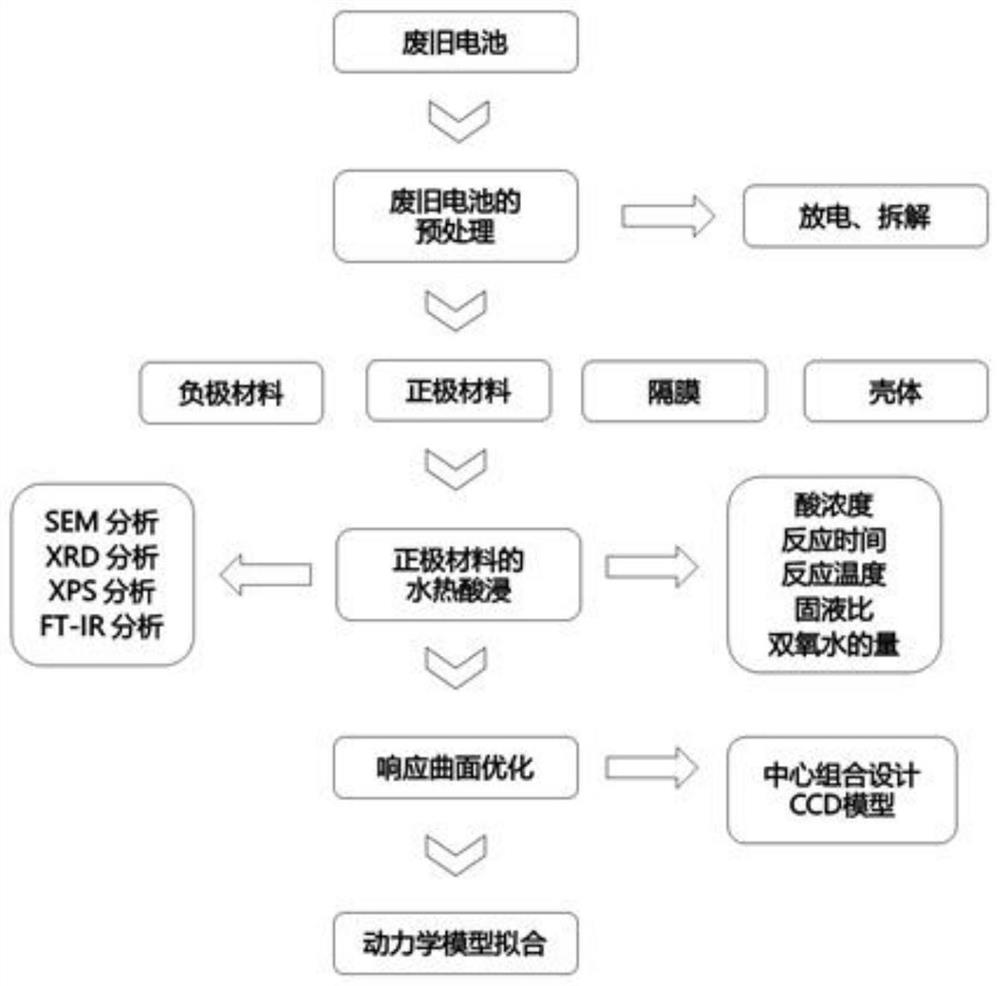

Method used

Image

Examples

Embodiment 1

[0037] Weigh a certain mass of battery cathode material powder and add it to 100mL phosphoric acid solution with a concentration of 2mol / L, and add 2vol.% hydrogen peroxide, and mix it into the lining of the reaction kettle. Seal and close the bolts of the reactor to ensure that there is no leakage, and continuously inject nitrogen gas for 5 minutes to remove the residual air in the reactor and prevent the possible interference of oxygen to the experiment. Start the heating device, the reactor will be heated to the set temperature, and keep it for a certain period of time (150°C, 100min). After finishing the reaction, the reactor will cool down naturally. After cooling to room temperature, the reaction kettle was opened, and the reacted mixed solution was suction-filtered to obtain manganese-containing leaching solution, and the measured manganese recovery rate was 96.4%.

Embodiment 2

[0039] Weigh a certain mass of battery cathode material powder and add it to 100mL phosphoric acid solution with a concentration of 2.5mol / L, and add 2.5vol.% hydrogen peroxide, mix and put it into the lining of the reactor. Seal and close the bolts of the reactor to ensure that there is no leakage, and continuously inject nitrogen gas for 5 minutes to remove the residual air in the reactor and prevent the possible interference of oxygen to the experiment. Start the heating device, the reactor will be heated to the set temperature, and keep it for a certain period of time (175°C, 110min). After finishing the reaction, the reactor will cool down naturally. After cooling to room temperature, the reaction kettle was opened, and the reacted mixed solution was suction-filtered to obtain manganese-containing leaching solution, and the measured manganese recovery rate was 97.6%.

Embodiment 3

[0041]Weigh a certain mass of battery cathode material powder and add it to 100mL phosphoric acid solution with a concentration of 3mol / L, and add 3vol.% hydrogen peroxide, and mix it into the lining of the reactor. Seal and close the bolts of the reactor to ensure that there is no leakage, and continuously inject nitrogen gas for 5 minutes to remove the residual air in the reactor and prevent the possible interference of oxygen to the experiment. Start the heating device, the reactor will be heated to the set temperature, and keep it for a certain period of time (200°C, 120min). After finishing the reaction, the reactor will cool down naturally. After cooling to room temperature, the reaction kettle was opened, and the reacted mixed solution was suction-filtered to obtain manganese-containing leaching solution, and the measured manganese recovery rate was 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com