Miniature connector and preparation method thereof

A technology of micro connector and manufacturing method, which is applied in the direction of connection, contact box/base manufacturing, contact parts, etc., can solve the problems of high cost of SOI substrate, easy to be restricted and removed, and increased cost of micro connector manufacturing. Achieve the effect of improving production yield, good production yield, and best production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

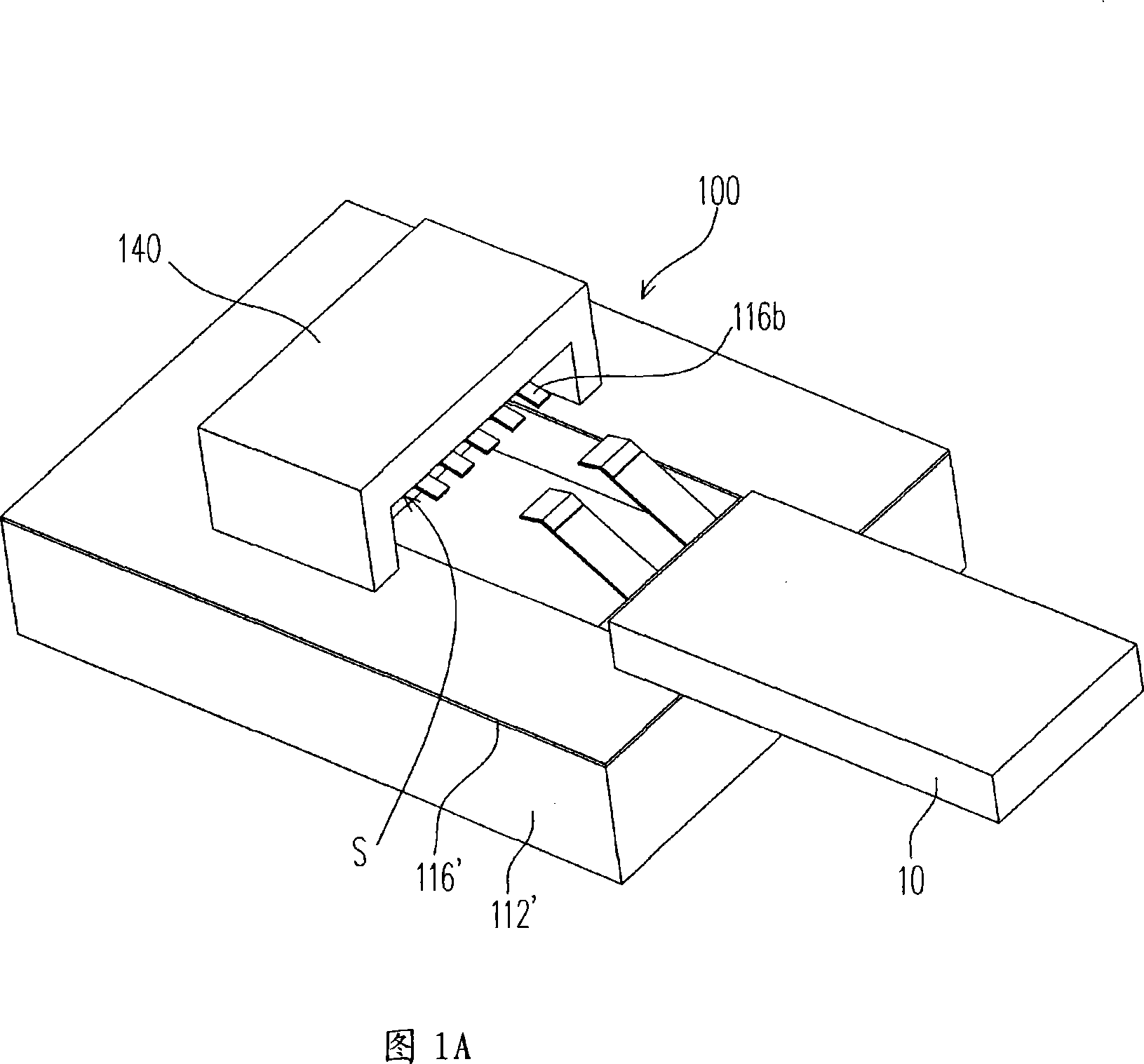

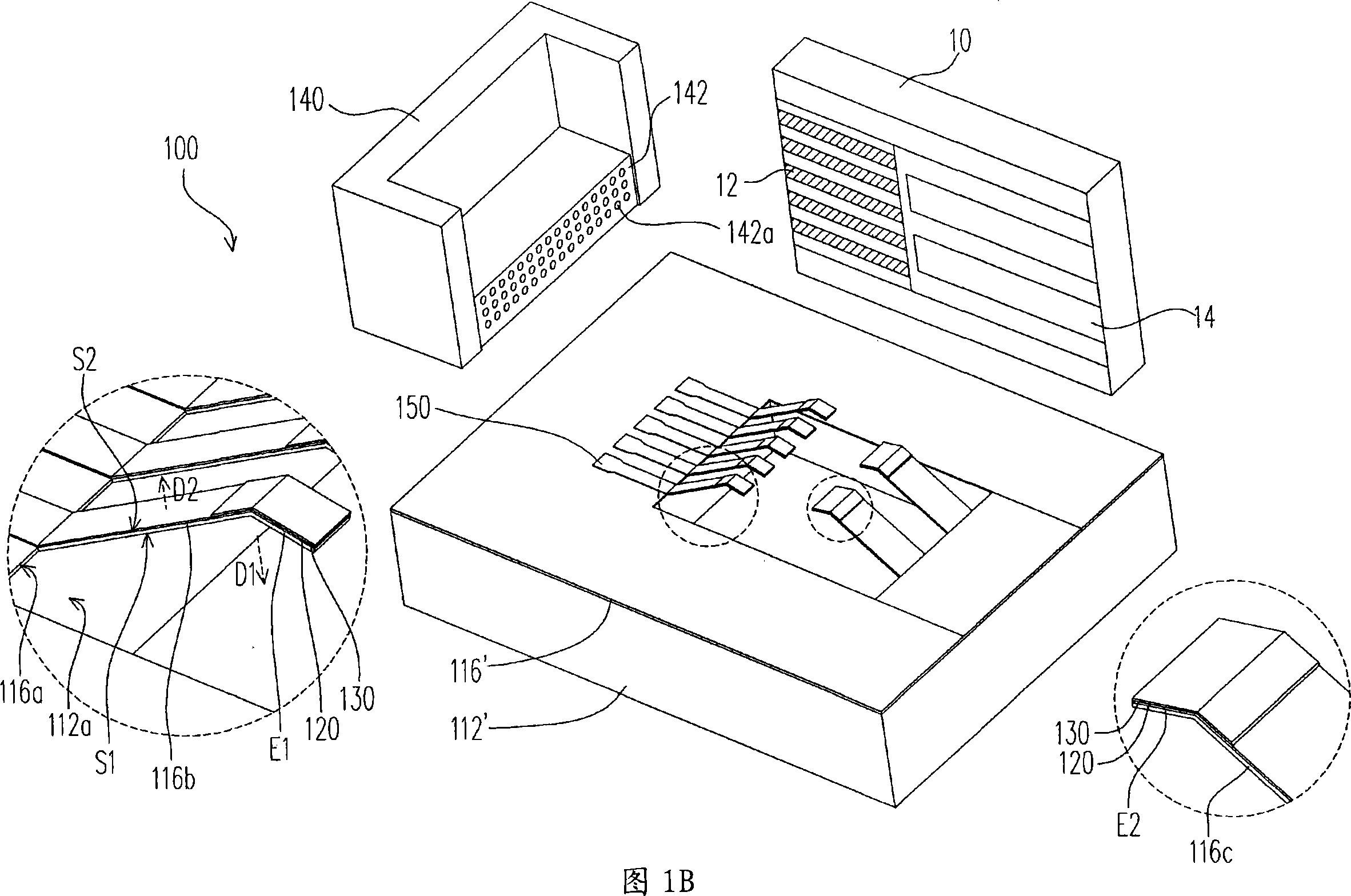

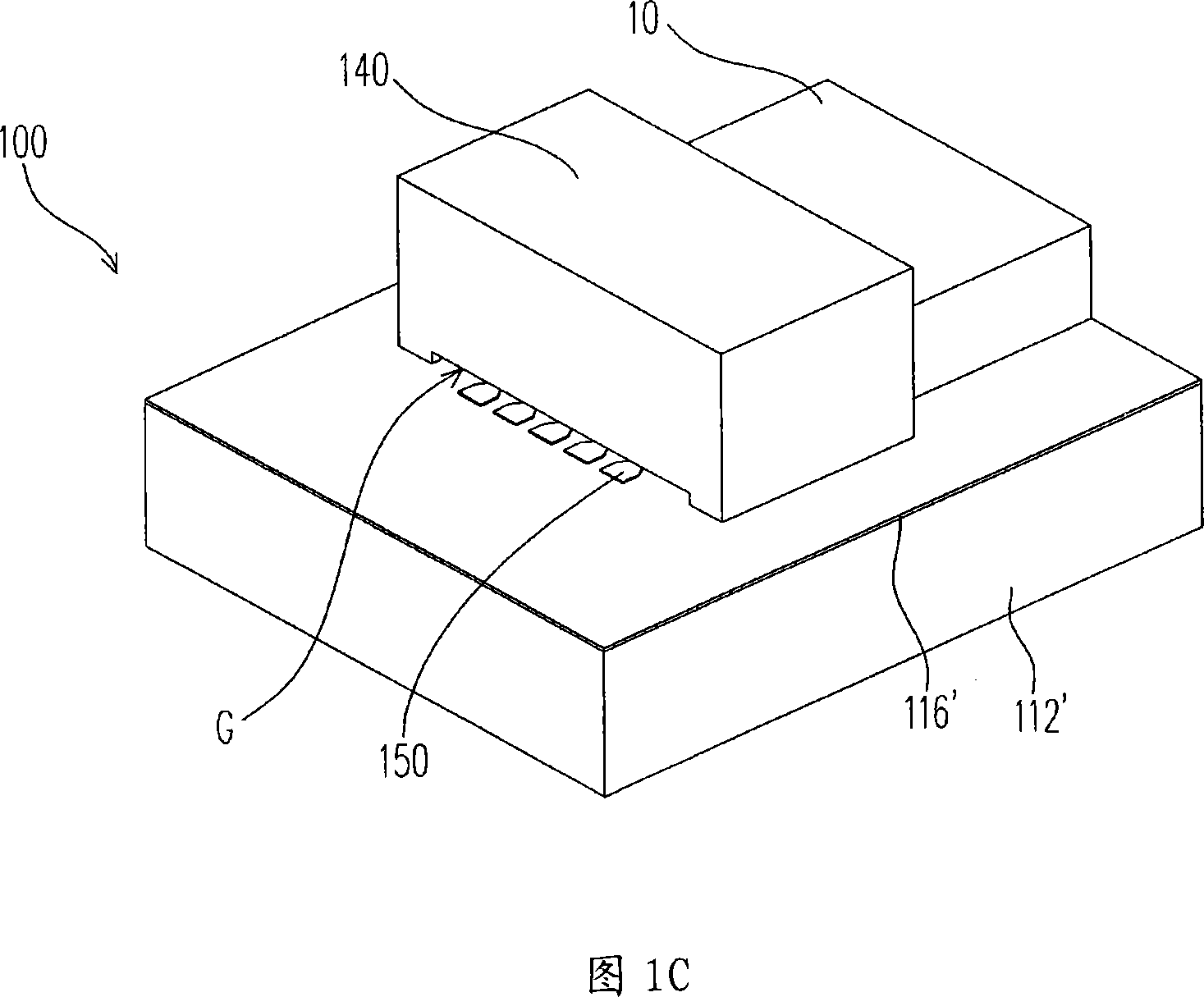

[0046] Figure 1A A schematic diagram illustrating a micro connector and an insert according to an embodiment of the present invention, Figure 1B draw Figure 1A exploded view of the miniature connector with insert. Please also refer to Figure 1A and Figure 1B The micro-connector 100 of this embodiment is suitable for being arranged in thinner and lighter electronic devices, and the micro-connector 100 is suitable for inserting the insert 10 so that the electronic device has better performance. The micro-connector 100 of the present embodiment mainly includes a patterned silicon material layer 112', and the material is, for example, silicon dioxide (SiO 2 ), a patterned insulating layer (insulator) 116', at least one first stress layer 120, at least one second stress layer 130, and a cover 140. Wherein, the first stress layer 120 is, for example, a diamond like carbon (DLC) film or other suitable materials, the material of the second stress layer 130 is, for example, gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com