Method for extraction treating of copper-cobalt alloy by using metal melt

A metal melt and alloy technology, applied in the field of smelting, can solve the problems of serious equipment loss, high energy consumption in the pretreatment process, and high hardness of copper-cobalt alloys, and achieve the effects of low cost, good leaching effect, and easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

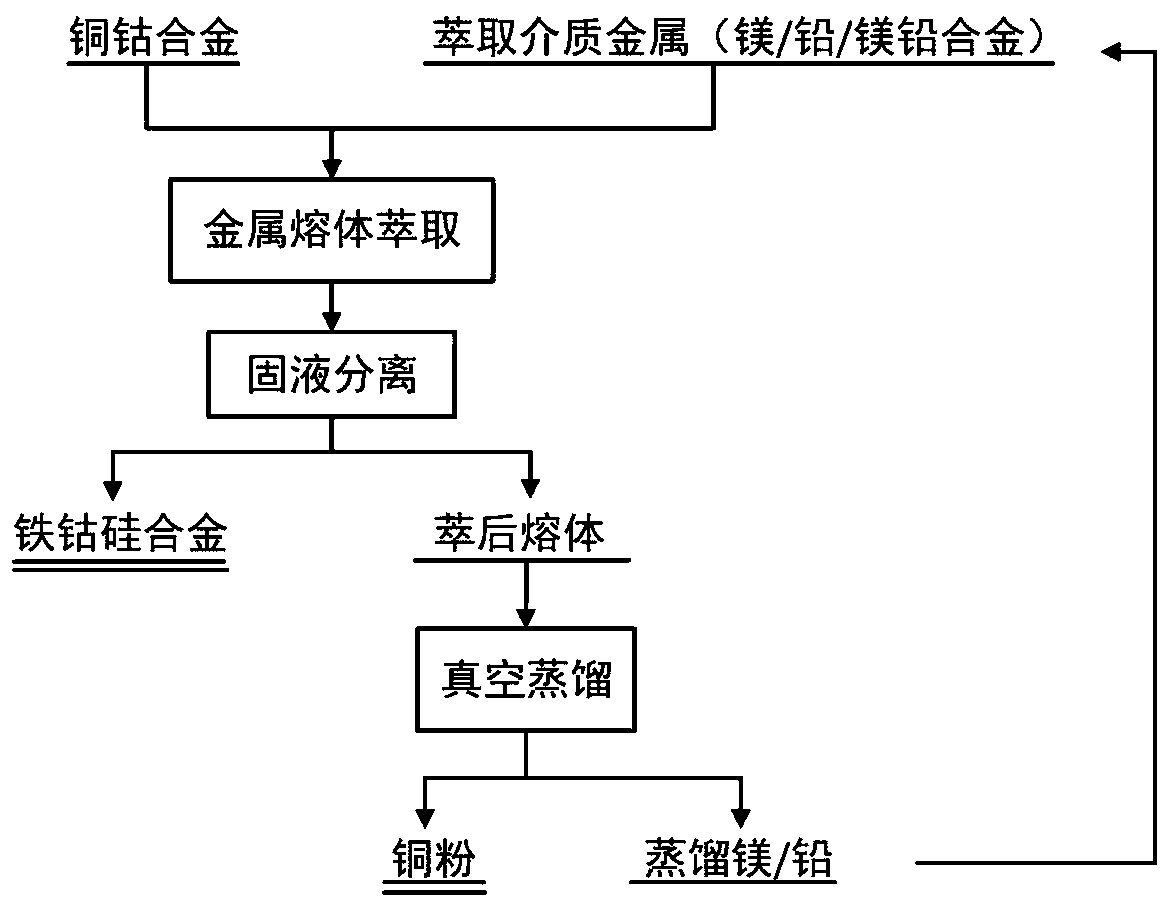

[0036] A kind of method utilizing metal melt extraction of the present invention to process copper-cobalt alloy comprises the following steps:

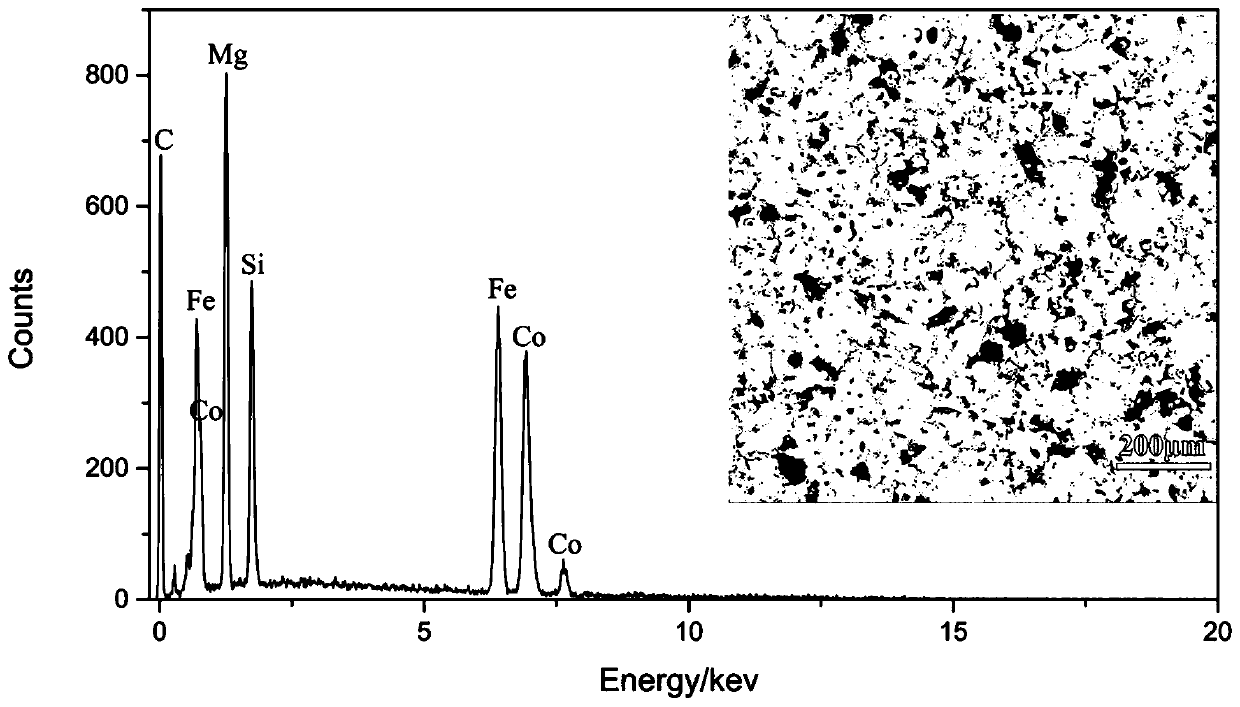

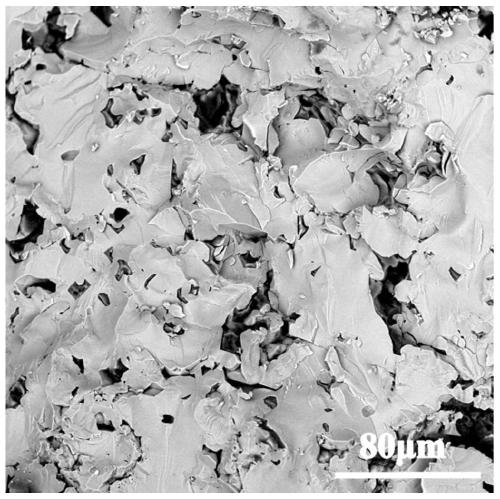

[0037] (1) Mix copper-cobalt alloy (Cu 21.8%, Co 33.8%, Fe 33.3%, Si11.2%) with a particle size of 0.1 to 2 mm and magnesium particles (the mass ratio of alloy to magnesium is 1:5), and add it to the crucible In this method, the magnesium is melted by heating to 850°C under an inert protective atmosphere. After 1 hour, the tube furnace is tilted to make the melt flow through the titanium mesh and separate from the residual alloy. The morphology of the residual alloy is shown in figure 2 , it can be seen that the surface of the residual alloy is porous;

[0038] (2) The extracted melt separated in step (1) was distilled at 100 Pa and 900° C. for 2 hours to separate magnesium and copper.

[0039] Adopt inductively coupled plasma optical emission spectrometer to detect the composition of residual alloy and distill and separate the comp...

Embodiment 2

[0042] A kind of method utilizing metal melt extraction of the present invention to process copper-cobalt alloy comprises the following steps:

[0043] (1) Mix copper-cobalt alloy (Cu 21.8%, Co 33.8%, Fe 33.3%, Si11.2%) with a particle size of 0.1 to 2 mm and magnesium and lead particles with a mass ratio of 1:3 (copper-cobalt alloy and magnesium The mass ratio of the total mass of lead is 1:5), put it into the crucible, heat to 900°C under an inert protective atmosphere to melt the magnesium and lead, and tilt the tube furnace after 1 hour to make the melt flow through the titanium mesh to separate from the residual alloy ;

[0044] (2) Distill the extracted melt at 50 Pa and 1100°C for 2 hours to separate magnesium, lead and copper.

[0045]Use an inductively coupled plasma emission spectrometer to detect the composition of the residual alloy and the composition of the copper powder separated by distillation, and extract the mass percentage of each component in the residual...

Embodiment 3

[0047] A kind of method utilizing metal melt extraction of the present invention to process copper-cobalt alloy comprises the following steps:

[0048] (1) Mix copper-cobalt alloy (Cu 21.8%, Co 33.8%, Fe 33.3%, Si 11.2%) with a particle size of 2 to 4 mm with magnesium particles (the mass ratio of copper-cobalt alloy to magnesium is 1:10), add In the crucible, heat to 800°C under an inert protective atmosphere to melt the magnesium. After 1 hour, tilt the tube furnace to make the melt flow through the titanium mesh to separate from the residual alloy;

[0049] (2) Distill the extracted melt for 1 hour under the conditions of 100 Pa and 900° C. to separate magnesium and copper.

[0050] Use an inductively coupled plasma emission spectrometer to detect the composition of the residual alloy and the composition of the copper powder separated by distillation, and extract the mass percentage of each component in the residual alloy Cu 0.1%, Co 41.5%, Fe 43.2%, Si14.2% , the mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com