Fuel gas injection type recovery method of sensible heat of convertor coal gas and convertor flue gas

A converter gas and converter flue gas technology, which is applied to furnaces, furnace components, waste heat treatment, etc., can solve the problems of large initial investment, high operating costs, high maintenance costs, waste, etc., to reduce initial investment and operating costs, and reduce operating costs High, avoid water consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

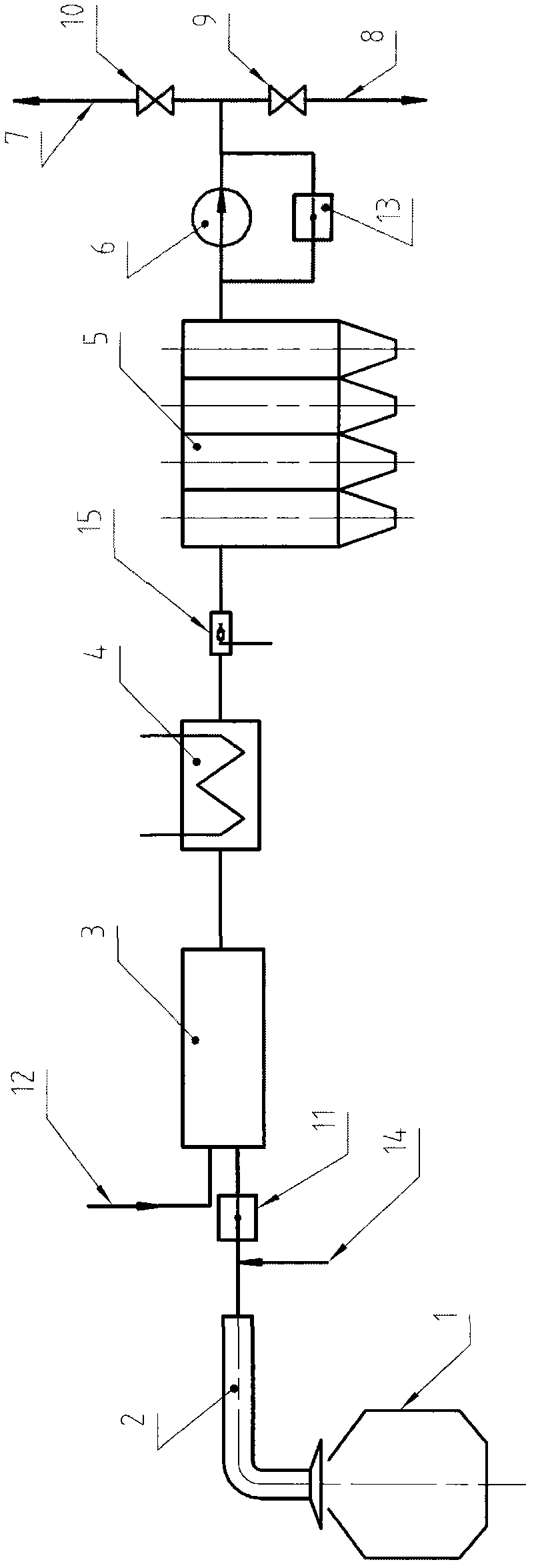

[0038] Example 1, such as figure 1 shown.

[0039] exist figure 1Among them, 1 is the converter. 2 is the flue heat exchange device of the converter. 3 is a combined device that is integrated and has the functions of rough dust removal, heat storage and combustion chamber. 4 is a heat exchange device. 5 is a fine dust removal device, specifically, it is a bag filter. 6 is blower fan. 7 is a recovery channel for converter gas. 8 is the combustion release channel of the converter gas, so as to facilitate emergency and / or release residual gas that does not have recovery value. 9 and 10 are control valves arranged on the release passage 8 and the recovery passage 7 respectively. 11 is an on-off valve installed between the combined device 3 and the flue heat exchange device 2. It is not difficult to see that the on-off valve 11 also conforms to the characteristics of being arranged before the combustion chamber or the regenerative combustion chamber, because in this embod...

Embodiment 2

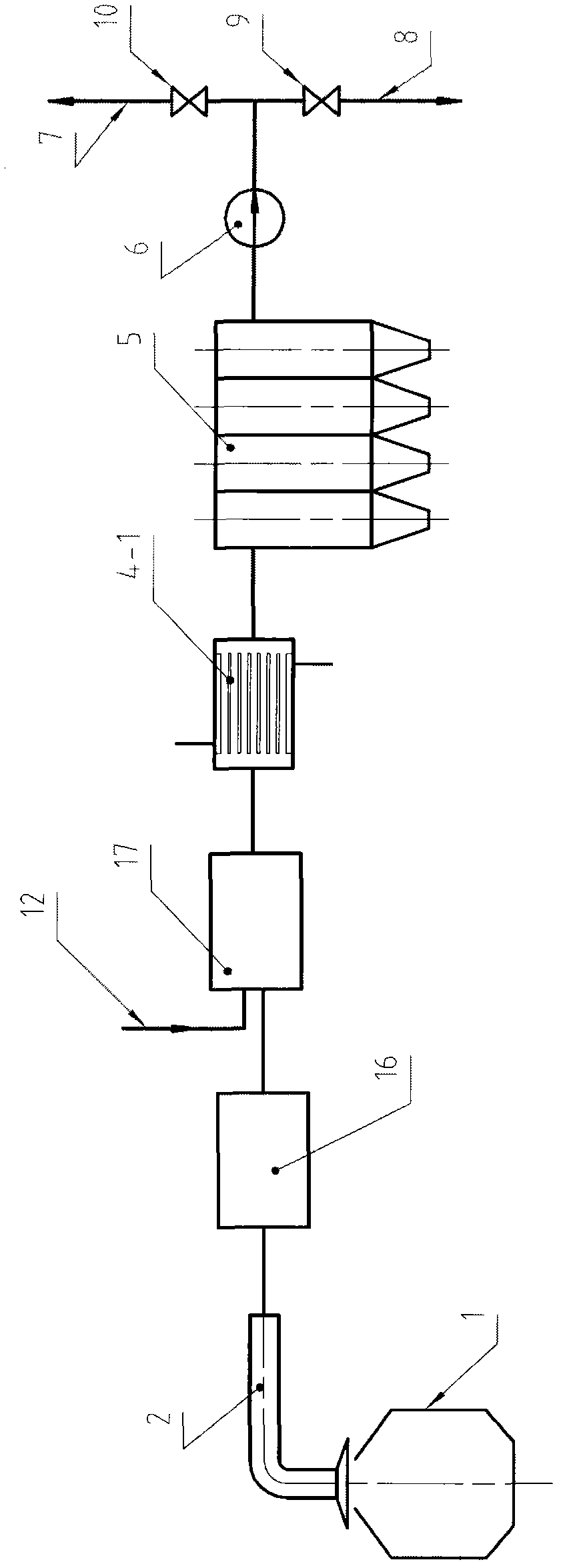

[0076] Example 2, such as figure 2 shown.

[0077] This embodiment is a simplification of Embodiment 1.

[0078] Compared with embodiment 1, it cancels the input channel 14 of combination device 3, switch valve 11, inert gas, blower fan 6 backflow switch valve 13 and water mist generator 15; and a separate combustion chamber 17 to replace the combination device 3; meanwhile, the heat exchange device 4 is replaced with a fire tube heat exchange device 4-1. The separate coarse dust collector 16 and the separate combustion chamber 17 are preferably also provided with a heat storage function, so as to obtain better use effects.

[0079] The working process of this embodiment is: the converter flue gas discharged from the flue heat exchange device 2 first enters the separate coarse dust collector 16 for preliminary dust removal, and keeps the coarse dust collector 16 at a relatively high temperature, and can carry out dedusting in it. The continued reaction of the gas and residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com