Device and method for conducting diffusion dialysis and electrolysis electrodialysis integrated treatment on vanadium-alkali feed liquid in alkali method vanadium extraction process

A technology of electrolytic electrodialysis and diffusion dialysis, which is applied in the field of integrated treatment of diffusion dialysis and electrolytic electrodialysis, can solve the problems of separating vanadium alkali material liquid, blank, and none, and achieve the effect of fast separation speed, simple process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

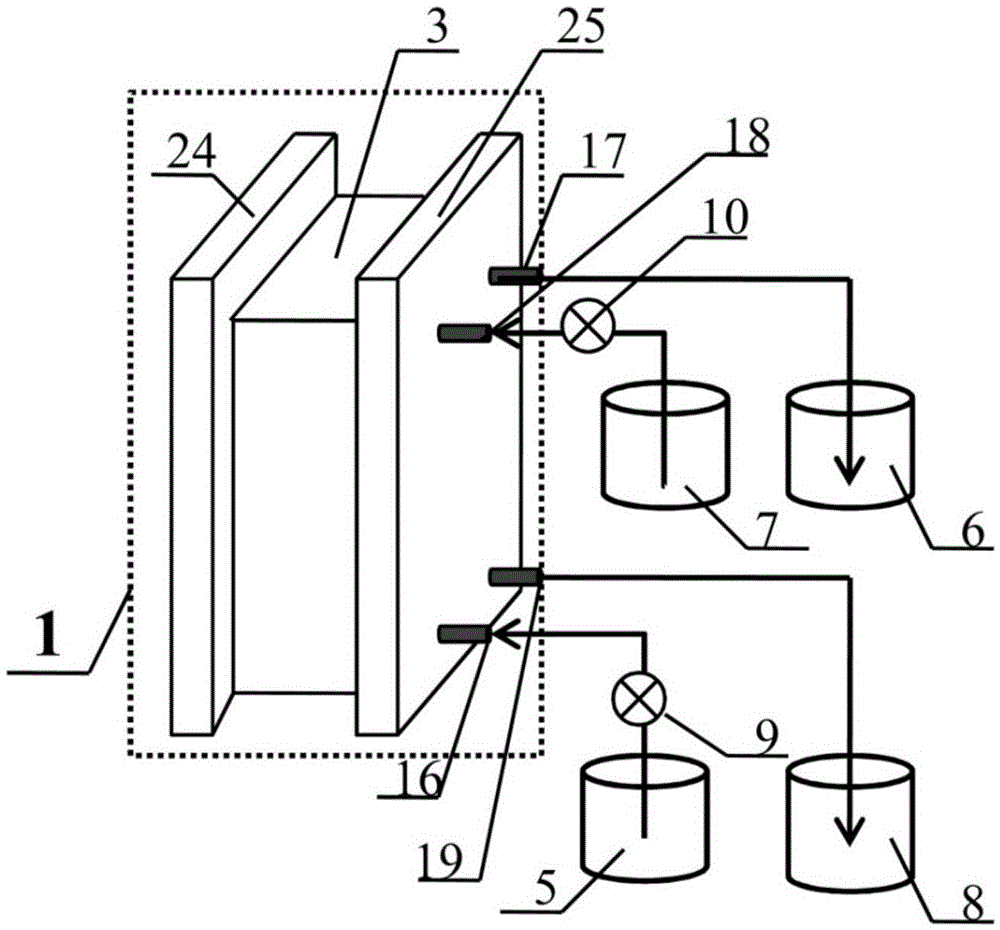

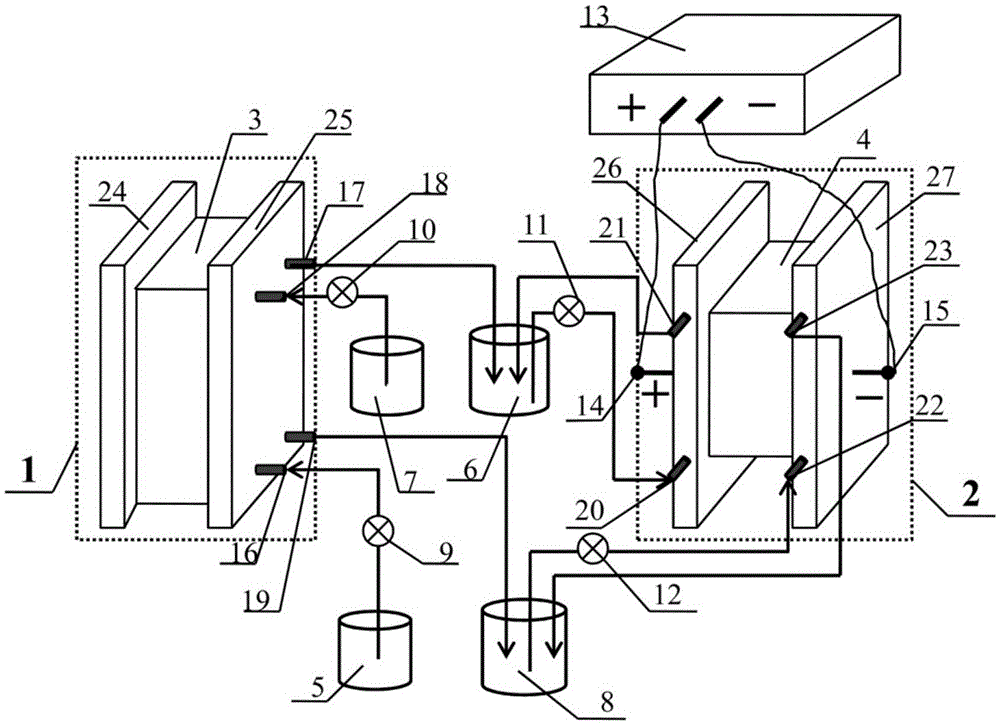

[0033] figure 1 It is a schematic diagram of the diffusion dialysis device used in this example. The diffusion dialysis device is assembled in the following way: PVA series cation exchange membranes (13 sheets) produced by Shandong Tianwei Membrane Technology Co., Ltd. and gaskets with grids are assembled alternately to form 7 repeating units (7 pieces) feed liquid chamber and 7 alkali recovery chambers) membrane stack-DD3, the effective area of each membrane is 69cm 2 , the total effective membrane area is 0.0897m 2 , The thickness of the gasket with grid is 0.8mm. The membrane stack-DD3 is clamped with the DD front splint 25 and the DD rear splint 24 by bolts to form a diffusion dialysis device 1 . The DD feed liquid chamber inlet 16 and the DD feed liquid chamber outlet 17 are respectively connected to the inside of the feed liquid storage tank 5 and the retentate tank 6 through silicone tubes, and the DD alkali recovery chamber inlet 18 and the DD alkali recovery cham...

Embodiment 2

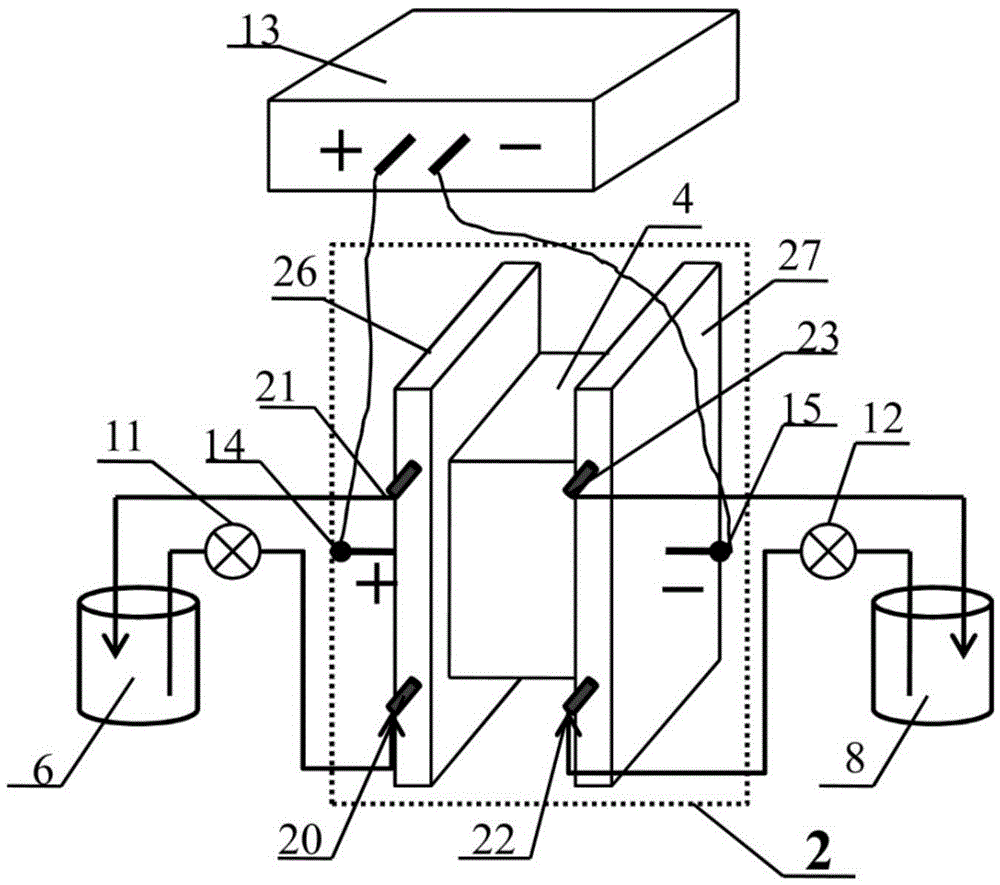

[0040] figure 2 It is a schematic diagram of the electrolytic electrodialysis device used in this example. The electrolytic electrodialysis device is assembled in the following way: a membrane stack-EED2 is formed by using a cation exchange membrane CMV (1 sheet) produced by Asahi Glass Co., Ltd., a gasket and a flow channel grid, and the membrane stack includes an anode chamber and One cathode chamber, the effective area of the membrane is 189cm 2 , The gasket thickness is 0.8mm. The membrane stack-EED4 is clamped by bolts with the EED positive electrode 14 and the EED negative electrode 15 respectively arranged at both ends of the membrane stack, and the EED front splint 26 and EED rear splint 27 arranged at both ends of the electrode to form an electrolytic electrodialysis device 2 . Its EED anode chamber inlet 20 and EED anode chamber outlet 21 are respectively connected to the inside of the anolyte tank 6 through silicone tubes, and the EED cathode chamber inlet 22 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com