Method and apparatus for treating oil-containing water-containing material

A technology for substances and liquid substances, applied in the field of separation of mixtures, can solve the problems of complicated and uneconomical extraction of petroleum or asphalt, and achieve the effects of reducing the risk of clogging pipelines and subsequent steps, reducing processing costs, and reducing anti-corrosion requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

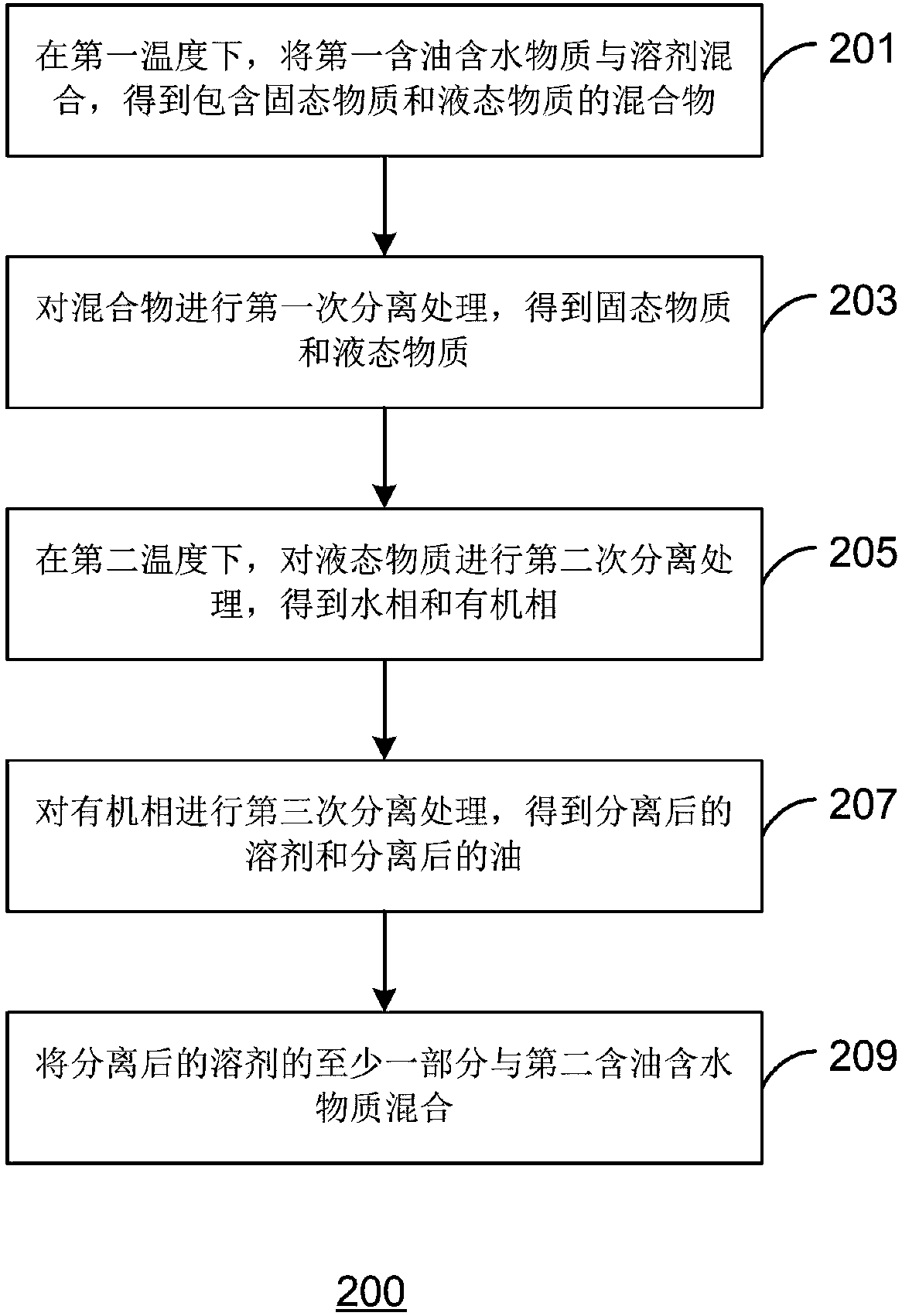

[0094] A small device with a processing capacity of 100 g per batch of samples was used to treat the scum and sludge with triethylamine as a solvent. The water content, oil content and ash content of the scum and sludge are shown in Table 1. Among them, ash refers to the inorganic matter in the sample except water.

[0095] In a mixer with stirring function, under normal pressure and 30° C., 100 g of scum oil sludge and 200 g of triethylamine were added and stirred for 5 minutes for mixing. Then, the mixture in the mixer is drained into the filter for filtration, the filter cloth has a pore size of 5 microns, pressurized to 5 bar with compressed air or compressed nitrogen, collects the separated solid on the filter cloth, and filters out, containing The liquid substances of triethylamine, water and oil are introduced into the liquid-liquid separator. In the liquid-liquid separator, maintain normal pressure, raise the temperature of the mixture of triethylamine, water and oil ...

example 2

[0100] Firstly, the scum and sludge are pretreated and dehydrated. The pre-dehydration is dehydrated by pressure filtration, and the filter cloth with a pore size of 5 microns is used under 4 standard atmospheric pressures. The filtered water phase is clear and transparent, and no oil components and ash are detected. . The scum and oil sludge after pre-dehydration is relatively dry, and the reduction is over 90%. The water content, oil content and ash content of the scum oil sludge after pre-dehydration are shown in Table 2.

[0101] A small device with a processing capacity of 100 g per batch of samples is used to treat the pre-dehydrated scum and oil sludge with triethylamine as a solvent.

[0102] In a mixer with stirring function, under normal pressure and 30° C., 100 g of pre-dehydrated scum oil sludge and 200 g of triethylamine were added and stirred for 5 minutes for mixing. Next, the mixture in the mixer is drained into the filter for filtration, the filter cloth has...

example 3

[0107] A small device with a processing capacity of 100 g per batch of samples was used to treat the tank bottom sludge with triethylamine as a solvent. The water content, oil content and ash content of the tank bottom sludge are shown in Table 3.

[0108] In a mixer with stirring function, under normal pressure and 30° C., 100 g of tank bottom sludge and 500 g of triethylamine were added and stirred for 5 minutes for mixing. Then, the mixture in the mixer is drained into the filter for filtration, the filter cloth has a pore size of 50 microns, pressurized to 5 bar with compressed air or compressed nitrogen, collects the separated solid on the filter cloth, and the filtered, containing The liquid substances of triethylamine, water and oil are introduced into the liquid-liquid separator. In the liquid-liquid separator, maintain normal pressure, raise the temperature of the mixture of triethylamine, water and oil to 80°C, keep it stable for about 10 minutes, and divide it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com