Patents

Literature

81results about How to "Reduced corrosion protection requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling metal in waste LiMn1-x-yNixCoyO2 battery and preparing LiMn1-x-yNixCoyO2

ActiveCN104538695AImprove performanceReduce recycling costsCell electrodesWaste accumulators reclaimingHydrogen SulfateFiltration

A method for recycling metal in a waste LiMn1-x-yNixCoyO2 battery and preparing LiMn1-x-yNixCoyO2 comprises the steps that a waste lithium ion battery is discharged and dismantled, or positive electrode leftover materials and positive electrode fragments are collected, and waste positive plates are obtained; waste LiMn1-x-yNixCoyO2 powder is obtained through the calcinations, water dissolution and the filtration of the waste positive plates; the waste LiMn1-x-yNixCoyO2 powder and potassium pyrosulfate are mixed according to a certain proportion and calcinated, the calcinated products are leached by water, a potassium carbonate solution is added into the solution, then the filtration is carried out, the proportion of Li, Ni, Co and Mn in filter residues is adjusted by supplying carbonate, ball-milling, compressing and the calcinating are carried out on the Li, the Ni, the Co and the Mn, and LiMn1-x-yNixCoyO2 positive materials are regained. Composition adjustment is carried out on filtrate with sulfuric acid, and potassium hydrogen sulfate is obtained after the crystallization treatment is carried out.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

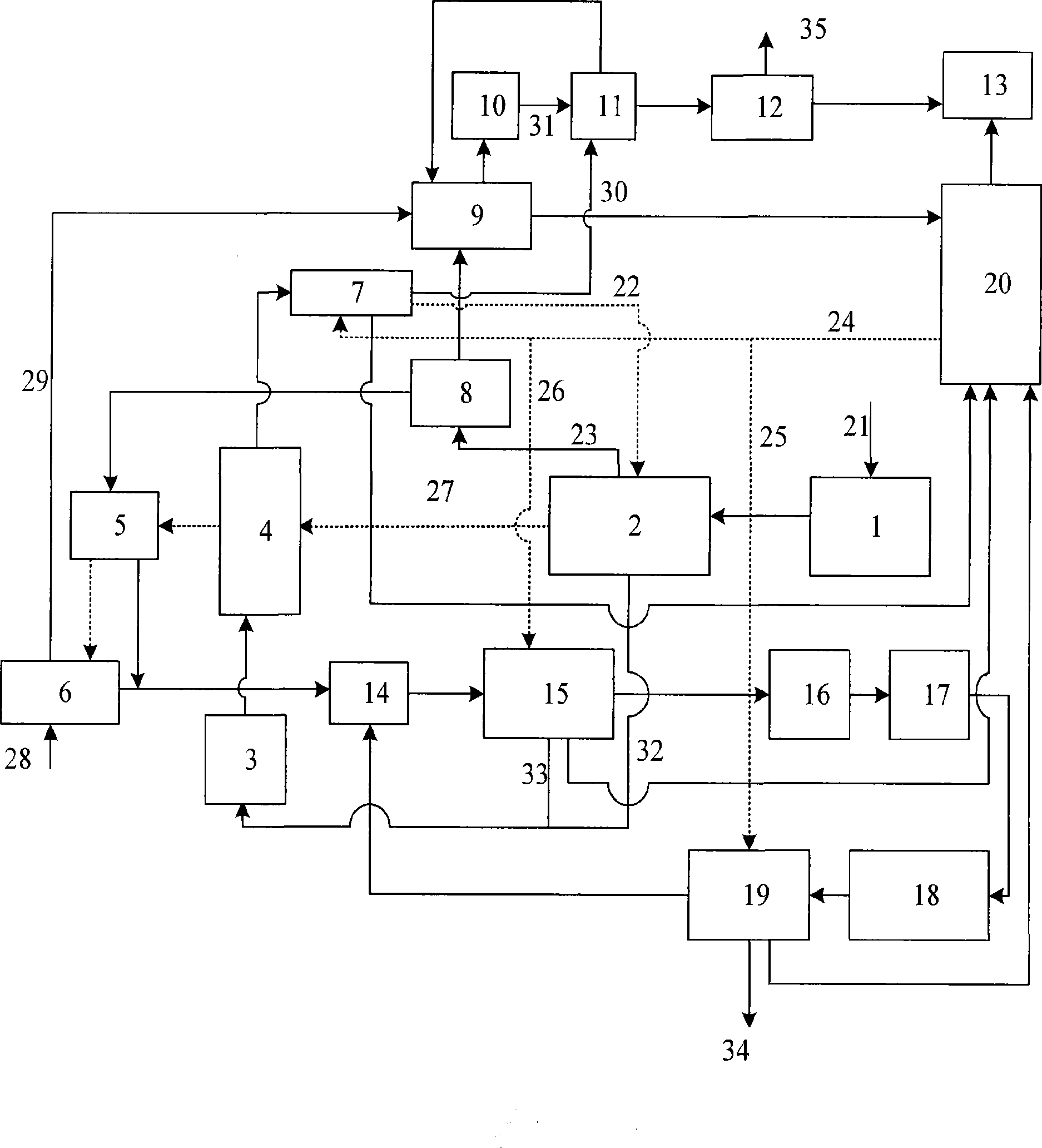

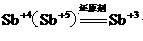

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

Production method of bamboo chemical dissolving pulp

ActiveCN101457494ASimple switching processHighly corrosiveWashing/displacing pulp-treating liquorsDigestersMaterial consumptionDissolving pulp

Aiming at the current situation of the cotton dissolving pulp and the wood dissolving pulp and the characteristics of the bamboo and the defects in the existing preparation of the dissolving pulp, the invention provides a method for preparing a chemical bamboo dissolving pulp. The chemical dissolving pulp produced can be widely applied in the cellulose derivative industries such as spinning viscose fiber, nitrocellulose and acetate fiber. The method comprises the following steps of: material preparation, cooking, screening, scrubbing, bleaching and paper making. The cooking procedure comprises two grades of cooking steps, wherein the primary cooking procedure is continuous cooking and the secondary cooking procedure is continuous cooking or intermittent cooking; and the bleaching procedure is elemental chlorine free bleaching or totally chlorine free bleaching. The invention solves the problems existed in the cooking and bleaching procedures. The chemical bamboo dissolving pulp can be prepared with high efficiency, low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

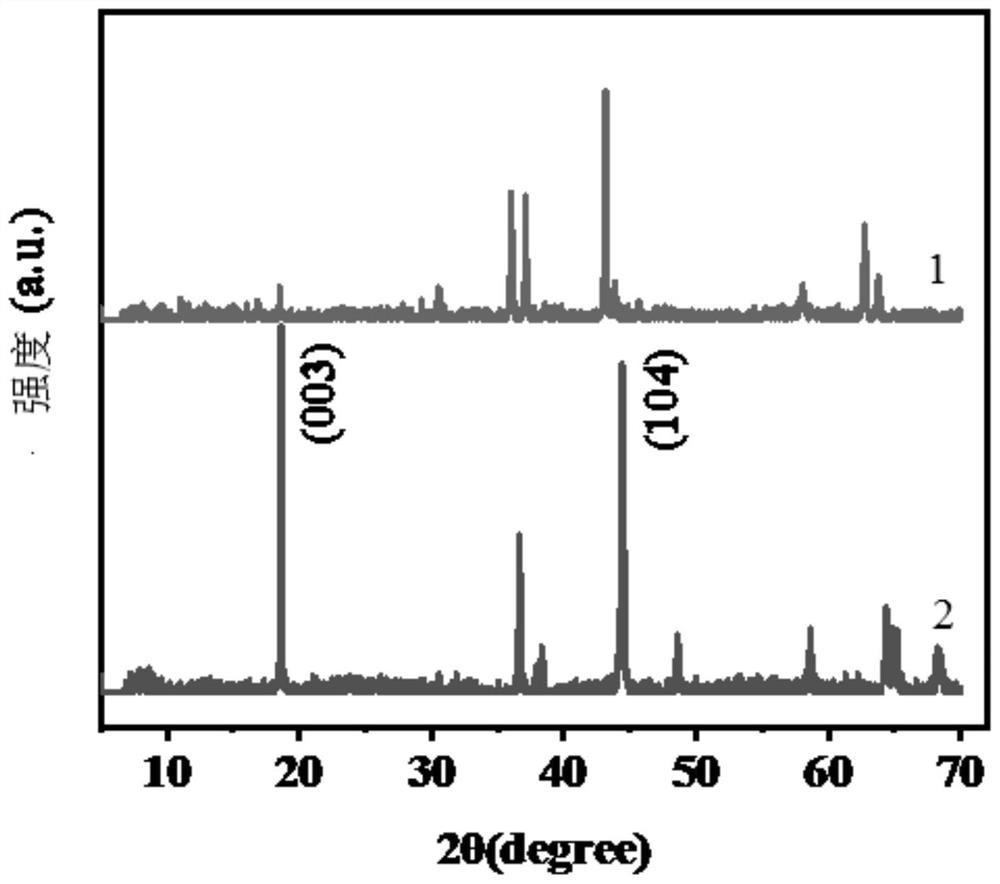

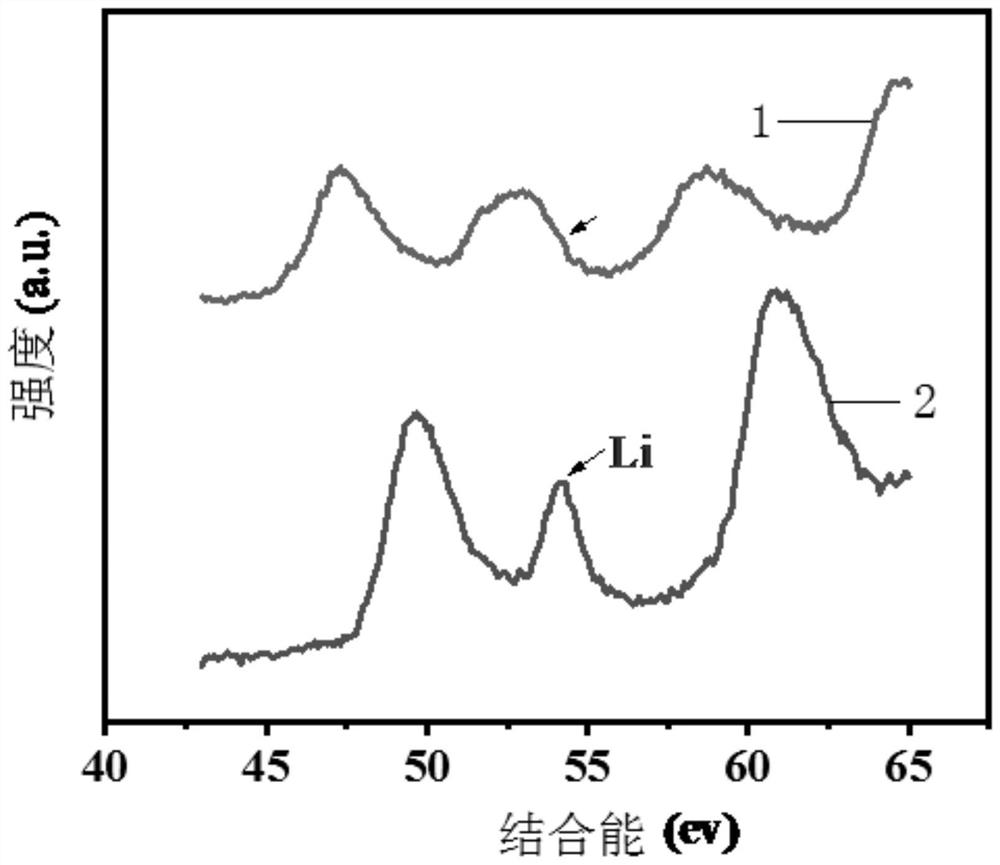

Method for regenerating positive electrode active material in LiNi1/3Co1/3Mn1/3O2 waste lithium ion battery

ActiveCN104466295AImprove performanceReduce recycling costsWaste accumulators reclaimingBattery recyclingHydrogen SulfateSodium bisulfate

The invention discloses a method for regenerating a positive electrode active material in a LiNi1 / 3Co1 / 3Mn1 / 3O2 waste lithium ion battery. The method includes the steps that the waste lithium ion battery is subjected to discharging and dismantling or positive pole leftover materials and positive electrode fragments are collected to obtain waste positive plates, and the waste positive plates are subjected to roasting, water dissolving and filtering to obtain waste LiNi1 / 3Co1 / 3Mn1 / 3O2 powder; the waste LiNi1 / 3Co1 / 3Mn1 / 3O2 powder and sodium pyrosulfate are roasted after being mixed according to a certain proportion, roasted products are leached by water, then a sodium carbonate solution is added into liquor, filtering is conducted, after the proportion of Li, Ni, Co and Mn in carbonate modulation filter residues is supplemented, the Li, Ni, Co and Mn are subjected to ball milling, compressing and roasting, and accordingly the LiNi1 / 3Co1 / 3Mn1 / 3O2 positive electrode material is obtained again. Components of filter liquor are adjusted through sulfuric acid, crystallization processing is carried out, and then sodium hydrogen sulfate is obtained.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for recovering cobalt lithium metal from waste lithium ion battery of lithium cobalt oxide positive material

ActiveCN104466292AHigh recovery rateShort processWaste accumulators reclaimingProcess efficiency improvementHydrogen SulfateLithium metal

The invention discloses a method for recovering cobalt lithium metal from a waste lithium ion battery of a lithium cobalt oxide positive material. The method comprises the following steps: discharging and disassembling the waste lithium ion battery to obtain a waste positive plate, roasting the waste positive plate, dissolving with water and filtering to obtain waste lithium cobalt oxide powder; mixing the waste lithium cobalt oxide powder and sodium hydrogen sulfate according to a certain proportion and then roasting; leaching the roasting product with water; adding sodium carbonate solution into the solution and then filtering; supplementing a certain quantity of lithium carbonate into filter residue and then performing ball milling, pressing and placing in a resistance furnace to roast to newly obtain the lithium cobalt oxide positive material with good electrochemical performance, wherein the ingredients of the filter liquor are adjusted by using sulfuric acid and the sodium hydrogen sulfate obtained after the crystallization treatment is performed can be reutilized.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

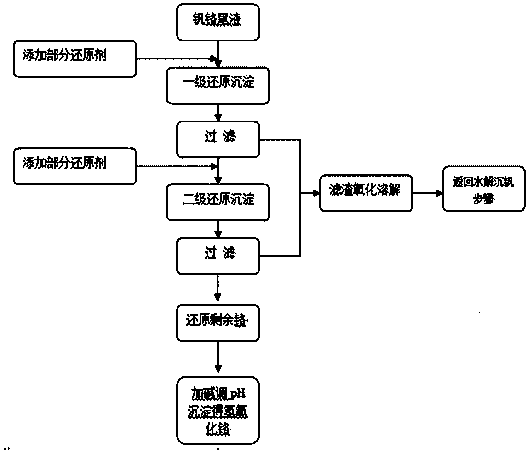

Method for precipitation separation and recovery of chromium and vanadium in chromium-vanadium solution

ActiveCN103849765AHigh removal rateLow Chromium Loss RateProcess efficiency improvementTwo stepReducing agent

The invention relates to a method for the precipitation separation and the recovery of chromium and vanadium in a chromium-vanadium solution. The method comprises the following steps: regulating the pH (Power Of Hydrogen) of a solution until the solution is acidic; adding an ammonium salt so as to precipitate the majority of vanadium from the solution in a form of ammonium polyvanadate; filtering and adding a certain amount of reducing agent into a vanadium-precipitated supernatant so as to perform reduction and precipitation on the partial vanadium in the solution; stirring and filtering; then adding the certain amount of reducing agent so as to reduce the rest of the vanadium in the precipitation solution; filtering; collecting filter residues obtained by two steps of reduction and precipitation; dissolving out in an oxidization manner and returning to the vanadium precipitation step via the ammonium salt; collecting the supernatants obtained by the two steps of reduction and precipitation; adding the certain amount of reducing agent again and precipitating chromium hydroxide; and filtering and calcining a filter cake so as to prepare chromium sesquioxide, wherein the supernatant after the precipitation of the chromic hydroxide can be taken as a mother liquor of a leaching process to be recycled. The method is simple in process, low in cost, less in equipment and small in reagent adding amount, and realizes the recycling of wastewater.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

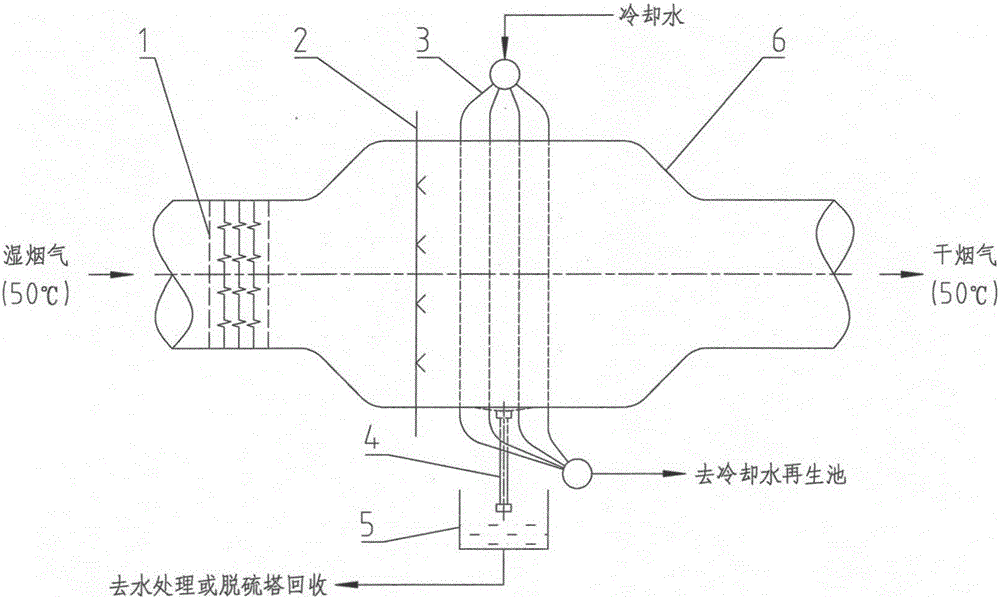

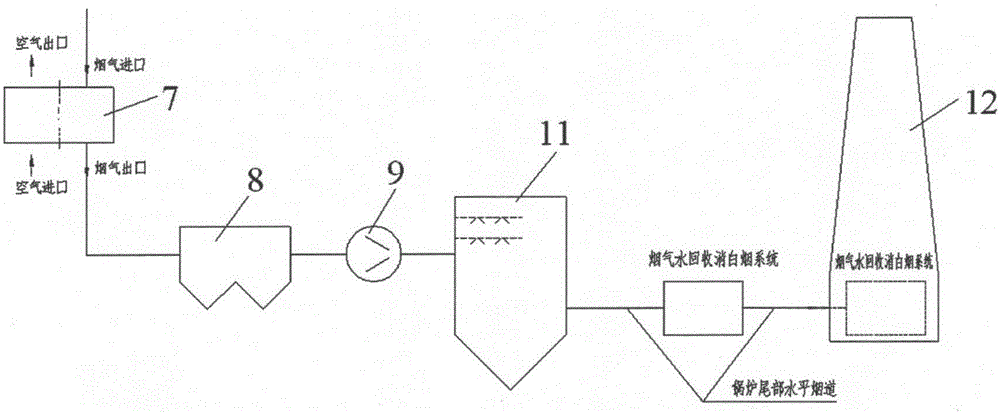

Exhaust gas water recycling and white smoke eliminating system through condensation method

InactiveCN105709573AReduce resistanceReduce energy consumptionGas treatmentLighting and heating apparatusEnvironmental engineeringEngineering

The invention discloses an exhaust gas water recycling and white smoke eliminating system through a condensation method. The system is characterized by comprising an exhaust gas condensation chamber; a condensation pipe bundle is arranged at an inlet of the exhaust gas condensation chamber, a water flushing device is arranged on one side of the condensation pipe bundle, and a condensation water draining device is arranged at the lower portion of the condensation pipe bundle. By adopting the exhaust gas water recycling and white smoke eliminating system, water recycling and utilization are performed before wet purified exhaust gas is exhausted from a wet-type desulfuration tower, the gypsum component is recycled along with water, the total amount of gypsum rain and aerosol drained to air can be effectively lowered fundamentally, the exhausted exhaust gas temperature is lowered slightly, exhaust gas is exhausted in a dried mode, the white smoke phenomenon at an outlet of a chimney can be greatly reduced, and the effect of eliminating white smoke and gypsum rain can be achieved when no exhaust gas heating device is adopted.

Owner:SHANGHAI BOILER WORKS

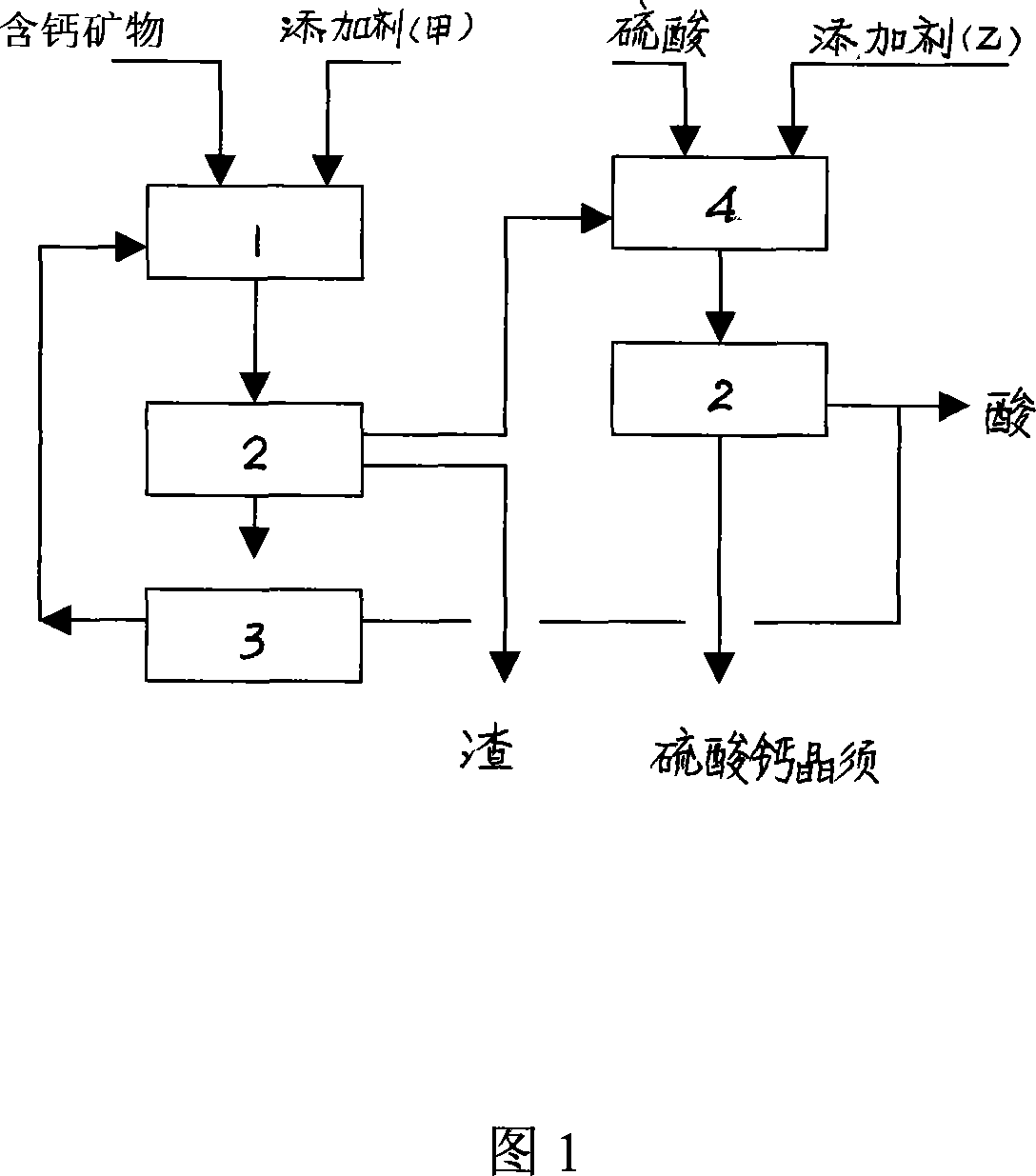

Method for preparing crystal whisker of calcium sulphate, and phosphonic acid

InactiveCN101092734AImprove decomposition rateReduce in quantityPolycrystalline material growthFrom normal temperature solutionsDecompositionFiltration

This invention discloses a method for preparing calcium sulfate whiskers and phosphoric acid. The method comprises: phosphate ore decomposition, slurry filtration and separation, calcium sulfate whisker crystallization, separating, washing and drying. The method adds composite additive A during the during phosphate ore decomposition process, and adds composite additive B during calcium sulfate whisker crystallization process to form calcium sulfate whiskers and phosphoric acid. Composite additive A is composed of humic acid and diatomite at a ratio of 1:(2-10). Composite additive B is composed of sodium dodecyl sulfonate and sulfate or phosphate of magnesium and aluminum at a ratio of (2-5):1. The addition amount of composite additive A is 0.5-5.0% of phosphate ore. The addition amount of composite additive B is 0.1-2.0% of theoretical formation amount of calcium sulfate whiskers. The method has such advantages as adequate utilization of raw materials, low solid waste discharge amount, and low production cost.

Owner:云南常青树化工有限公司

Method for separating quartz from low-grade potassium and sodium feldspar ore

ActiveCN105618271ALower surface oxidation potentialIncrease the surface contact angleFlotationPhysical chemistryPotassium

The invention provides a method for separating quartz from low-grade potassium and sodium feldspar ore. The method comprises the steps of providing low-grade potassium and sodium feldspar ore powder; mixing the low-grade potassium and sodium feldspar ore powder and water for obtaining low-grade potassium and sodium feldspar ore slurry; adjusting the pH value of the low-grade potassium and sodium feldspar ore slurry to 8-10 through conditioning agents, and then carrying out roughing, scavenging, concentrating and drying on the low-grade potassium and sodium feldspar ore slurry for obtaining fine potassium and sodium feldspar powder and floating the quartz; adding activating agents, inhibitors and amine collecting agents in the roughing process and the scavenging process each time. The method has the advantages that the production cost is low, the requirement for corrosion prevention of equipment is low, pollution to the environment is small, and the quality of the obtained fine potassium and sodium feldspar powder meets the use standard GB / T9195-1999 of the ceramic industry.

Owner:ZHENGZHOU SHANCHUAN HEAVY IND CO LTD

Method for recycling metal from waste Ni-Co lithium manganate battery

ActiveCN104466294AHigh recovery rateReduce recycling costsWaste accumulators reclaimingBattery recyclingHydrogen SulfateFiltration

A method for recycling metal from a waste Ni-Co lithium manganate battery comprises the following steps that the waste Ni-Co lithium manganate battery is discharged and disassembled or positive electrode scrap and positive electrode fragments are collected, a waste positive plate is obtained, calcination, dissolution and filtration are conducted on the waste positive plate, and then waste Ni-Co lithium manganate powder is obtained; the waste Ni-Co lithium manganate powder and potassium hydrogen sulfate are mixed according to a certain proportion and then calcined, a calcined product is leached through water, a potassium carbonate solution is added into a solution, filtration is conducted, carbonate is supplemented to adjust the proportion of Li, Ni, Co and Mn in a filter residue, ball grinding, compression and calcination are conducted on the filter residue, and the Ni-Co lithium manganate positive electrode material is obtained again. Constituent adjustment is conducted on filtrate through sulfuric acid, and potassium hydrogen sulfate obtained after crystallization can be reused.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

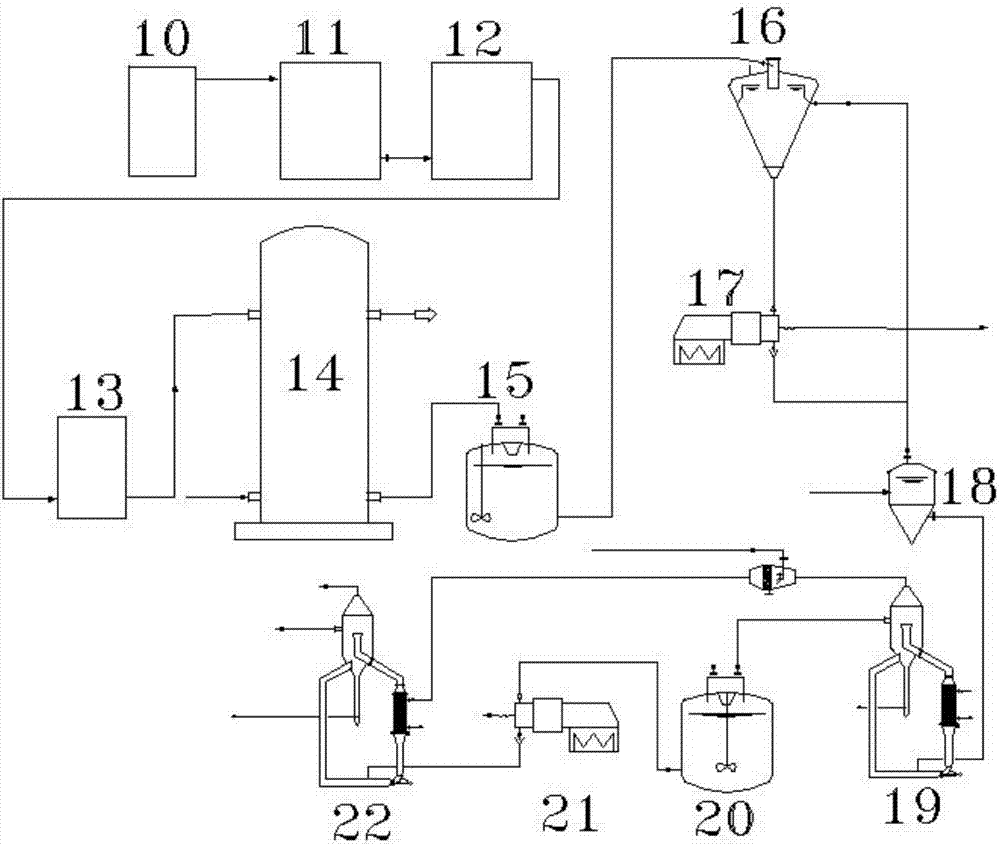

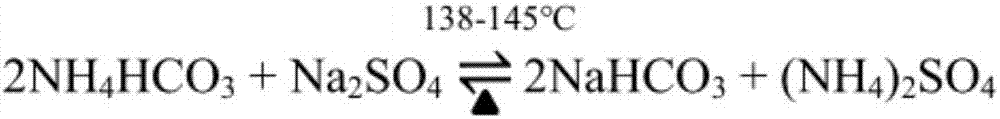

Method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine

ActiveCN106865571ASolve processing problemsAchieve recyclingAlkali metal carbonatesAmmonia compoundsSodium bicarbonateProcess engineering

Belonging to the technical field of solid waste miscellaneous salt recycling treatment, the invention discloses a method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine. According to the method, evaporated and concentrated chemical strong brine is subjected to hardness removal to obtain a delicate mirabilite solution, and then ammonia-soda process reaction is carried out to obtain sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the difficult treatment problem of chemical strong brine, realizes recycling of miscellaneous salt in strong brine, and meets the sustainable development requirements. At the same time, compared with the salt method for preparation of sodium bicarbonate, the method provided by the invention reduces the anti-corrosion requirement of equipment, saves the project investment for preparation of sodium bicarbonate, has the byproduct ammonium sulfate with a value higher than ammonium chloride, and has obvious advantages in economic benefits.

Owner:科莱环保(北京)有限公司

Repair and regeneration method for lithium cobaltate positive active material in waste lithium ion battery

ActiveCN104485493AImprove performanceShort processWaste accumulators reclaimingBattery recyclingHydrogen SulfateLithium carbonate

The invention discloses a repair and regeneration method for a lithium cobaltate positive active material in a waste lithium ion battery. The method comprises the following steps: discharging the waste lithium ion battery, dismantling to obtain a waste positive plate, roasting the waste positive plate, dissolving in water, and filtering to obtain waste lithium cobaltate powder; mixing the waste lithium cobaltate powder with potassium pyrosulfate according to a certain ratio, roasting, leaching a roasted product by the water, adding a potassium carbonate solution into a leaching solution, filtering, supplementing a certain amount of lithium carbonate into filter residues, performing ball-milling, compacting, and roasting in a resistance furnace to obtain the lithium cobaltate positive material with good electrochemical performance, wherein filter liquor is subjected to component adjustment by sulfuric acid and then crystallized to obtain potassium hydrogen sulfate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

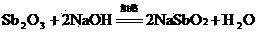

Method for preparing sodium antimonate from antimony oxide ore via alkaline approach

ActiveCN103866121AHigh recovery rateWaste residue is non-toxic and harmlessProcess efficiency improvementLeaching rateAntimony oxide

The invention discloses a method for preparing sodium antimonate from an antimony oxide ore via an alkaline approach. The method comprises the following steps: (1) leaching the antimony oxide ore, (2) purifying filtrate, and (3) oxidizing the purified filtrate. The method is high in recovery rate, the leaching rate of antimony is 95-99%, the direct recovery rate of sodium antimonate is 90-95%, the whole process is performed under an alkaline environment, the requirement on corrosion resistance of equipment is not high, no complicated pretreatment is required in the process, the needed raw materials are nontoxic and harmless, the alkaline liquid is recyclable, neither waste water nor waste gas is generated in the process, and waste residues are nontoxic and harmless.

Owner:锡矿山闪星锑业有限责任公司

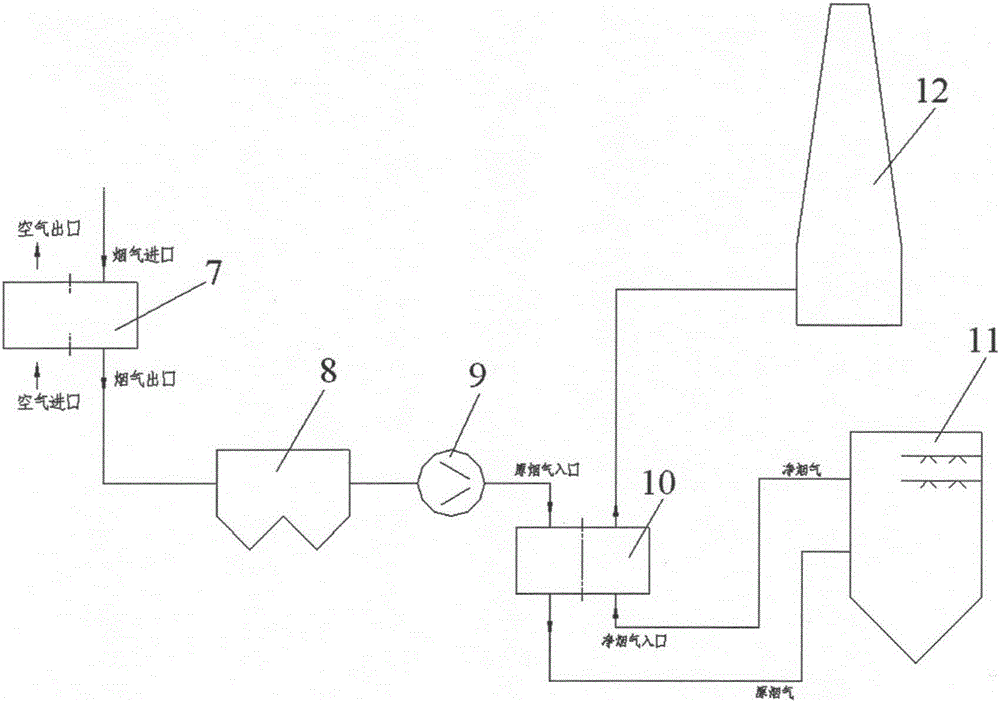

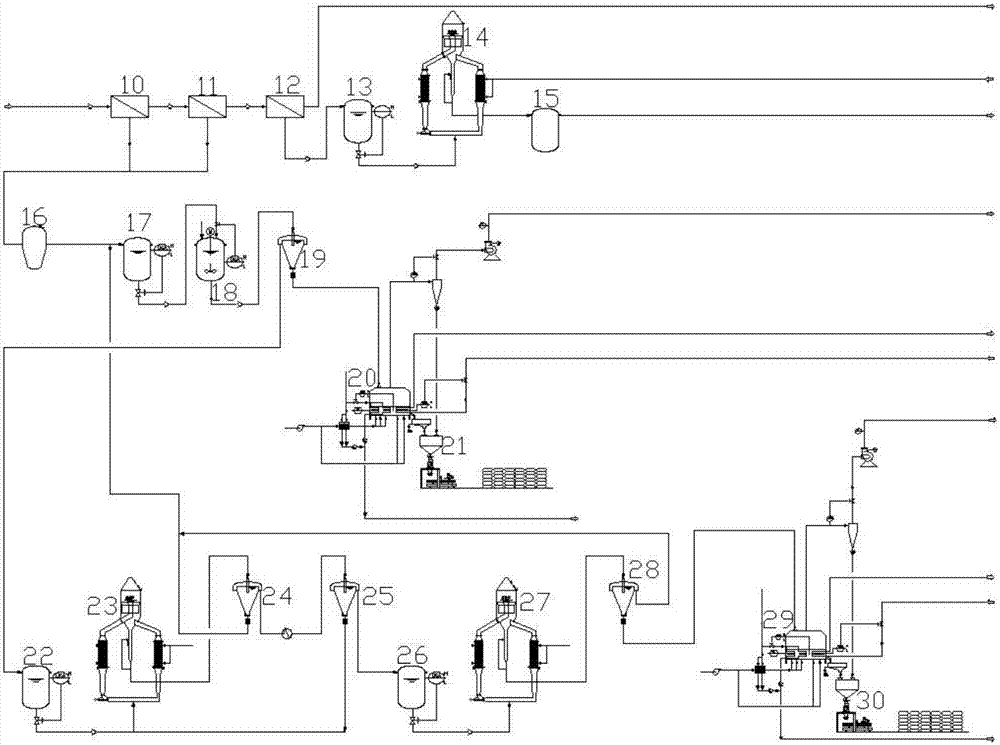

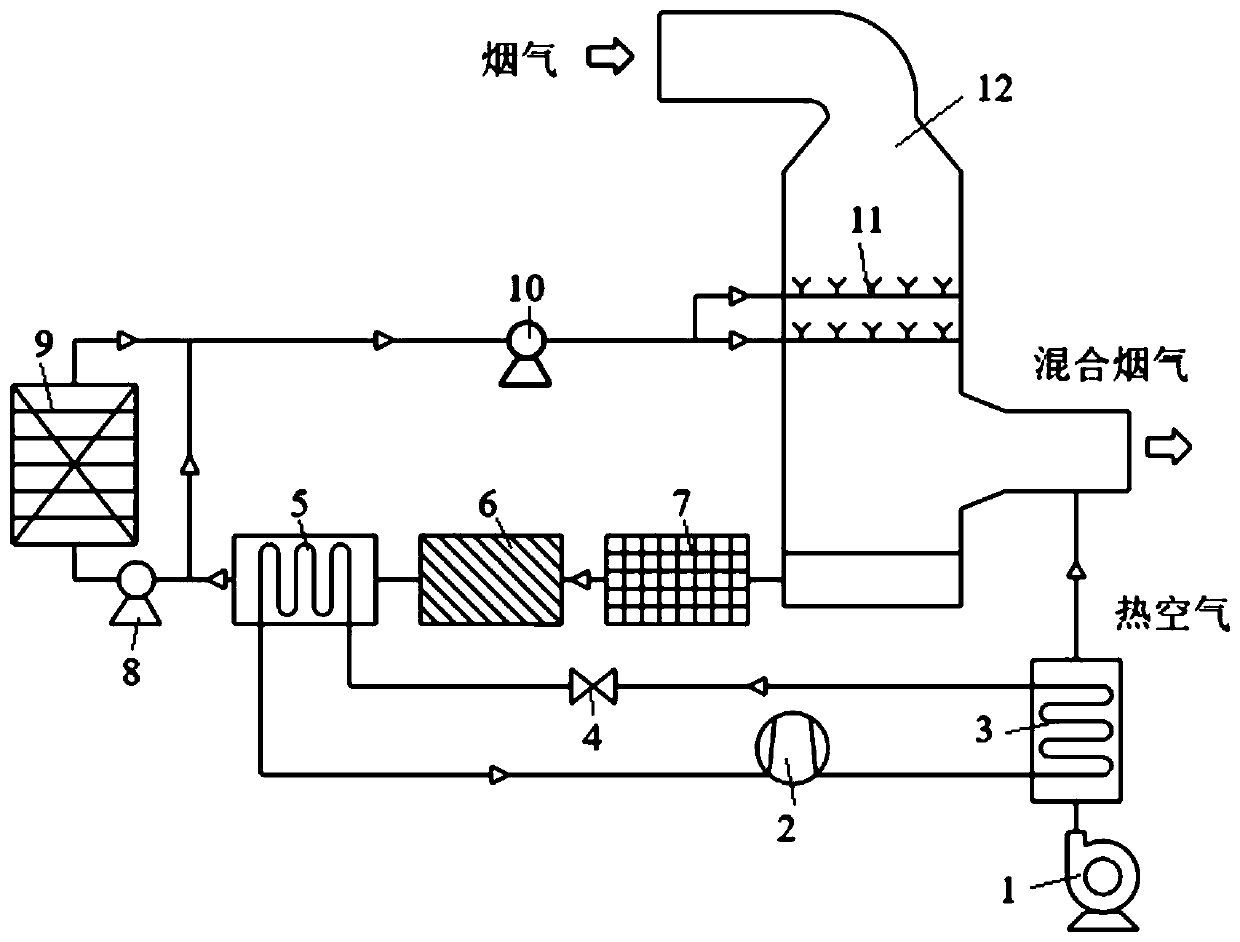

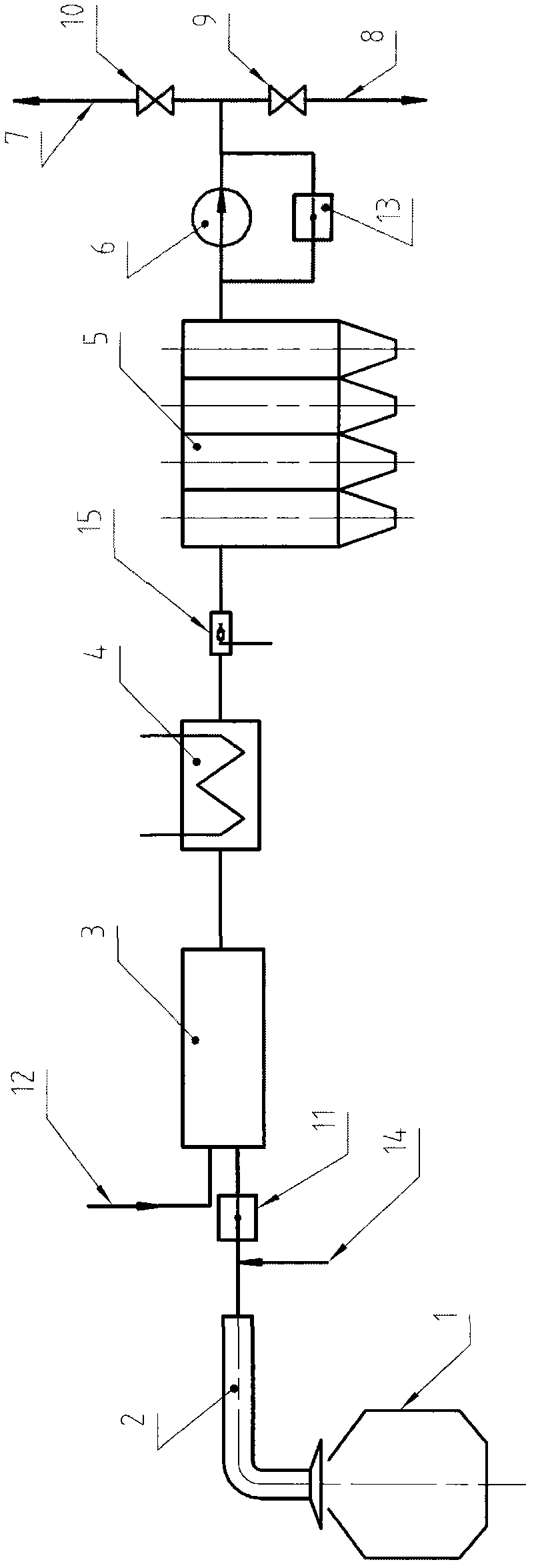

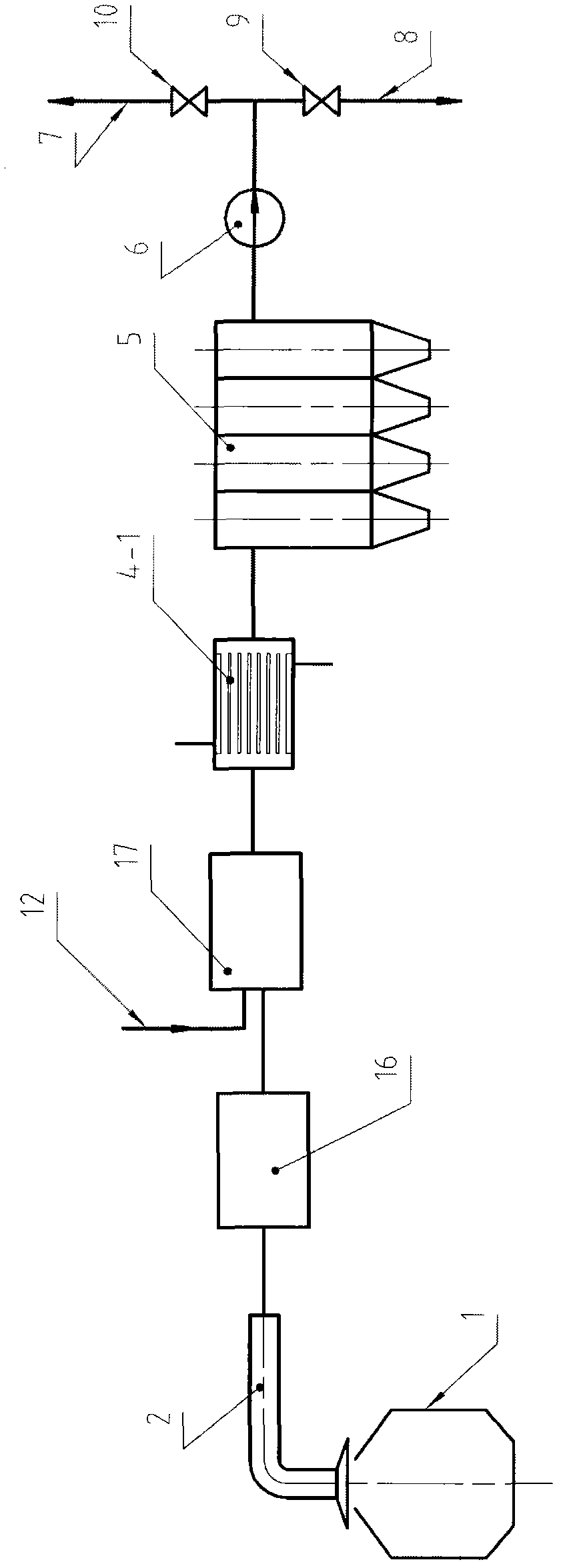

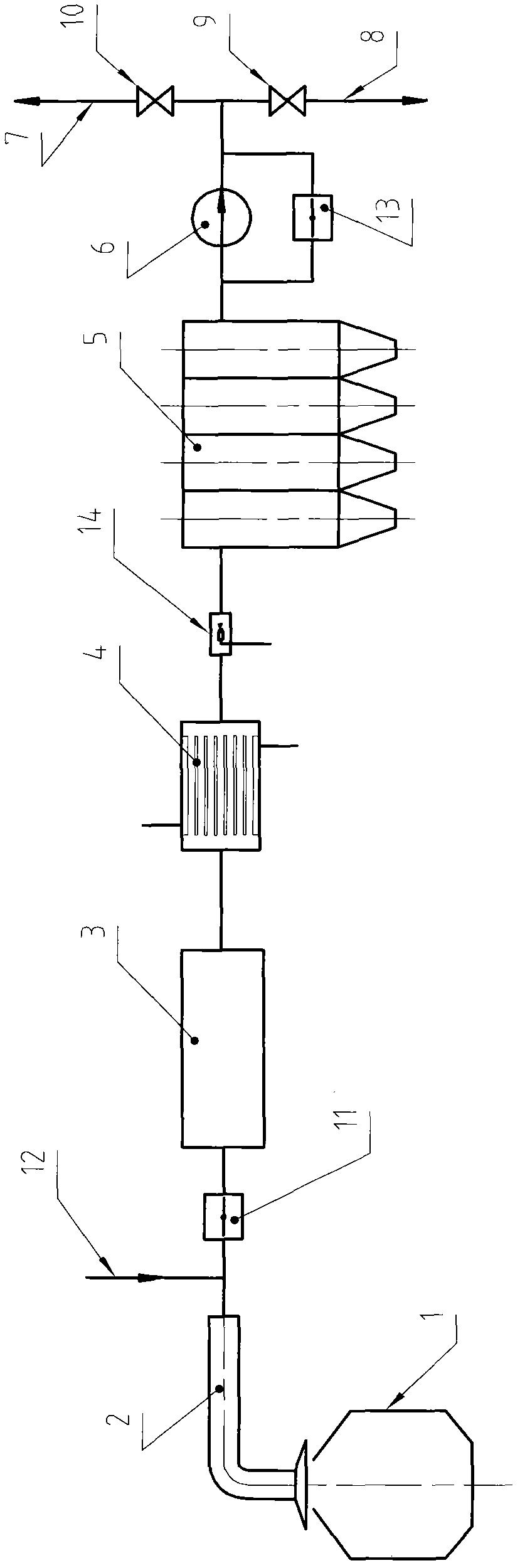

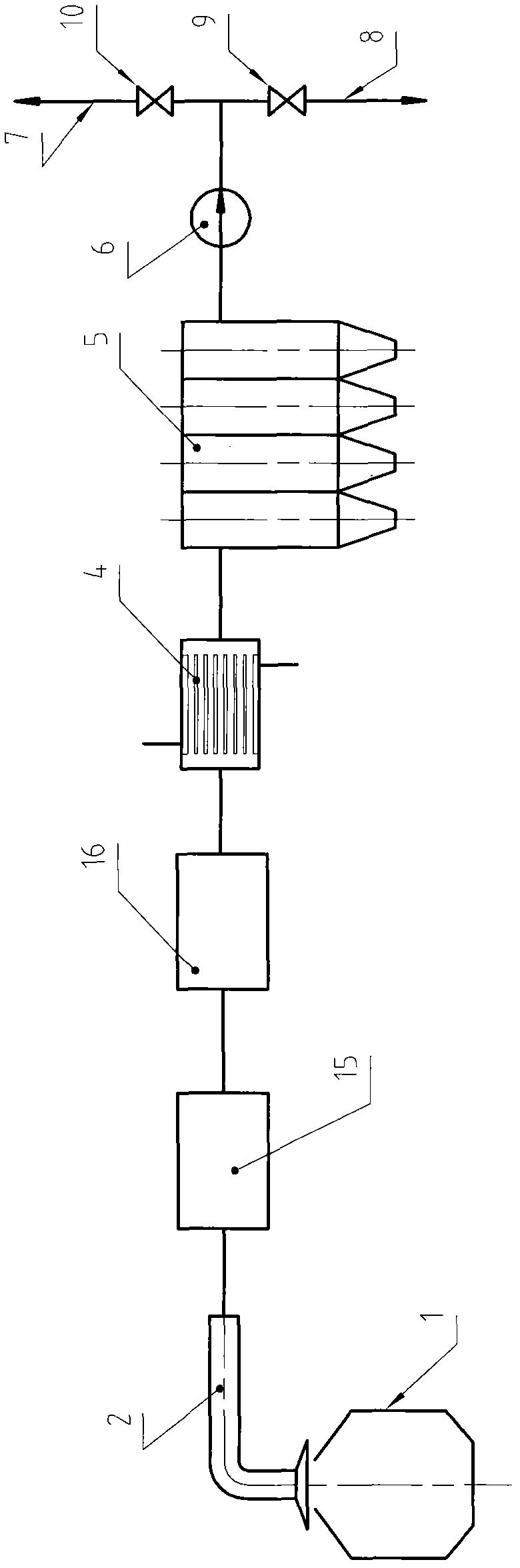

Grate-kiln SNCR/SCR (selective non-catalytic reduction/selective catalytic reduction) denitration and active coke desulfurization combined system and grate-kiln SNCR/SCR denitration and active coke desulfurization combined process

PendingCN109794146AReduce escapeImprove denitrification efficiencyDispersed particle separationMixed gasToxic industrial waste

The invention belongs to the technical field of industrial waste gas control, and relates to a grate-kiln SNCR / SCR (selective non-catalytic reduction / selective catalytic reduction) denitration and active coke desulfurization combined system. A denitration reductant injector of an SNCR system is communicated with one side, close to a rotary kiln, of a preheating section II; the preheating section II is communicated with an SCR system, and the SCR system is communicated with a drying section II; the drying section II and a preheating section I are communicated with an active coke desulfurizationand adsorption tower. The invention also provides a grate-kiln SNCR / SCR denitration and active coke desulfurization combined process. Flue gases of the rotary kiln enter the preheating section II, and the SNCR system sprays ammonia water into the flue gas inlet side of the preheating section II for denitration; the flue gases enter the SCR system for denitration, and then enter the drying sectionII to be mixed with the flue gases of the drying section I; the mixed gases enter the active coke desulfurization and adsorption tower for desulfurization after passing through an electric dust remover, a main exhaust fan and a flue gas heat exchanger. The grate-kiln SNCR / SCR denitration and active coke desulfurization combined system and the grate-kiln SNCR / SCR denitration and active coke desulfurization combined process have the advantages of improved denitration efficiency, reduced cost, high desulfurization and dust removal efficiency, and capability of meeting ultra-clean requirements.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Method for comprehensive treatment of chemical strong brine

InactiveCN106865859AReduce the amount of treated waterReduce energy consumptionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentSodium bicarbonateEconomic benefits

Belonging to the technical field of resource recycling, the invention discloses a method for comprehensive treatment of chemical strong brine. According to the method, chemical strong brine is separated by a nanofiltration membrane to obtain a sodium chloride solution and a sulfuric acid solution, the sulfuric acid solution is then subjected to nitrate freezing purification in a cold way, then the product reacts with ammonia water and carbon dioxide gas to prepare sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the problem of difficult treatment of chemical strong brine, realizes recycling of miscellaneous salts in strong brine, and satisfies the requirements of sustainable development. At the same time, compared with salt method for preparation of sodium bicarbonate, the method can reduce the anticorrosion requirement of equipment and save the project investment for preparation of sodium bicarbonate, the byproduct ammonium sulfate has a value higher than ammonium chloride, thus having obvious advantages in economic benefit.

Owner:科莱环保(北京)有限公司

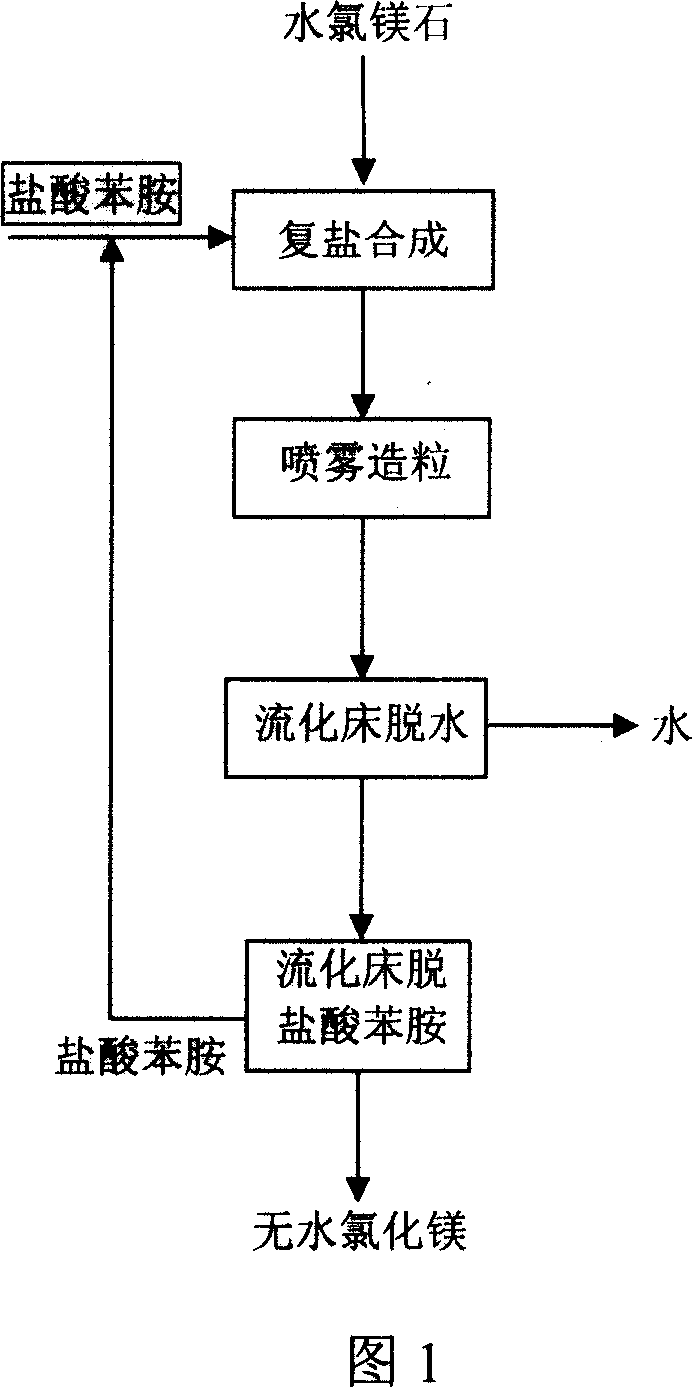

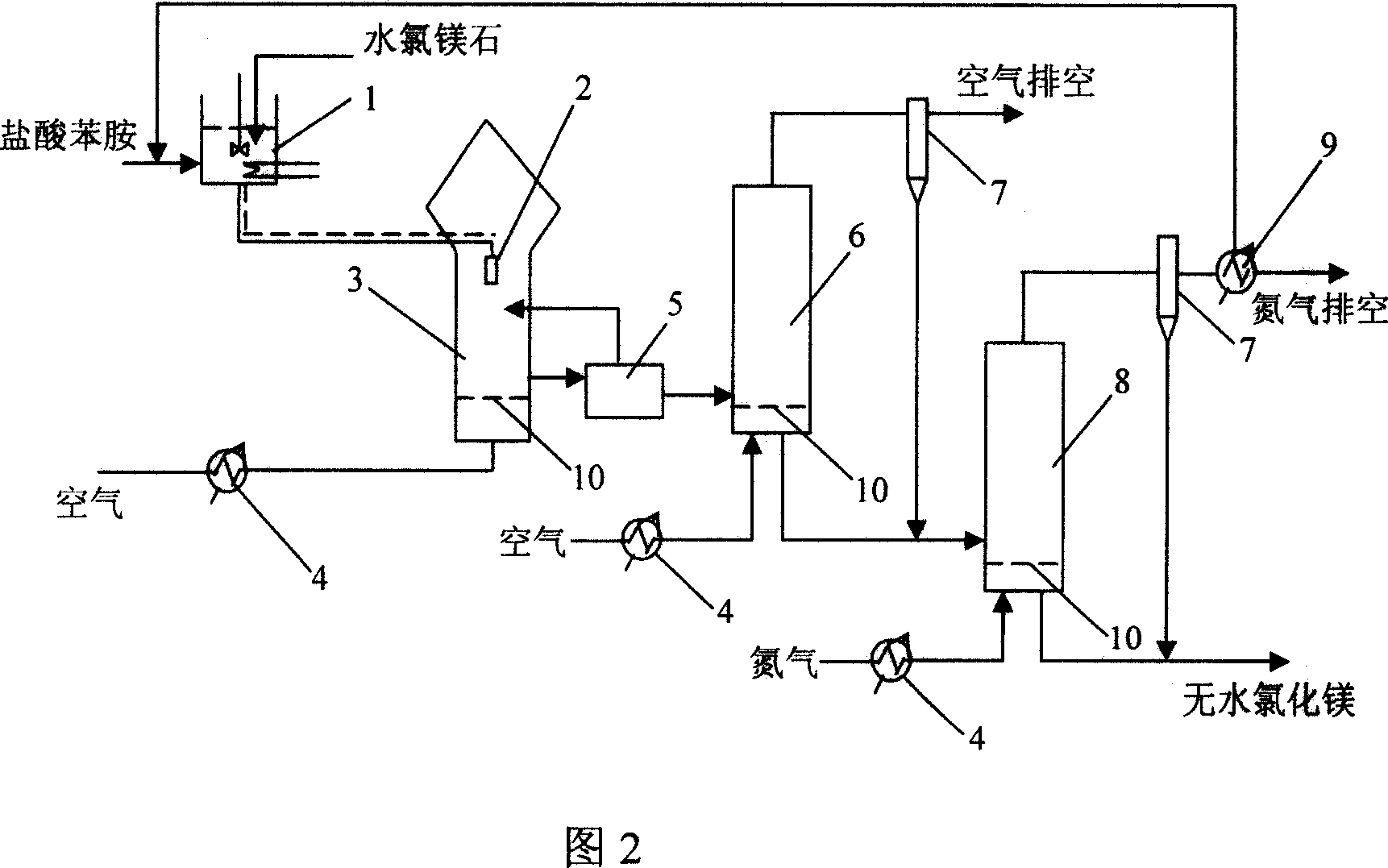

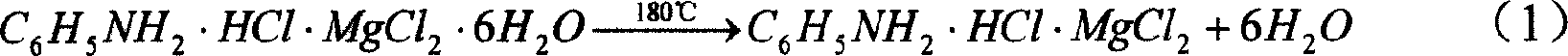

Process for preparing anhydrous magnesium chloride by dewatering bischofite

InactiveCN1944261ASimple structureEasy to manufactureMagnesium chloridesFluidized bedMagnesium chloride hexahydrate

The present invention relates to chemical and metallurgical technology, and is especially process of preparing anhydrous magnesium chloride through dewatering bischofite. The process includes the first reaction of aniline hydrochloride and bischofite to produce aniline hydrochloride-magnesium chloride hexahydrate complex salt, the subsequent spray drying and pelletizing the complex salt, and final eliminating crystallized water and aniline hydrochloride in a fluidized bed to obtain the anhydrous magnesium chloride product. The present invention has the advantages of low power consumption, simple technological process, easy industrial amplification, environment friendship, stable product quality, etc.

Owner:TSINGHUA UNIV

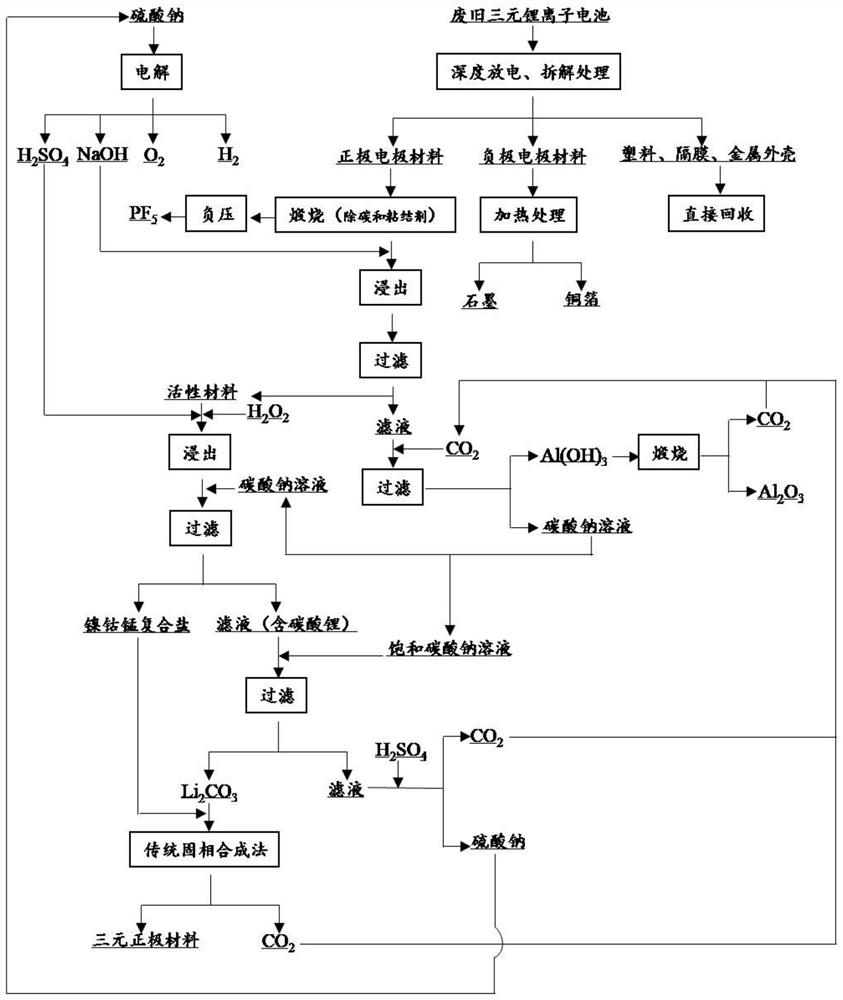

Waste ternary power lithium ion battery environmental-friendly recovery method based on electrolysis of sodium sulfate

ActiveCN111778401AAchieve cycleFriendlyElectrolysis componentsWaste accumulators reclaimingElectrolysisEnvironmental engineering

The invention relates to a waste ternary power lithium ion battery environmental-friendly recovery method based on electrolysis of sodium sulfate. The method primarily comprises the following steps of1) disassembling and pre-treating a ternary power lithium ion battery; 2) removing an organic phase and a binder; 3) electrolyzing sodium sulfate to prepare sulfuric acid and sodium hydroxide solutions; 4) carrying out precipitation separation on aluminum in the power lithium ion battery; 5) leaching electrode material powder; and 6) precipitating and recovering nickel, cobalt, manganese and lithium. The invention provides the waste ternary power lithium ion battery environmental-friendly recovery method based on electrolysis of sodium sulfate. By taking acid and alkali solutions produced byelectrolysis of sodium sulfate as a leaching agent, valuable metals in the waste ternary power lithium ion battery are recycled comprehensively, and in the whole process, strong acids and alkali are not used, so that waste liquor is not generated and the method is green and environmental-friendly.

Owner:CHANGZHOU UNIV

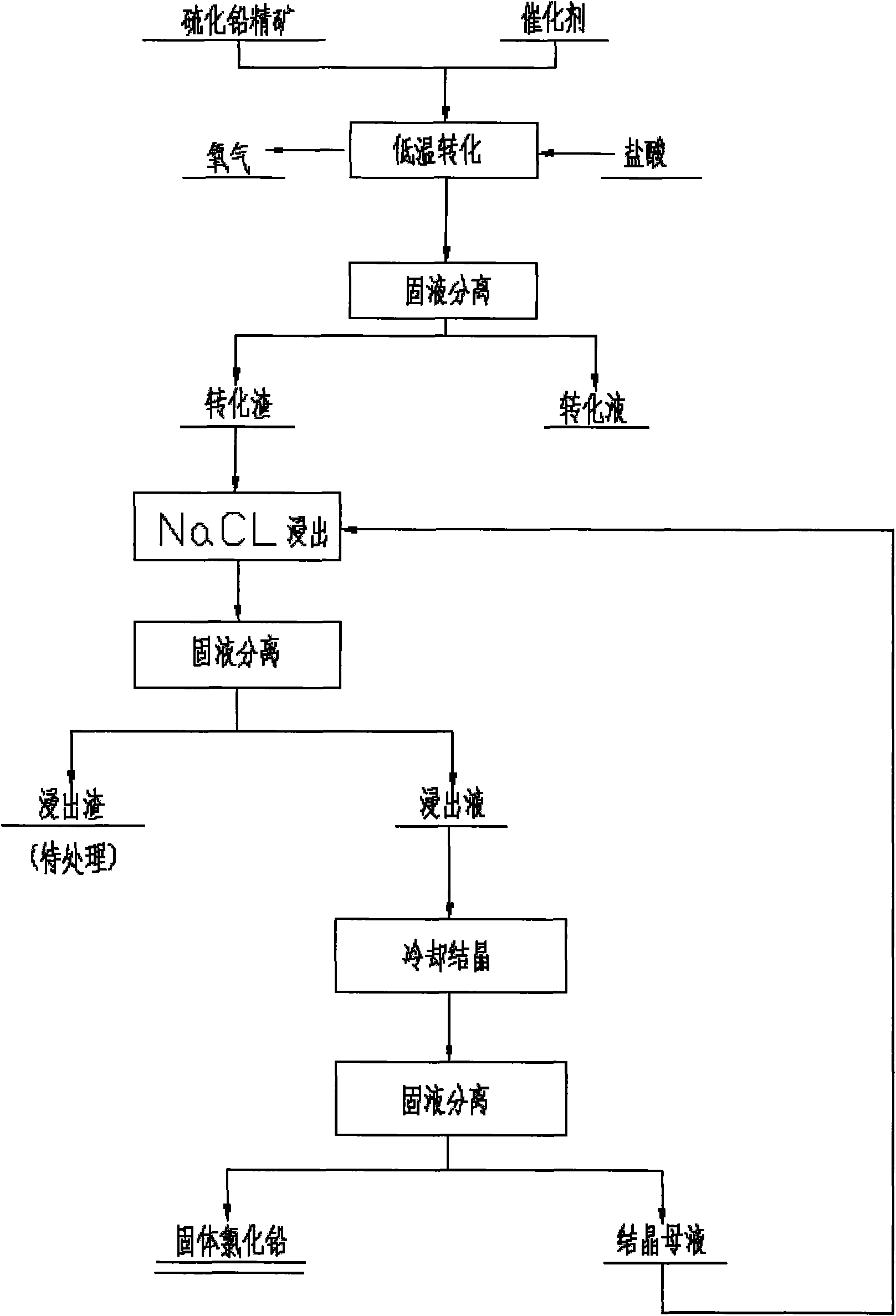

Method for extracting lead from lead sulfide ore concentrate by HCl-O2-NaCl system

InactiveCN101619389ARaise the gradeNo pollution in the processProcess efficiency improvementSlagLead sulfide

The invention relates to a method for producing rough lead by the direct low temperature melting of solid lead chloride. The method is characterized by comprising the following steps: (1) firstly, mixing solid lead chloride, fusing agent and reducing agent; (2) adding the mixture into a turning short kiln to carry out low-temperature smelting so as to produce rough lead, slag, flue dust and flue gas; (3) carrying out water leaching on the slag and the flue dust produced by the low-temperature smelting, producing leached slag and leached fluid by solid and fluid separation, keeping the leached slag to be processed, evaporating and concentrating the leached fluid and producing the solid lead chloride. The fusing agent used by the invention is calcium carbonate, and the reducing agent used by the invention is coke powder or coal powder. The invention has the characteristics of low production cost, energy consumption and flue dust rate, high efficiency and lead direct yield, less lead volatilizing content, and the like.

Owner:SHENYANG RES INST OF NONFERROUS METALS +1

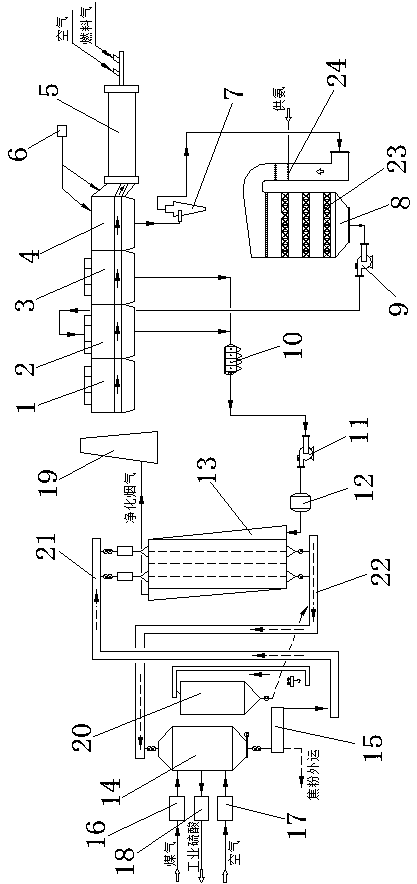

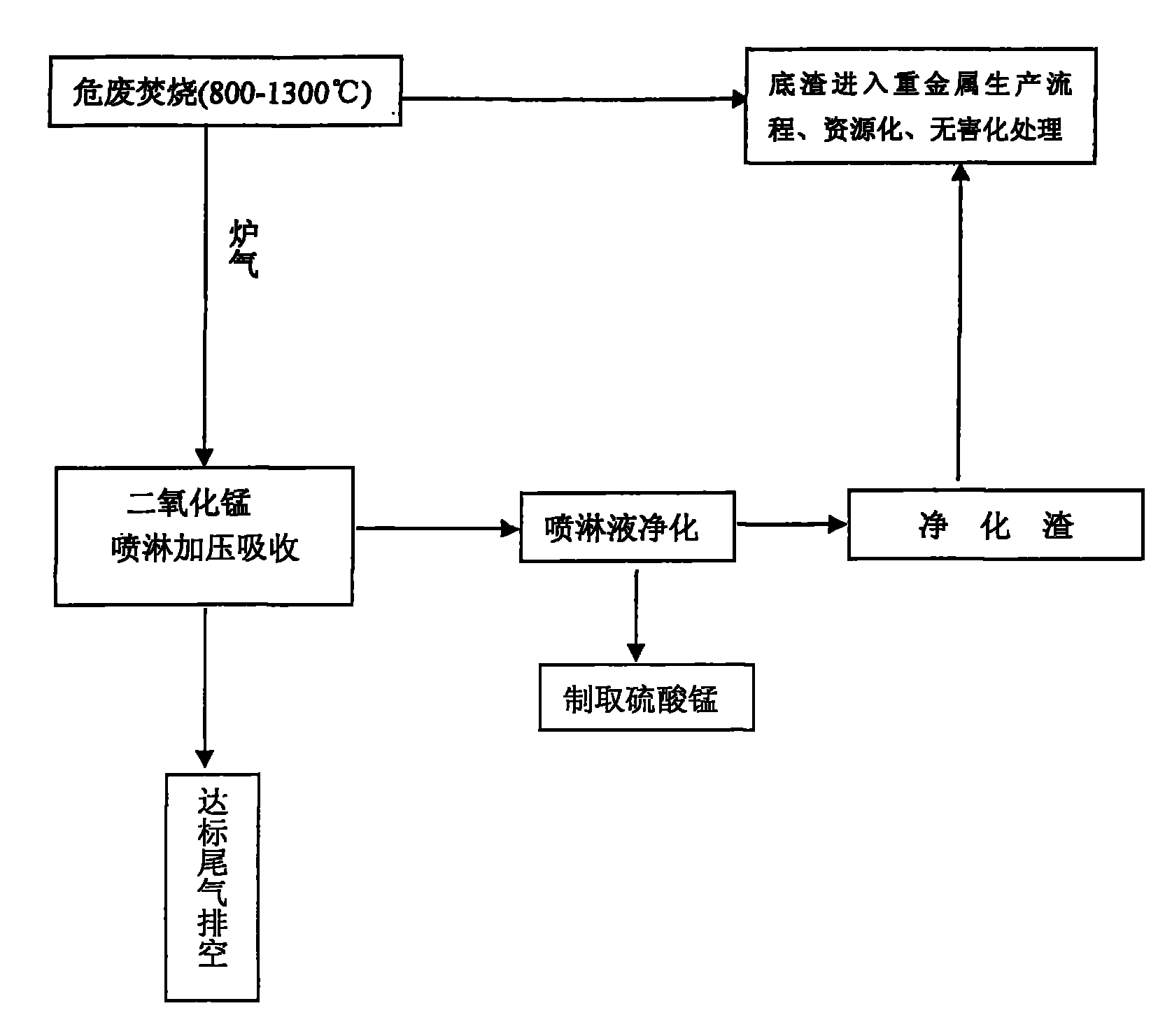

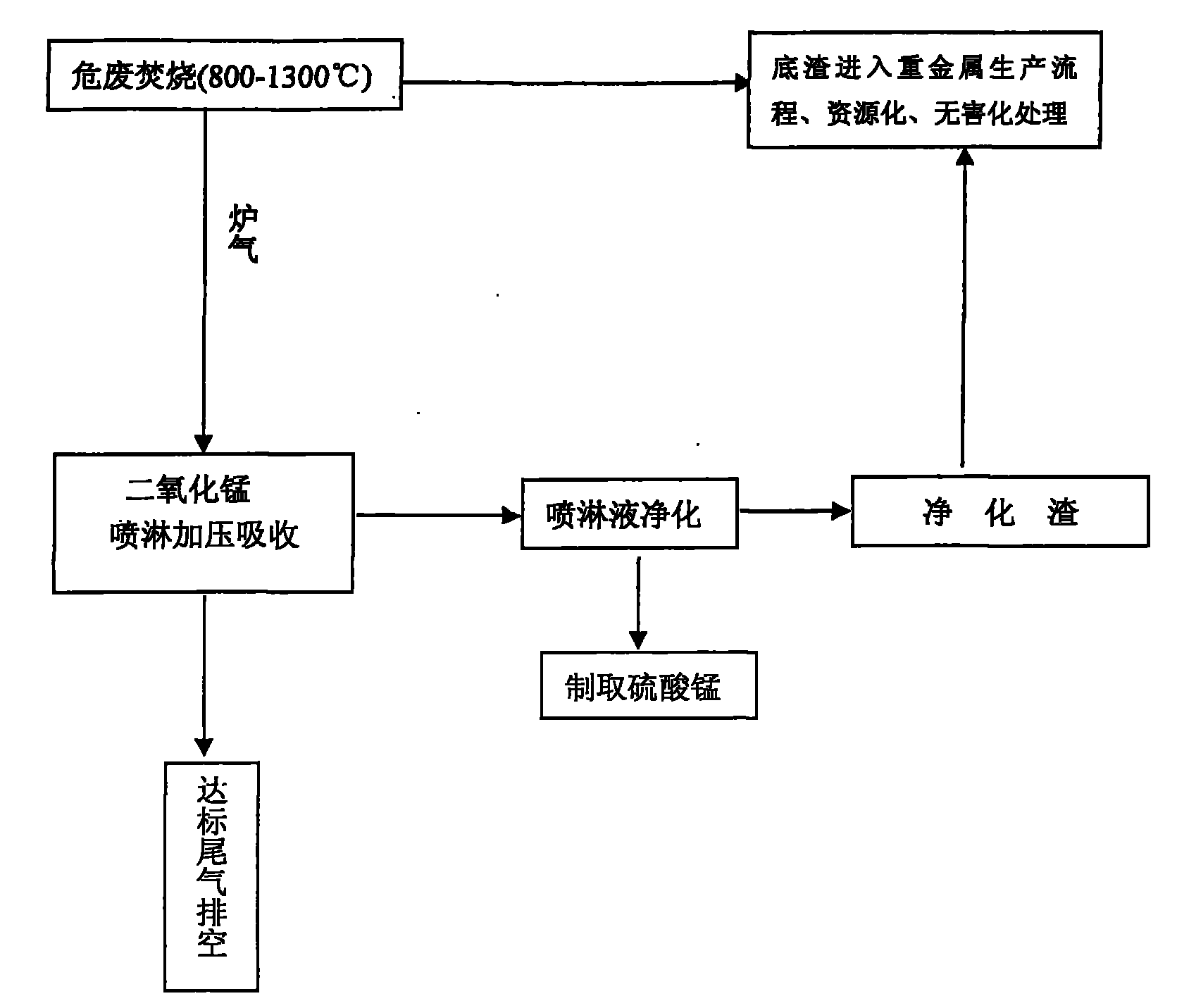

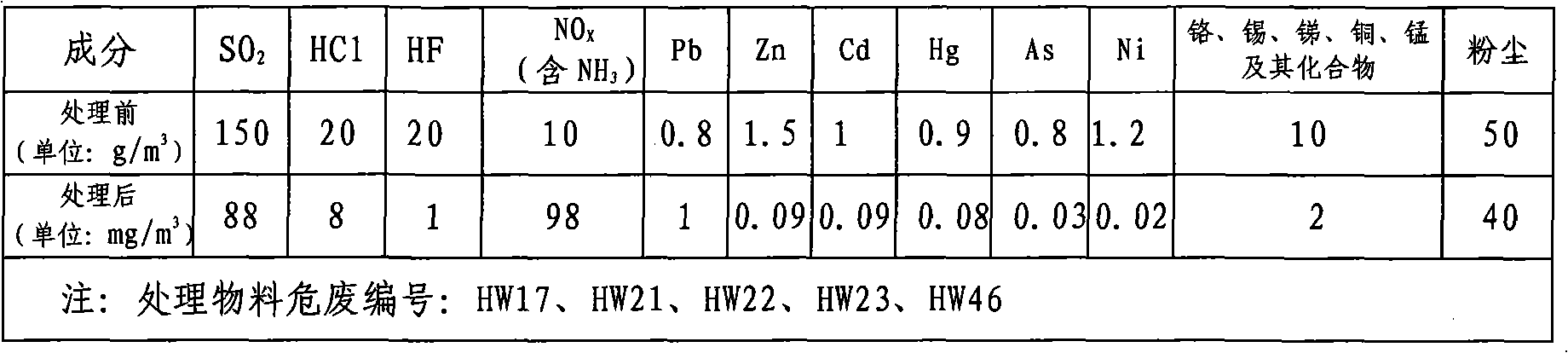

Method for treating incineration tail gas of solid hazardous waste

InactiveCN101785967AReduced corrosion protection requirementsAbsorb running cost reductionDispersed particle separationHazardous substanceEngineering

The invention discloses a method for treating incineration tail gas of solid hazardous waste, comprising the following steps of: (1) taking manganese dioxide as the oxidant, adding water to prepare a sizing agent; (2) delivering the size into the smoke absorption tower, spraying the sizing agent in mist, wherein the pressurized smoke with the wind pressure of 1500-5000Pa is introduced from the bottom of the tower, the gas inlet tubes are dispersed tubes under the liquid level of the sizing agent, wherein the temperature T of the tower bottom recovery liquid is controlled to be not below 5 DEG C and not above 90 DEG C, and the pH value is not less than 3.8; (3) separating the precipitation from the recovery liquid at the tower bottom, preparing manganese sulfate via the solution, and recovering the heavy metal from the bottom dross; (4) discharging the tail gas which is up to the standard. The method for treating incineration tail gas of solid hazardous waste has simple process flow, non-fouling equipment, smooth circulation, less equipment, and low operation cost; and the composite rate of removing the harmful substances reaches 98.5%. The heavy metals can be recovered from the bottom dross; the recycle and the harmlessness can be realized without secondary pollutant products.

Owner:重庆太锦环保科技有限公司

White smoke plume elimination system based on upper spraying and upper air inlet spray tower

InactiveCN109772071AImprove heat transfer effectAdjust discharge temperatureUsing liquid separation agentWaste water treatment from gaseous effluentsWater circulationSmoke plume

The invention relates to a white smoke plume elimination system based on an upper spraying and upper air inlet spray tower. The white smoke plume elimination system comprises a spraying subsystem, a water treatment subsystem, a heat pump subsystem, a water circulation subsystem and a smoke reheating subsystem, wherein the water spraying subsystem consists of a spray layer comprising a plurality ofnozzles and a second water pump; the water treatment subsystem consists of a filter tank and a dosing tank which are connected; the heat pump subsystem consists of a compressor, an evaporator, a throttle valve and a condenser which are sequentially connected in series; the cooling water circulation subsystem is composed of a water pool, a first water pump and a connecting pipeline; the smoke reheating subsystem is composed of an air heater, a fan and an air mixing flue; a spraying layer comprising a plurality of nozzles is arranged in the spray tower, and is connected with the cooling water circulation subsystem and the heat pump subsystem through a second water pump; the hot air outlet of the condenser is connected with the mixed flue gas outlet of the spray tower; an outlet of the condensed water and cooling water of the spray tower is connected with the water treatment subsystem; and the dosing pool is connected with the evaporator in the heat pump subsystem; the fan is connected with the condenser in the heat pump subsystem.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

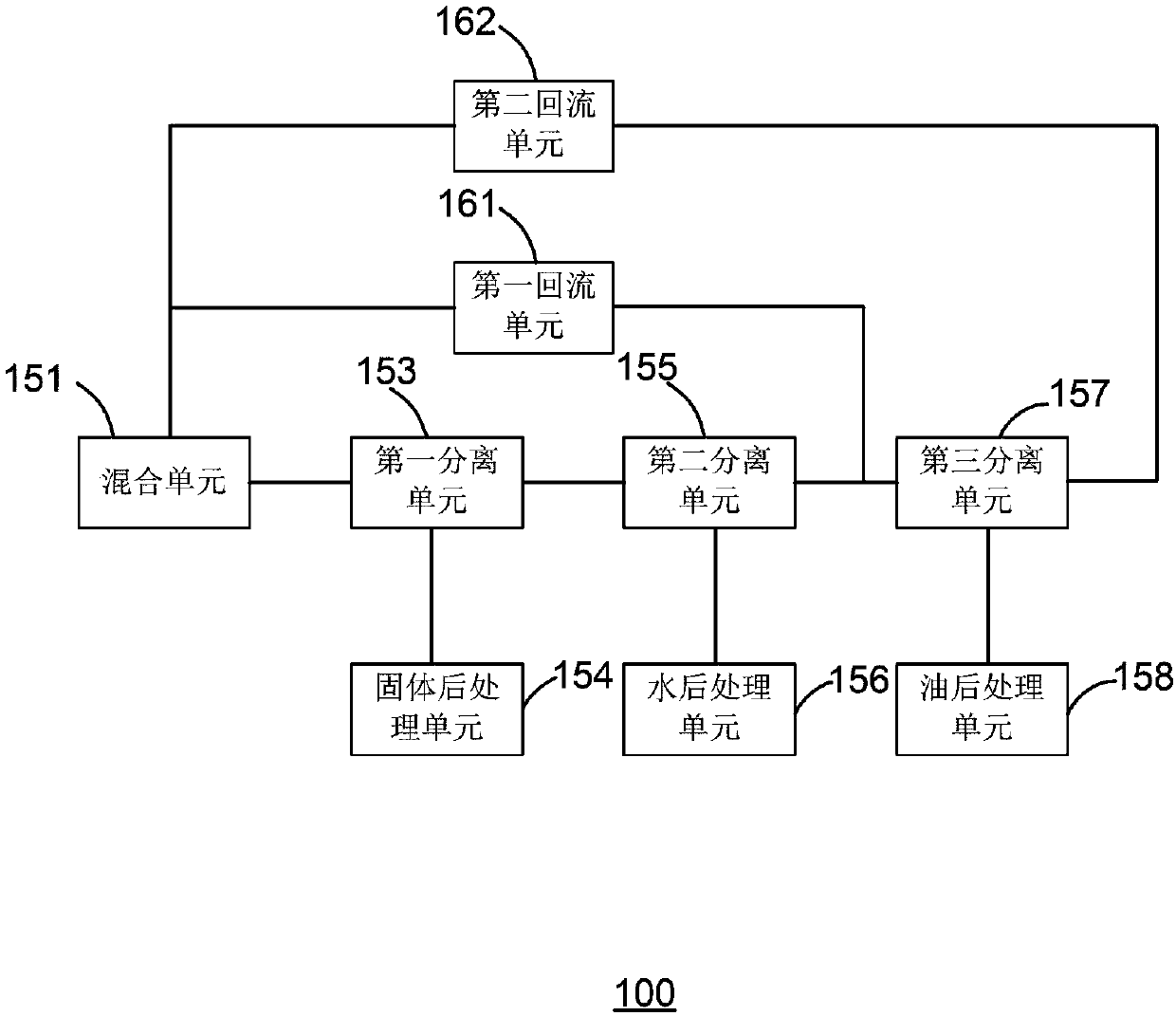

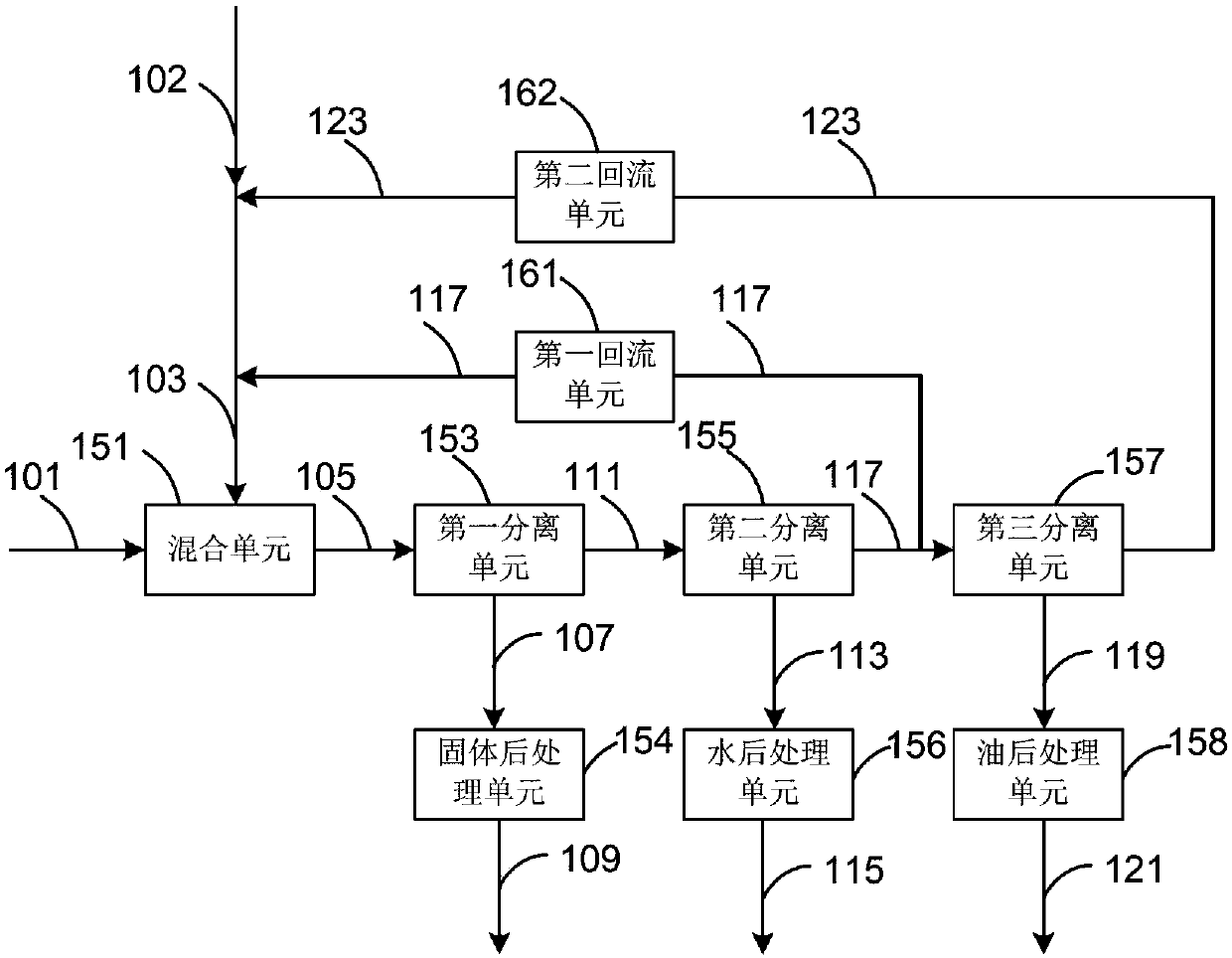

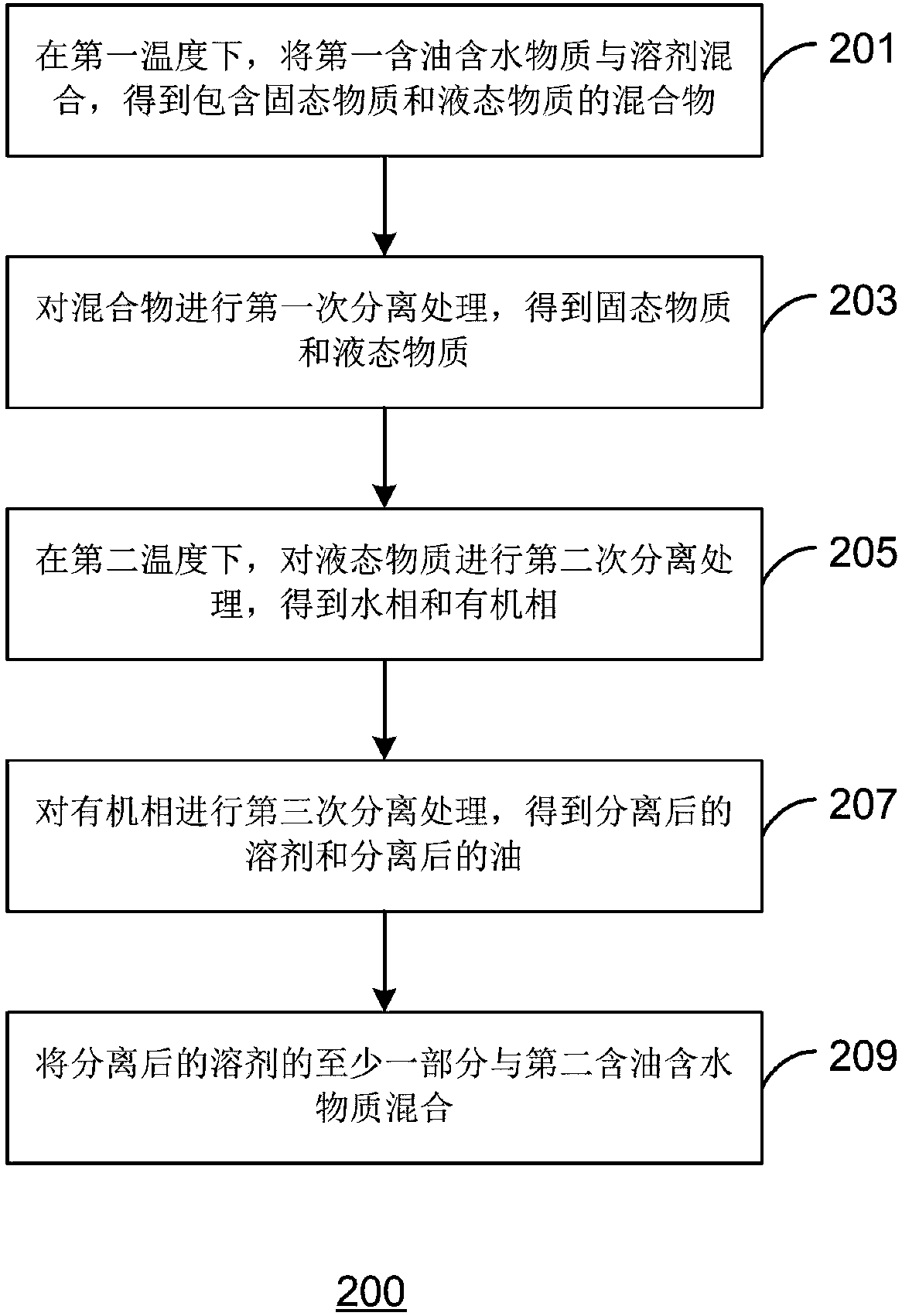

Method and apparatus for treating oil-containing water-containing material

PendingCN110395857AReduce pipe cloggingReduce riskSludge treatment by de-watering/drying/thickeningSolvent extractionLiquid stateSolvent

A method for treating an oil-containing water-containing material includes mixing the oil-containing water-containing material with a solvent at a first temperature to obtain a mixture containing a solid material and a liquid material; subjecting the mixture to a first time of separation to obtain the solid material and the liquid material; subjecting the obtained liquid material to a second timeof separation at a second temperature to obtain a water phase and an organic phase; and subjecting the obtained organic phase to a third time of separation to obtain the separated solvent and separated oil. The intersolubility between the solvent and water at the first temperature is higher than that at the second temperature so that water separation and recovery in the method do not undergo phaseconversion, but are achieved through liquid-liquid separation, thus effectively reducing energy consumption. The invention further relates to a corresponding apparatus.

Owner:北京中科环通工程科技有限公司

Fuel gas injection type recovery method of sensible heat of convertor coal gas and convertor flue gas

ActiveCN102827993AHigh yieldAvoid Forced ReleaseIncreasing energy efficiencyManufacturing convertersRecovery methodCombustion chamber

The invention relates to a fuel gas injection type recovery method of sensible heat of convertor coal gas and convertor flue gas, and belongs to the technical field of recycling sensible heat of convertor coal gas and convertor flue gas. The main technical problems to be solved are as follows: on one hand, the water waste problem is to be solved, on the other hand, efficient utilization of physical sensible heat in the convertor flue gas is to be realized, and the effects of eliminating the potential safety hazard existing in the traditional system, greatly improving the yield of convertor coal gas and the like are also to be achieved. The method comprises allocation of a flue heat exchange device, a rough dust removing device and a refined dust removing device, an induced draft fan, a pipe network a control system, and is characterized in that a combustion chamber is arranged in a recovery system, fuel gas is injected into the combustion chamber, a heat exchanger is also arranged in the recovery system and the heat exchanger is installed behind the combustion chamber. The method is suitable for the technical field of recycling physical sensible heat in the convertor coal gas and convertor flue gas, and has the effects of saving energy, saving water, being safe, improving yield of convertor coal gas and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Convertor coal gas recovery method

ActiveCN102827991AAvoid consumptionStable generationDispersed particle filtrationChemical industryRecovery methodCombustion chamber

The invention relates to a convertor coal gas recovery method, and belongs to the technical field of recycling physical sensible heat in convertor flue gas. The main technical problems to be solved are as follows: on one hand, the water waste problem is to be solved, on the other hand, efficient utilization of physical sensible heat in the convertor flue gas is to be realized, and the problems of sensibility increase of confined explosion caused by due to cancel of an evaporation cooling process and the like are also to be solved. The method comprises allocation of a flue heat exchange device, a rough dust removing device and a refined dust removing device, an induced draft fan, a pipe network a control system, and is characterized in that a combustion chamber is arranged in the method, a heat exchanger is also arranged in the method and the heat exchanger is installed behind the combustion chamber. The method is suitable for the technical field of recycling physical sensible heat in the convertor flue gas, and has the characteristics of saving water, saving energy, improving system safety, improving recovery rate of convertor coal gas and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Sulphonate type ion liquid synthesis method

ActiveCN101759646AAvoid corrosionReduced corrosion protection requirementsOrganic chemistrySynthesis methodsAzeotropic distillation

The invention relates to a sulphonate type ion liquid synthesis method, which comprises the following steps: making organic sulfonate and haloid of imidazole or naphthyridine substituted by C1 to C15 alkyl to sufficiently react in water; carrying out azeotropic distillation to remove water in a reaction system through using sherwood oil, C6 to C8 aromatic hydrocarbon, cyclanes or C4 to C8 ester as entrainers; separating the entrainers from reaction products; then, washing and drying obtained materials; adding extracting agents; and obtaining the sulphonate type ion liquid after removing the extracting agents in the extracting solution. The reaction raw materials used by the method have low price and can be easily obtained, and in addition, strong corrosive materials such as HCL or HBr and the like are not generated in the reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

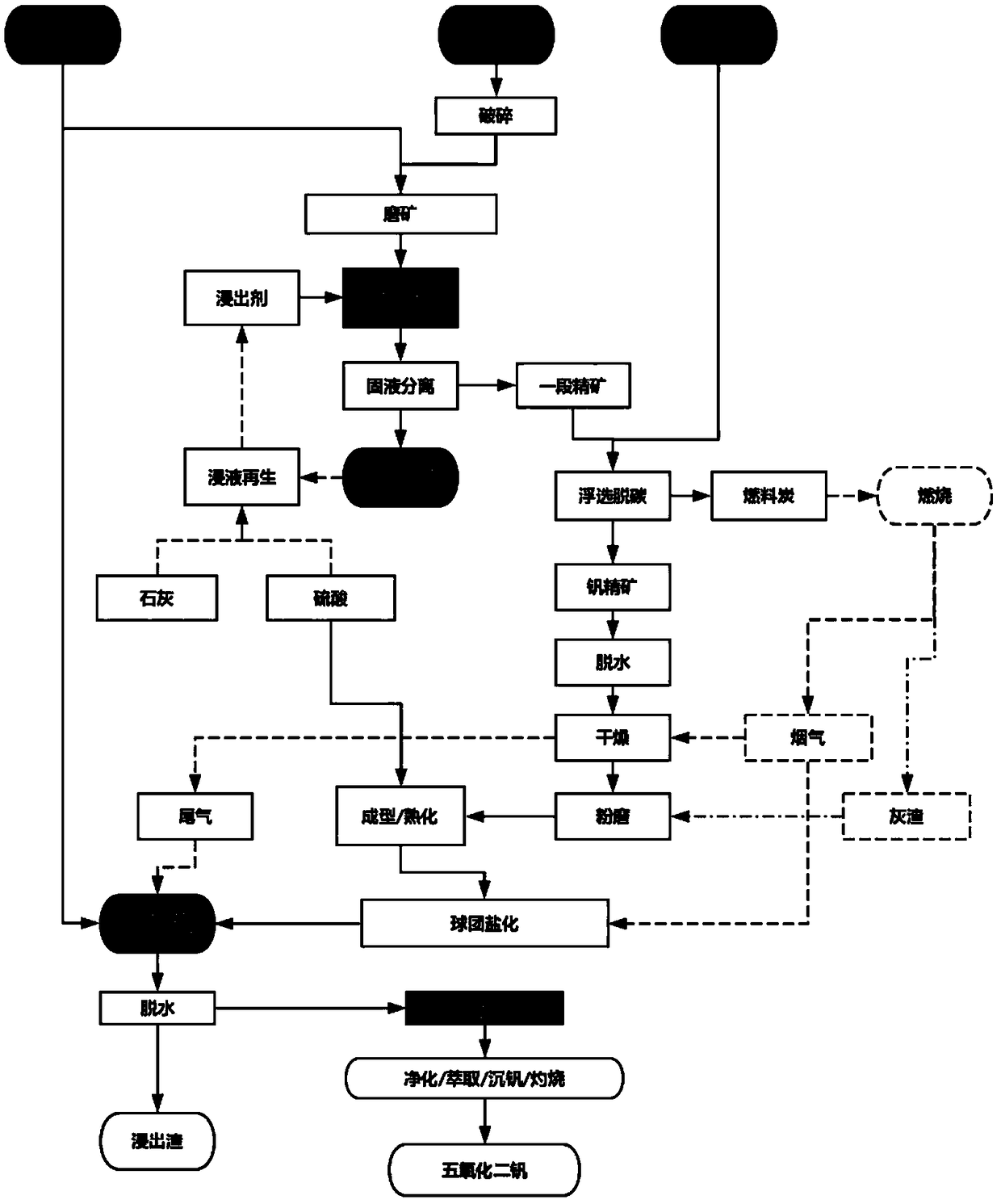

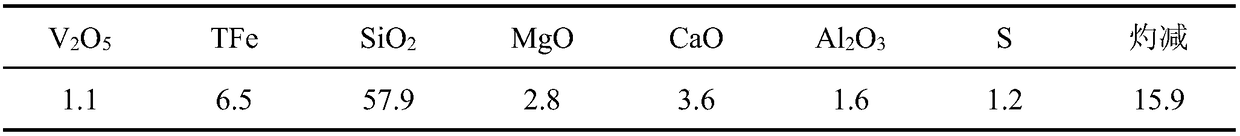

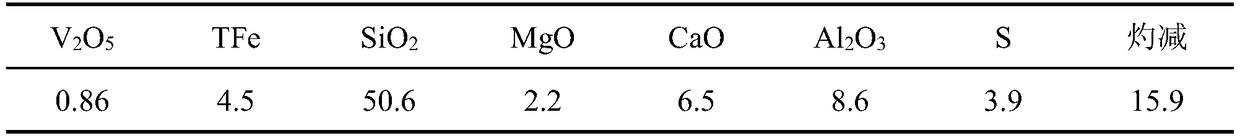

Extraction method of stone coal extracted vanadium

The invention relates to an extraction method of stone coal extracted vanadium. The extraction method comprises the steps that firstly, stone coal is produced to be stone coal ore pulp through pre-treatment procedures of smashing-ore grinding by adding water; low-concentration hydrochloric acid serves as a leaching agent to firstly leach impurities such as potassium, calcium, magnesium and aluminum, and one-stage ore concentrate and one-stage immersion liquid are obtained; the one-stage ore concentrate is floated by using a regulating agent, an inhibitor and a collecting agent, and fuel carbonand vanadium ore concentrate are obtained; the vanadium ore concentrate is dehydrated, dried and ground to be powder, and the ore concentrate dry powder is produced; sulfuric acid serves as an adhesive, the ore concentrate dry powder is shaped and aged in the air; the aged pellet is salinized at the temperature of 200-330 DEG C, vanadium in the pellet is converted to be soluble vanadium sulfate,and a salinized pellet is obtained; and the salinized pellet is subjected to leaching by using water, and second-stage immersion liquid and leached slag are obtained. The leaching rate of vanadium canbe as high as 90-96%, and the industrialized application prospect is good.

Owner:NANHUA UNIV

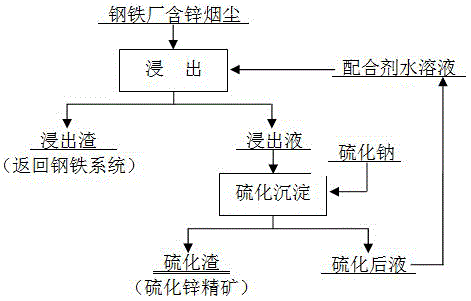

Method for treating steel plant zinc-containing smoke dust through wet process to realize enrichment of zinc sulfide concentrate

InactiveCN104946897ASmall side effectsAchieve deep separationProcess efficiency improvementSlagMaterials science

The invention relates to the field of comprehensive utilization of solid waste resources in a steel plant, in particular to a method for treating steel plant zinc-containing smoke dust through a wet process. According to the method, the steel plant zinc-containing smoke dust is leached through a compounding ingredient aqueous solution with glycine ions Gly<-> as ligand under weak-base conditions, during a leaching process, iron, carbon, calcium, magnesium and silicon are not dissolved and stay in leaching slag, and lead and cadmium enter leaching liquid with zinc; and the leaching slag is returned to a steel system for compounding sintering after water washing, the leaching liquid can be returned to the leaching process to be used after being subjected to sulfide precipitation, and obtained sulfide slag is zinc sulfide concentrate. According the invention, the process is short, and the operation is simple; a leaching system is mild, requirements for corrosion prevention of equipment are low, and less toxic and side effects on human bodies and the environment are realized; ultralow zinc grade zinc-containing smoke dust with high iron content can be treated to realize deep separation of iron and zinc; and toxic heavy-metal elements Zn, Pb and Cd in the steel plant zinc-containing smoke dust can be effectively removed.

Owner:JIANGSU UNIV

Method for selectively recovering lithium from waste lithium ion battery by utilizing ultralow-temperature roasting

ActiveCN113415814ASelectiveLow running costEnergy inputWaste accumulators reclaimingLithium carbonateHigh energy

The invention relates to a method for selectively recovering lithium from waste lithium ion batteries, in particular to a method for selectively recovering lithium from waste lithium ion batteries through ultralow-temperature roasting. The invention aims to solve the problems of high roasting temperature, high energy consumption cost and low recovery efficiency in the existing high-temperature metallurgical recovery process of valuable metals in waste lithium ion batteries, and the technical problems of high consumption of acid, alkali and reducing agents, serious metal loss in the separation process, difficulty in subsequent wastewater and waste liquid treatment and high environmental load in hydrometallurgy. According to the invention, a composite salt is added to selectively destroy the interlayer structure of lithium and oxygen from the positive plate of the lithium ion battery and form the soluble lithium salt, so that selective extraction of lithium ions is realized. The method can be carried out at the ultralow temperature of 300 DEG C, the selectivity to target metal is achieved, the lithium ion recovery rate reaches 90%, and the purity of recovered lithium carbonate reaches up to 95%; and no acid or alkali is added in the whole process, the energy consumption cost is low, and no secondary pollution is generated in the recovery process.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for recovering metal from waste lithium ion battery of nickel cobalt lithium manganate cathode material

ActiveCN104538696BHigh recovery rateReduce recycling costsWaste accumulators reclaimingProcess efficiency improvementHydrogen SulfateFiltration

A method for recycling metal from a waste lithium ion battery with Ni-Co lithium manganite positive electrode materials comprises the steps that the waste lithium ion battery is discharged and disassembled or positive electrode leftover materials and positive electrode fragments are collected to obtain a water positive plate, and roasting, water dissolution and filtration are carried out on the waste positive plate to obtain waste Ni-Co lithium manganite powder; the waste Ni-Co lithium manganite powder and sodium hydrogen sulfate are mixed according to a certain proportion and then roasted, a roasted product is obtained through leaching with water, then a sodium carbonate solution is added into the product solution for filtration, carbonate is supplemented, the proportion of Li, Ni, Co and Mn in filter residues is adjusted for conducting ball milling, compressing and roasting on the filter residues, and the Ni-Co lithium manganite positive electrode materials are obtained again; the components of the filtrate are adjusted with sulfuric acid, and sodium hydrogen sulfate obtained after crystallization treatment is carried out can be utilized again.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

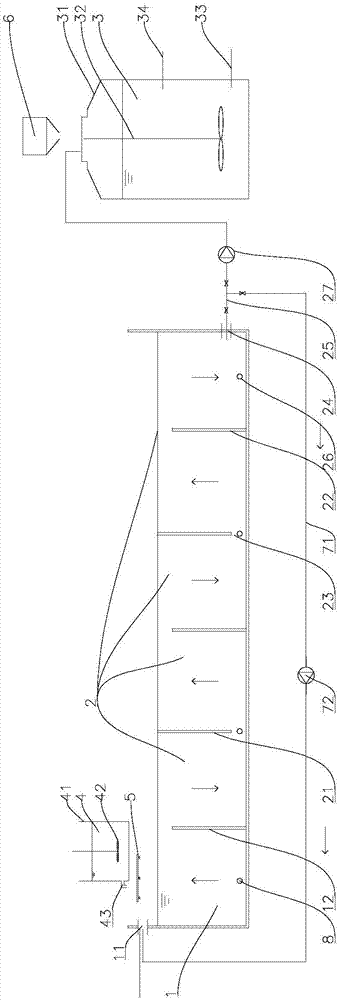

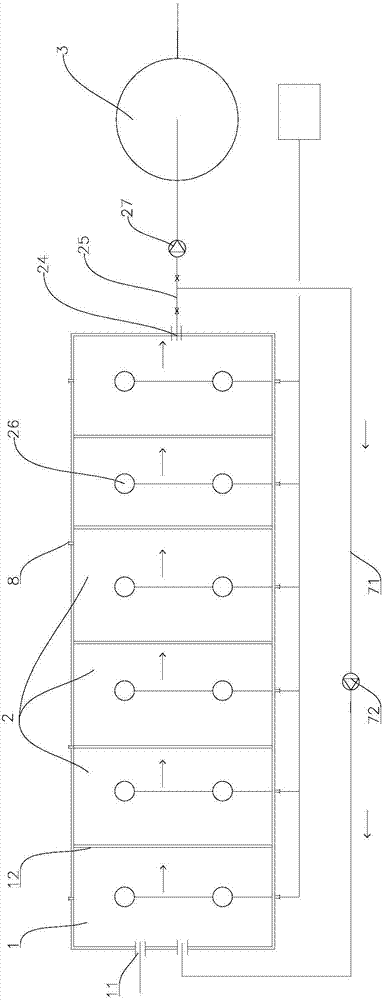

Biological-chemical combined conditioning equipment and method

ActiveCN107056000AGood conditioning effectAvoid shock loadsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesChemical conditionDewatered sludge

The invention relates to the technical field of deep dewatering treatment of sludge, in particular to efficient biological sludge conditioning equipment. The efficient biological sludge conditioning equipment comprises a biological selection pond, a biological leaching reaction pond and a chemical conditioning tank which are arranged in sequence. The biological selection pond is provided with a sludge inlet, a low partition plate is arranged between the biological selection pond and the biological leaching reaction pond, a plurality of upper baffles and lower baffles are alternately arranged in the biological leaching reaction pond, and the biological leaching reaction pond is communicated with the chemical conditioning tank through a sludge outlet pipe; aerators are arranged in the biological selection pond and the biological leaching reaction pond. For the defects in the prior art, a biological-chemical combined conditioning system and method of excess sludge are provided; biological leaching conditioning is conducted on sludge by inoculation of a composite biological leaching strain, strong corrosion of biologically leached sludge is avoided, and the sludge conditioning effect is further ensured; with the assistance of a chemical conditioning agent, the dewatering rate is further increased, and meanwhile the influence of the chemical conditioning agent on the heat value of dewatered sludge is reduced.

Owner:JIANGSU KAIMI MEMBRANE TECH

Method for recovering metals from nickel cobalt lithium manganate waste batteries

ActiveCN104466294BHigh recovery rateReduce recycling costsWaste accumulators reclaimingBattery recyclingHydrogen SulfateFiltration

A method for recycling metal from a waste Ni-Co lithium manganate battery comprises the following steps that the waste Ni-Co lithium manganate battery is discharged and disassembled or positive electrode scrap and positive electrode fragments are collected, a waste positive plate is obtained, calcination, dissolution and filtration are conducted on the waste positive plate, and then waste Ni-Co lithium manganate powder is obtained; the waste Ni-Co lithium manganate powder and potassium hydrogen sulfate are mixed according to a certain proportion and then calcined, a calcined product is leached through water, a potassium carbonate solution is added into a solution, filtration is conducted, carbonate is supplemented to adjust the proportion of Li, Ni, Co and Mn in a filter residue, ball grinding, compression and calcination are conducted on the filter residue, and the Ni-Co lithium manganate positive electrode material is obtained again. Constituent adjustment is conducted on filtrate through sulfuric acid, and potassium hydrogen sulfate obtained after crystallization can be reused.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com