Biogas desulfurization and deodorization device and method

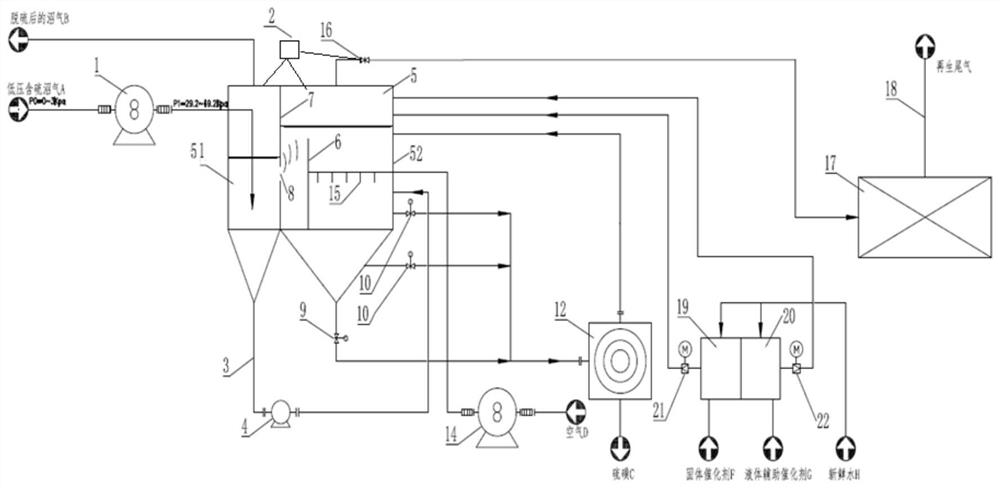

A biogas desulfurization and biogas technology, which is applied in the preparation/purification of sulfur, gas fuel, petroleum industry, etc., can solve the problems of inability to achieve filtration, strong odor, health of operators and damage to the surrounding environment, and achieve high-precision desulfurization. requirements, low energy consumption, efficient, safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Configure desulfurization liquid and inject it into the desulfurization device

[0076] The desulfurization catalyst (production batch number 20200410) developed by Sichuan Binghui Environmental Protection Technology Co., Ltd. is selected. It is composed of a solid catalyst and a liquid auxiliary catalyst. First, the solid catalyst F is dropped into the first dissolving tank 19, and then the fresh water H is used to dissolve and then added to the regeneration chamber 52 with the pump 21; the liquid auxiliary catalyst G is dropped into the second dissolving tank 20, and then fresh water H is used to dissolve The water H is properly diluted and added to the regeneration chamber 52 with the pump 22 . Finally, add fresh water H to the entire desulfurization device until it is higher than the partition 6 of the regeneration tank.

[0077] (2) Biogas desulfurization

[0078] The low-pressure biogas A (with a pressure of 0-3Kpa) containing hydrogen sulfide at a concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com