Method for deeply purifying titanium dioxide copperas

A green vitriol and titanium dioxide technology, which is applied in the direction of ferric sulfate, can solve the problems of limited purification effect, increased raw material cost, and large amount of fluoride, and achieves low cost, low amount of precipitant, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

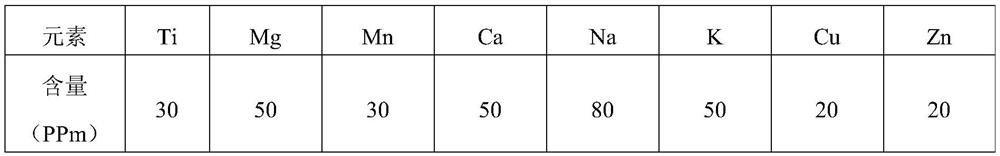

[0035] (1) The raw material of titanium dioxide by-product green vitriol was obtained from Panzhihua Dongfang Titanium Industry. According to chemical analysis, the content of ferrous sulfate in its main components was 83.2%, the content of titanyl sulfate was 7.6%, the content of magnesium sulfate was 5.1%, and the content of manganese sulfate 1.3%, and the remaining impurity content such as calcium sulfate, sodium potassium and the like is 2.8%. Take 2 kg of the above-mentioned green vitriol, dissolve it in 5000 mL of 0.005 mol / L dilute sulfuric acid, add 4 g of reduced iron powder under the state of heating and stirring slightly, until the solution boils slightly, keep the state of boiling for 1 hour, stop heating, wait After the solution was cooled, the solution was filtered under reduced pressure, and impurities such as hydrolyzed metatitanic acid impurities and unreacted iron powder were filtered off to obtain a light green clarified ferrous sulfate solution;

[0036] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com