Method for selectively separating tantalum and niobium step by step based on floating extraction

A selective, tantalum-niobium technology, applied in the field of selective fractional separation of tantalum and niobium based on flotation extraction, can solve problems such as selective deep separation of difficult tantalum and niobium, and achieve selective fractional separation of tantalum and niobium, high-efficiency separation, high-efficiency enriched effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

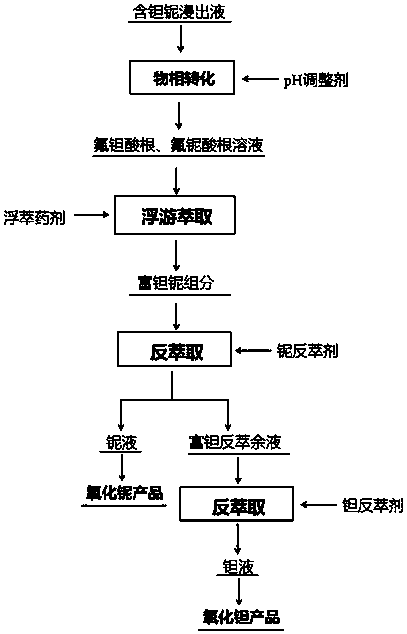

[0024] A method for the selective step-by-step separation of tantalum and niobium based on planktonic extraction, such as figure 1 As shown, the process is as follows:

[0025] (1) Add hydrofluoric acid with a concentration of 35wt% ~ 40wt% to 1 L solution with a concentration of tantalate radicals of 5 g / L and a concentration of niobate radicals of 5 g / L, so that the tantalum and niobium in the solution are converted into tantalum fluoride and fluorine Niobate, control the free hydrofluoric acid in the solution to 1 wt% ~ 2wt%. Add a floating extraction agent to the above solution, and its composition is: 50 parts by mass of dodecylamine, 30 parts by mass of methyl isobutyl ketone, 20 parts by mass of humic acid, the concentration is 10 g / L, and then add sodium hexametaphosphate to disperse The concentration is 200 mg / L, air is passed into the solution to form microbubbles with a diameter of 100 nm~10 μm, and the hydrophobic mineralized bubbles-fluorine tantalum / niobate-flot...

Embodiment 2

[0031] A method for the selective step-by-step separation of tantalum and niobium based on planktonic extraction, such as figure 1 As shown, the process is as follows:

[0032] (1) Add hydrofluoric acid with a concentration of 20wt% to 30wt% to 1L solution with a concentration of tantalate radicals of 2 g / L and a concentration of niobate radicals of 200 mg / L, so that the tantalum and niobium in the solution are converted into fluorotantalate and fluoroniobium Acid radicals, control the free hydrofluoric acid in the solution to 1 wt% ~ 2 wt%. Add a floating extraction agent to the above solution, which is composed of: 50 parts by mass of dodecylamine, 30 parts by mass of methyl isobutyl ketone, 20 parts by mass of humic acid with a concentration of 5 g / L, and then add sodium hexametaphosphate to disperse The concentration is 100 mg / L, the solution is filled with air to form microbubbles with a diameter of 100 nm~10 μm, and the hydrophobic mineralized bubbles-fluorine tantalum / ...

Embodiment 3

[0038] A method for the selective step-by-step separation of tantalum and niobium based on planktonic extraction, such as figure 1 As shown, the process is as follows:

[0039] (1) Add hydrofluoric acid with a concentration of 10wt% ~ 20wt% to 1 L solution with a concentration of tantalate radicals of 100 mg / L and a concentration of niobate radicals of 100 mg / L, so that the tantalum and niobium in the solution are converted into fluorotantalate radicals, fluorine Niobate, control the free hydrofluoric acid in the solution to 1 wt% ~ 2 wt%. Add a floating extraction agent to the above solution, and its composition is: 50 parts by mass of dodecylamine, 30 parts by mass of methyl isobutyl ketone, 20 parts by mass of humic acid, the concentration is 200 mg / L, and then add sodium hexametaphosphate to disperse The concentration is 50 mg / L, the solution is filled with air to form microbubbles with a diameter of 100 nm~10 μm, and the hydrophobic mineralized bubbles-fluorine tantalum / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com