Oil-water separation device and oil-water separation method

An oil-water separation device and technology for oil-water separation, which is applied in the field of oil-water separation devices and oil-water separation, can solve the problems of low removal rate, easy pollution, and low removal rate of oil droplets, and achieve the effect of high separation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

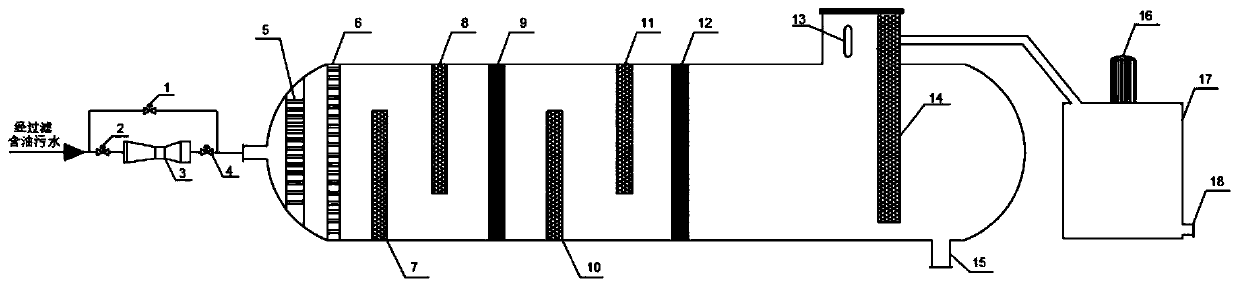

[0064] This embodiment provides an oil-water separation device, referring to figure 1 As shown, it includes a flow rate control unit, an oil-water separation unit and a dirty oil extraction and storage unit. The oil-water separation unit is set between the flow rate control unit and the waste oil extraction and storage unit. The filtered oily wastewater is first passed through the flow rate control unit to control the fluid flow rate, and then passed into the oil-water separation unit to separate oil and water. The separated oil Pass into the dirty oil and draw it out of the storage unit for storage.

[0065] The flow rate control unit includes a Venturi tube 3 , a second valve 2 and a third valve 4 are respectively arranged before and after the Venturi tube 3 , and a first valve 1 is also arranged on a pipeline connected in parallel with the Venturi tube 3 . When performing oil-water separation, the second valve 2 and the third valve 4 can be opened, and the oily waste water...

Embodiment 2

[0081] This embodiment provides an oil-water separation device, and the only difference from Embodiment 1 is that the first oil droplet polymerization separator 7, the second oil droplet polymerization separator 8, the third oil droplet polymerization separator 10 and the fourth oil droplet polymerization separator The materials of the drop polymerization separator 11 are all PVP, and in order to improve the hydrophilicity of the PVP, polyacrylic acid is sprayed on the surface of the PVP board.

[0082] The opening ratio of the oil droplet polymerization separator is 40%, and the inside is filled with polyurethane material. The polyurethane composite material is loaded with the first material and the second material. In this embodiment, the first material is nano-zinc oxide, and the second material is For ammonium polyphosphate, the diameter of the oil droplet polymerization separator is smaller than the diameter of the tank.

[0083] The rest of the structure and materials ar...

Embodiment 3

[0085] This embodiment provides an oil-water separation device, and the only difference from Embodiment 1 is that the first oil droplet polymerization separator 7, the second oil droplet polymerization separator 8, the third oil droplet polymerization separator 10 and the fourth oil droplet polymerization separator The materials of the drop polymerization separator 11 are all PVA, and no material is sprayed on the surface of the PVA plate in this embodiment.

[0086] The opening ratio of the oil droplet polymerization separator is 40%, and the inside is filled with a polyurethane material, and the polyurethane composite material is loaded with a first material and a second material. In this embodiment, the first material is nano-zinc oxide and graphene. The second material is polyhexammonium bromide, and the diameter of the oil drop polymerization separator is smaller than that of the tank body.

[0087] The rest of the structure and materials are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com