Method for directly preparing zinc oxide by wet treatment of zinc-containing fumes in iron and steel plants

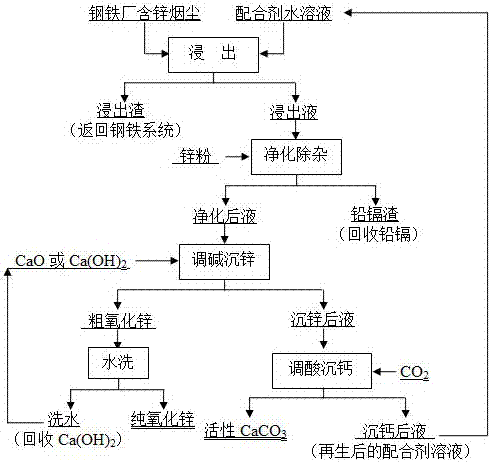

A technology of wet treatment and iron and steel plant, which is applied in the field of zinc oxide prepared by wet treatment of zinc-containing smoke and dust in iron and steel plants, which can solve the problems of harsh operating environment, difficult recycling of liquid after zinc precipitation, high acid consumption, etc., and achieves low environmental toxicity and side effects , Low equipment anti-corrosion requirements, mild leaching system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Smoke dust from a steel factory, its main components (wt%): Zn 10.37, Fe 23.32, CaO 7.63, MgO 1.07, Cd2.58 and Pb 1.09; Reagent: Food grade glycine, content ≥ 99%; Analytical pure sodium hydroxide, Content ≥99%; Analytical pure zinc powder, content ≥99%; Analytical pure calcium oxide (CaO), content ≥98%; Industrial carbon dioxide gas, content ≥99%.

[0040](1) Leaching: at 70°C, use glycine and sodium hydroxide to make the pH value 9, and the total concentration of glycine is 1.5mol L -1 300mL of aqueous solution, according to the liquid-solid ratio of 6:1, add 50g of smoke and dust for leaching, after 4 hours of reaction, solid-liquid separation, leaching solution 250mL; among them, the concentration of Zn is 19.90g L -1 , Pb concentration 2.05g L -1 , Cd concentration 4.90g·L -1 , Fe concentration 10.20mg·L -1 ; During the leaching process, the Zn leaching rate was 95.9%, the Pb leaching rate was 94.0%, the Cd leaching rate was 95.0%, and the Fe leaching rate was 0...

Embodiment 2

[0045] Smoke from a steel plant, its main components (wt%): Zn 27.52, Fe 24.78, CaO 8.06, MgO 1.32, Cd4.80 and Pb 3.14; Reagent: Food grade glycine, content ≥ 99%; Industrial grade sodium glycine, Content ≥ 98%; analytical pure zinc powder, content ≥ 99%; analytical pure calcium oxide (CaO), content ≥ 98%; industrial carbon dioxide gas, content ≥ 99%.

[0046] (1) Leaching: at 85°C, use glycine and sodium glycine to make pH 8, and the total concentration of glycine is 3.5mol L -1 400mL of aqueous solution, according to the liquid-solid ratio of 8:1, add 50g of smoke and dust for leaching, after 5 hours of reaction, solid-liquid separation, leaching liquid 300mL; among them, the concentration of Zn is 43.34g L -1 , Pb concentration 4.80g·L -1 , Cd concentration 7.50g L -1 , Fe concentration 13.70mg·L -1 ; During the leaching process, the Zn leaching rate was 94.5%, the Pb leaching rate was 91.7%, the Cd leaching rate was 93.8%, and the Fe leaching rate was 0.03%. The leachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com