Oil-water separating device and method

An oil-water separation device, oil-water separator technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of secondary pollution, easy blockage of packing, long residence time, etc., achieve uniform short circuit and reduce processing load , reduce the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

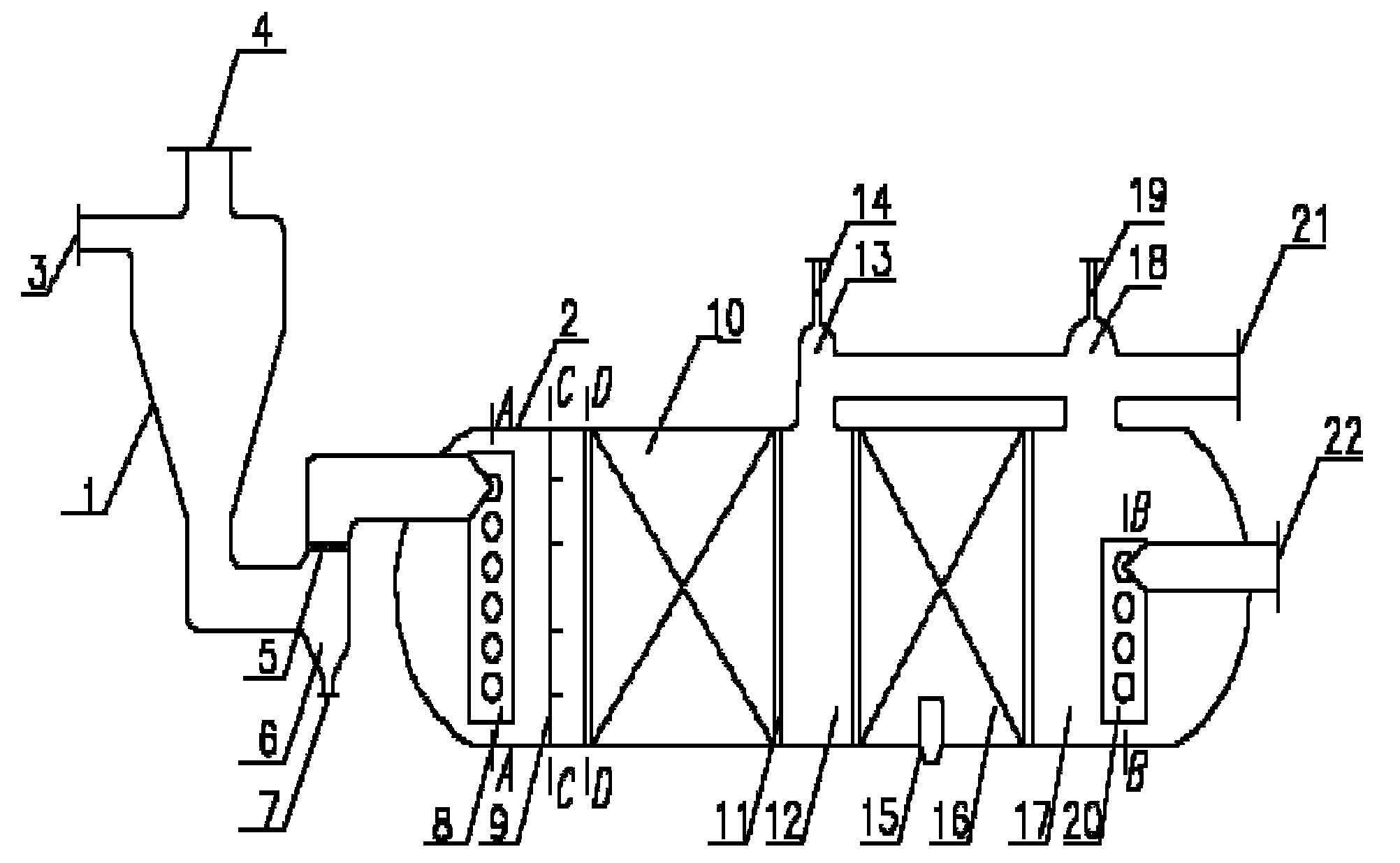

[0020] The present invention will be described in further detail below according to accompanying drawing:

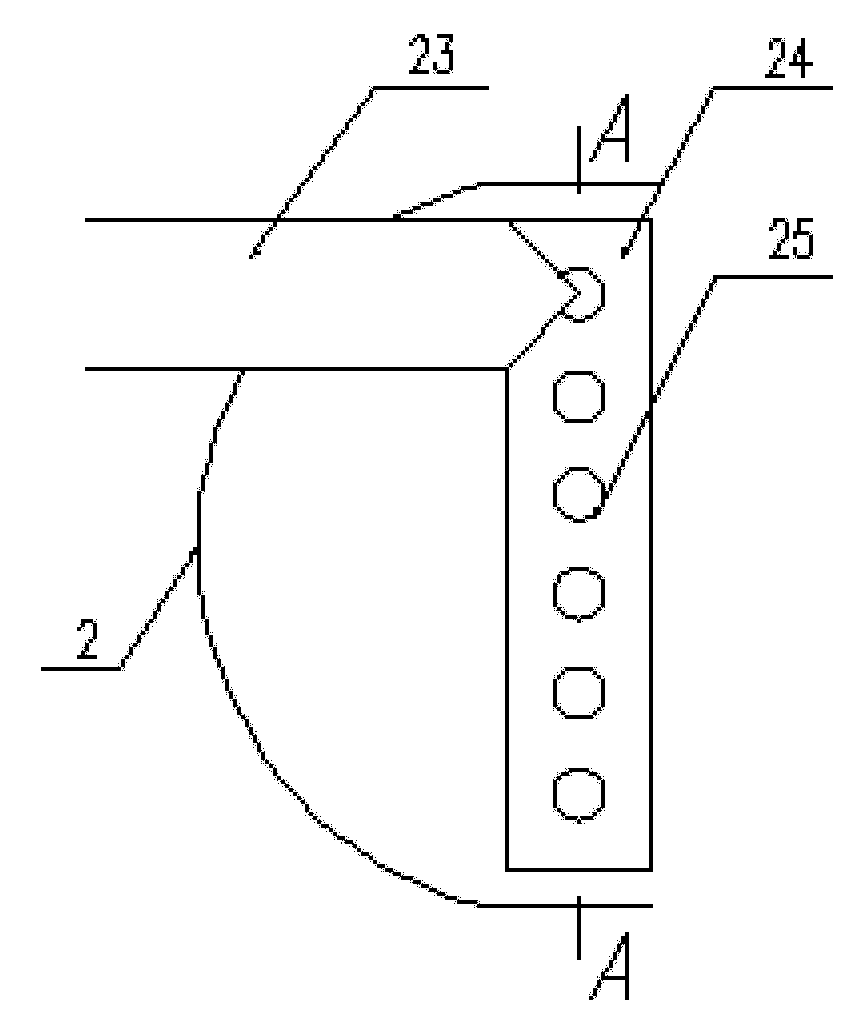

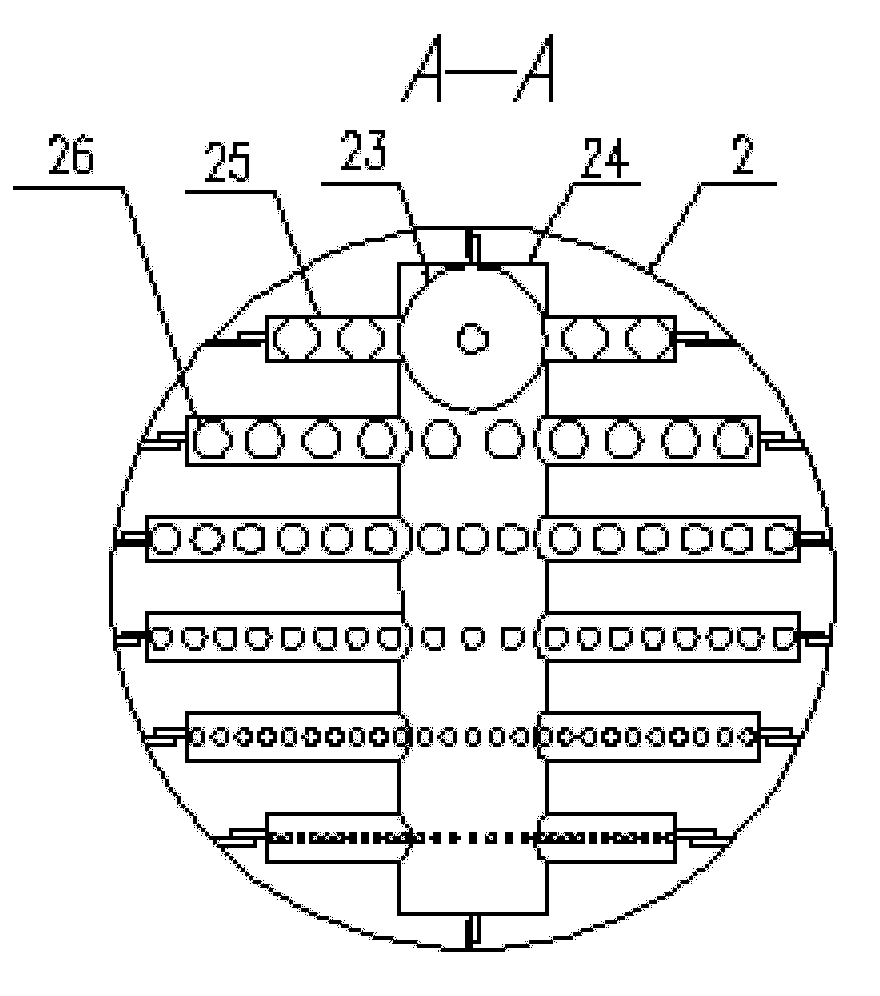

[0021] The oil-water separation device includes a cyclone 1 with a U-shaped underflow pipe and a horizontal coalescing oil-water separator 2 with the function of uniform liquid distribution, see attached figure 1 . Among them, the cyclone 1 is used as the pre-separation zone, the horizontal coalescing oil-water separator 2 is used as the main separation zone, and the liquid outlet of the U-shaped bottom flow pipe of the cyclone is connected with the inlet of the horizontal coalescing oil-water separator. The horizontal coalescing oil-water separator is provided with an inlet liquid distributor 8, a rectifying sieve plate 9, a stainless steel plate corrugated packing coalescing area 10, a polypropylene wire mesh corrugated packing coalescing area 16, and an outlet liquid collector 20 in sequence. The stainless steel plate corrugated packing coalescing area 10 and the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com