Extraction method of stone coal extracted vanadium

A stone coal and leaching technology, applied in the direction of improving process efficiency, can solve the problems of large pollutant discharge, low leaching rate, and complex vanadium occurrence forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

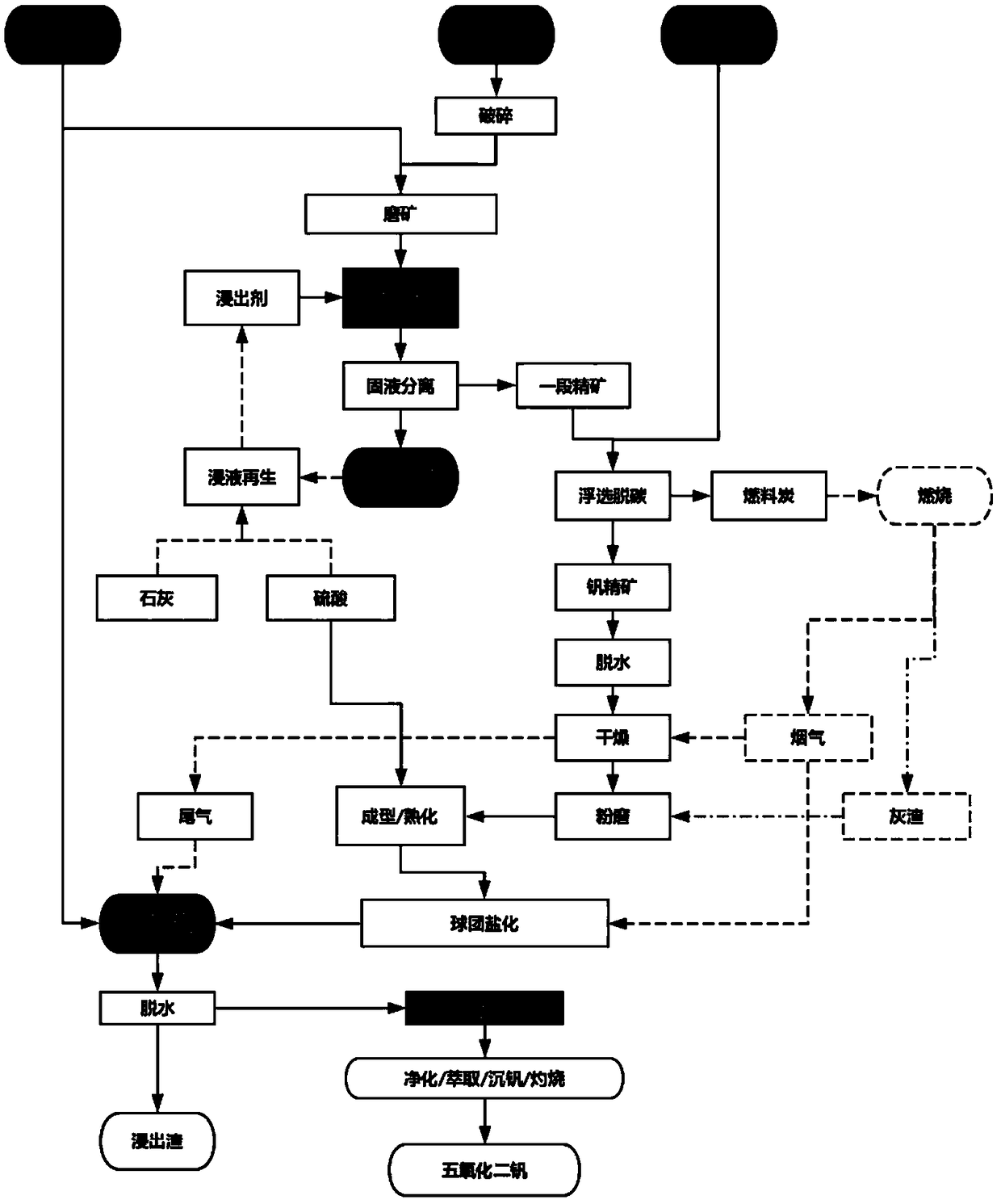

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1: a kind of leaching method of extracting vanadium from stone coal, concrete operations are as follows:

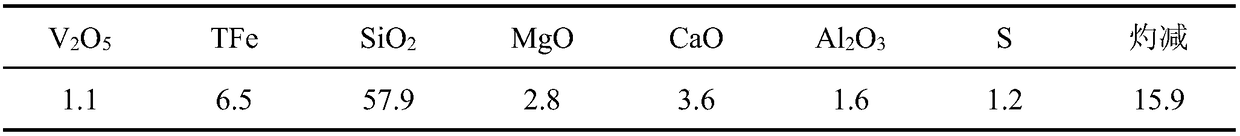

[0090] A stone coal vanadium mine in Huaihua, Hunan, the mass percentage of its chemical composition is:

[0091] Table 1 Raw ore multi-element analysis results / %

[0092]

[0093] After the ore is crushed, water is added to grind the ore to obtain a stone coal slurry with a particle size of -74 μm accounting for more than 85% and a liquid-solid ratio of 2.

[0094]Add the above-mentioned stone coal slurry into the leaching tank, at 300r.min -1 Under stirring, add a leaching agent with a mass concentration of 5% HCl evenly, keep the pH value of the pulp in the range of 3.5-4.0, leaching for 3 hours, and settle the leaching slurry for 1 hour, release the upper leachate, and the bottom is a section of concentrate; test this The leaching rate of step vanadium is 1.2%, and the leaching rate of iron is 2.1%.

[0095] Add water to a section of concentrat...

Embodiment 2

[0100] Embodiment 2: a kind of leaching method of extracting vanadium from stone coal, concrete operations are as follows:

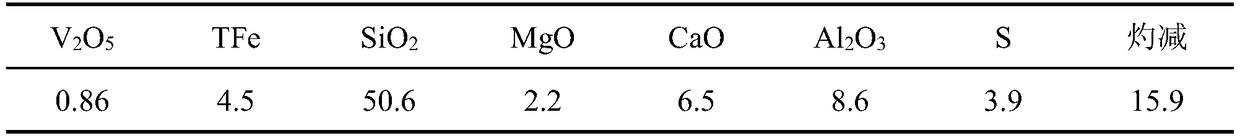

[0101] A leaching test was carried out on a high-calcium stone coal-vanadium mine in Tongshan, Hubei. V in this mineral 2 o 5 The content is 0.86%. The gangue minerals are mainly mica, calcite, dolomite and pyrite. The composition is as follows:

[0102] Table 2 Stone coal mine multi-element analysis results / %

[0103]

[0104] S1: After the ore is crushed, water is added to grind the ore to obtain a stone coal slurry with a particle size of -74 μm accounting for 86.5% and a liquid-solid ratio of 3.

[0105] S2: Add the above-mentioned stone coal slurry into the leaching tank, at 200r·min -1 Under stirring, evenly add a leaching agent with a mass concentration of 6.0% HCl, keep the pH value of the ore slurry in the range of 6-6.8, leaching for 4 hours, press filter the leaching slurry, and obtain a section of leaching solution and a section of con...

Embodiment 3

[0112] Compared with Example 2, the only difference is that in S2, the pH value of the slurry is controlled within the range of 2.0-3.0, leached for 4 hours, and the leached slurry is subjected to pressure filtration to obtain a section of immersion solution and a section of concentrate, and detect the vanadium in this step. The leaching rate of iron is 3.1%, the leaching rate of iron is 3.3%, and the leaching rate of calcium is 98.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com