Super-mirror polishing method of metal plate

A metal plate, super-mirror technology, used in surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of short solution life, complex process, high cost, and achieve a wide range of applications and flexible operation. , the effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Select a pure molybdenum plate with a size of 1.0×50×70mm, first use a surface grinder to grind the surface of the molybdenum plate, and obtain a flat shape with a flatness error of about 5 μm; then select three types of 1000#, 1500# and 2000# in turn Grind the surface of the material with a type of water-grinding sandpaper. The grinding time of each type of sandpaper is 3 to 5 minutes to obtain a relatively bright surface without impurities; finally, use W3.0 abrasive paste to apply it on the sponge disc of the polishing machine to finely polish the surface of the molybdenum plate During the treatment process, a small amount of clean water is kept to wet the treated surface; after a period of polishing, the sponge coated with abrasive paste is removed to a certain thickness, and W3.0 abrasive paste is applied to the sponge to continue the polishing process. Machine grinding time is 3-5 minutes in total until the pure molybdenum plate shows an abnormally bright effect. ...

Embodiment 2

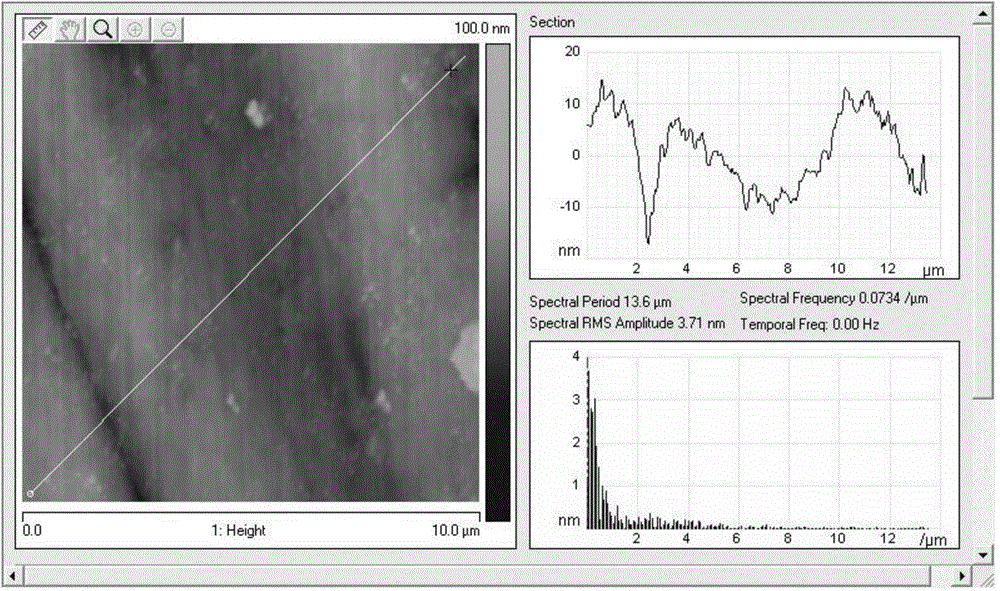

[0023] Select a cold-rolled red copper plate with a thickness of 2.0mm, cut out a plate with a length and width of 50×70mm, and directly choose 2000# water-grinding sandpaper to polish the surface of the material. Straight surface; Finally, apply W2.5 abrasive paste on the sponge plate of the polishing machine to finely polish the copper plate, and keep a small amount of clean water to wet the surface during the treatment process; after a period of polishing, the sponge Wear off a certain thickness of the layer, and then use W1.5 abrasive paste to be applied to the sponge plate of the polishing machine to continue polishing. The polishing time of the polishing machine is 3 to 5 minutes, until the copper plate shows an abnormally bright effect. For the relatively soft copper in the metal material, the surface after treatment is detected by atomic force microscope, and the roughness Ra is 3.39nm, which realizes the super mirror effect.

Embodiment 3

[0025] Select a pure iron plate with a thickness of 2.0mm, cut out a plate with a length and width of 50×70mm, and first select a two-roller cold rolling machine with a bright roll for 5% cold rolling treatment, so that the surface flatness error is about 10μm, the roughness reaches Ra0.8, and the surface after rolling is treated with acid and alkali degreasing, degreasing and deoxidation; choose 2000# water-grinding sandpaper to polish the surface of the material, and the sanding time is 3 to 5 minutes to obtain impurities-free and relatively bright The surface of the surface; finally use W2.5 abrasive paste to be applied on the sponge plate of the polishing machine, and the pure iron plate is finely polished, and a small amount of water is kept to wet the surface during the treatment process; after a period of polishing, the sponge Wear off a certain thickness of the layer, and then use W1.5 abrasive paste to be applied on the sponge plate of the polishing machine to continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com