A method for selective step-by-step separation of tantalum and niobium based on planktonic extraction

A selective, tantalum-niobium technology, applied in the field of selective step-by-step separation of tantalum-niobium based on planktonic extraction, can solve difficult problems such as selective deep separation of tantalum-niobium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

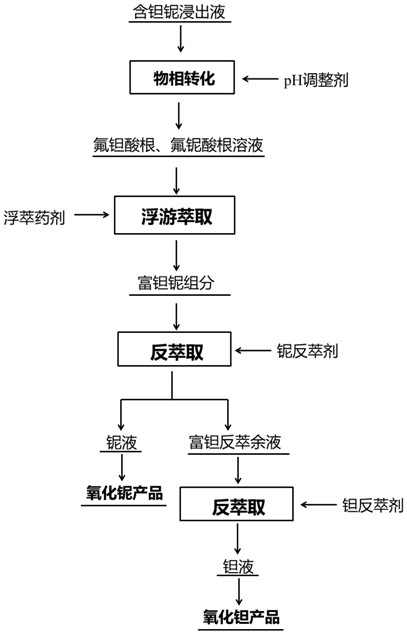

[0024] A method for the selective step-by-step separation of tantalum and niobium based on planktonic extraction, such as figure 1 As shown, the process is as follows:

[0025] (1) Add hydrofluoric acid with a concentration of 35wt%~40wt% to 1 L solution with a concentration of tantalate radicals of 5 g / L and a concentration of niobate radicals of 5 g / L, so that the tantalum and niobium in the solution are converted into tantalum fluoride and fluorine Niobate, control the free hydrofluoric acid in the solution to 1 wt% ~ 2 wt%. Add a floating extraction agent to the above solution, and its composition is: 50 parts by mass of dodecylamine, 30 parts by mass of methyl isobutyl ketone, 20 parts by mass of humic acid, the concentration is 10 g / L, and then add sodium hexametaphosphate to disperse The concentration is 200 mg / L, air is passed into the solution to form microbubbles with a diameter of 100 nm~10 μm, and the hydrophobic mineralized bubbles-fluorine tantalum / niobate-flota...

Embodiment 2

[0031] A method for the selective step-by-step separation of tantalum and niobium based on planktonic extraction, such as figure 1 As shown, the process is as follows:

[0032] (1) Add hydrofluoric acid with a concentration of 20wt% to 30wt% to 1L solution with a concentration of tantalate radicals of 2 g / L and a concentration of niobate radicals of 200 mg / L, so that the tantalum and niobium in the solution are converted into fluorotantalate and fluoroniobium Acid radicals, control the free hydrofluoric acid in the solution to 1 wt% ~ 2 wt%. Add a floating extraction agent to the above solution, which is composed of: 50 parts by mass of dodecylamine, 30 parts by mass of methyl isobutyl ketone, 20 parts by mass of humic acid with a concentration of 5 g / L, and then add sodium hexametaphosphate to disperse The concentration is 100 mg / L, the solution is filled with air to form microbubbles with a diameter of 100 nm~10 μm, and the hydrophobic mineralized bubbles-fluorine tantalum / ...

Embodiment 3

[0038] A method for the selective step-by-step separation of tantalum and niobium based on planktonic extraction, such as figure 1 As shown, the process is as follows:

[0039] (1) Add hydrofluoric acid with a concentration of 10wt% ~ 20wt% to 1 L solution with a concentration of tantalate radicals of 100 mg / L and a concentration of niobate radicals of 100 mg / L, so that the tantalum and niobium in the solution are converted into fluorotantalate radicals, fluorine Niobate, control the free hydrofluoric acid in the solution to 1 wt% ~ 2 wt%. Add a floating extraction agent to the above solution, and its composition is: 50 parts by mass of dodecylamine, 30 parts by mass of methyl isobutyl ketone, 20 parts by mass of humic acid, the concentration is 200 mg / L, and then add sodium hexametaphosphate to disperse The concentration is 50 mg / L, the solution is filled with air to form microbubbles with a diameter of 100 nm~10 μm, and the hydrophobic mineralized bubbles-fluorine tantalum / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com